Automatic surface grinder for crystal glass

A crystal glass and surface grinding machine technology, applied in machine tools, grinders, grinding/polishing equipment suitable for grinding workpiece edges, etc., can solve problems such as rising production costs, easy deviations in distances and angles, and reducing production efficiency. , to achieve the effect of reducing production costs, simple and convenient operation, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

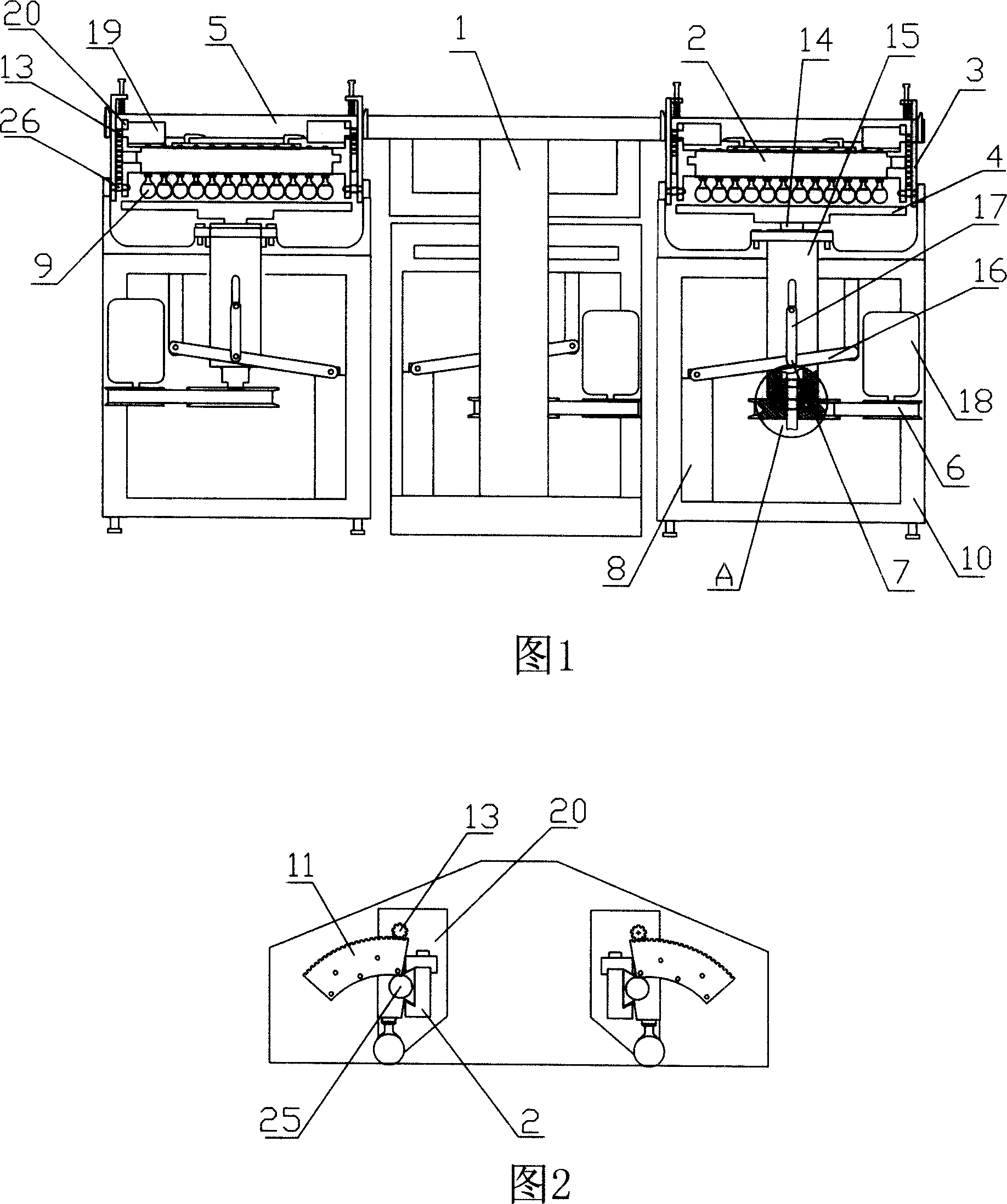

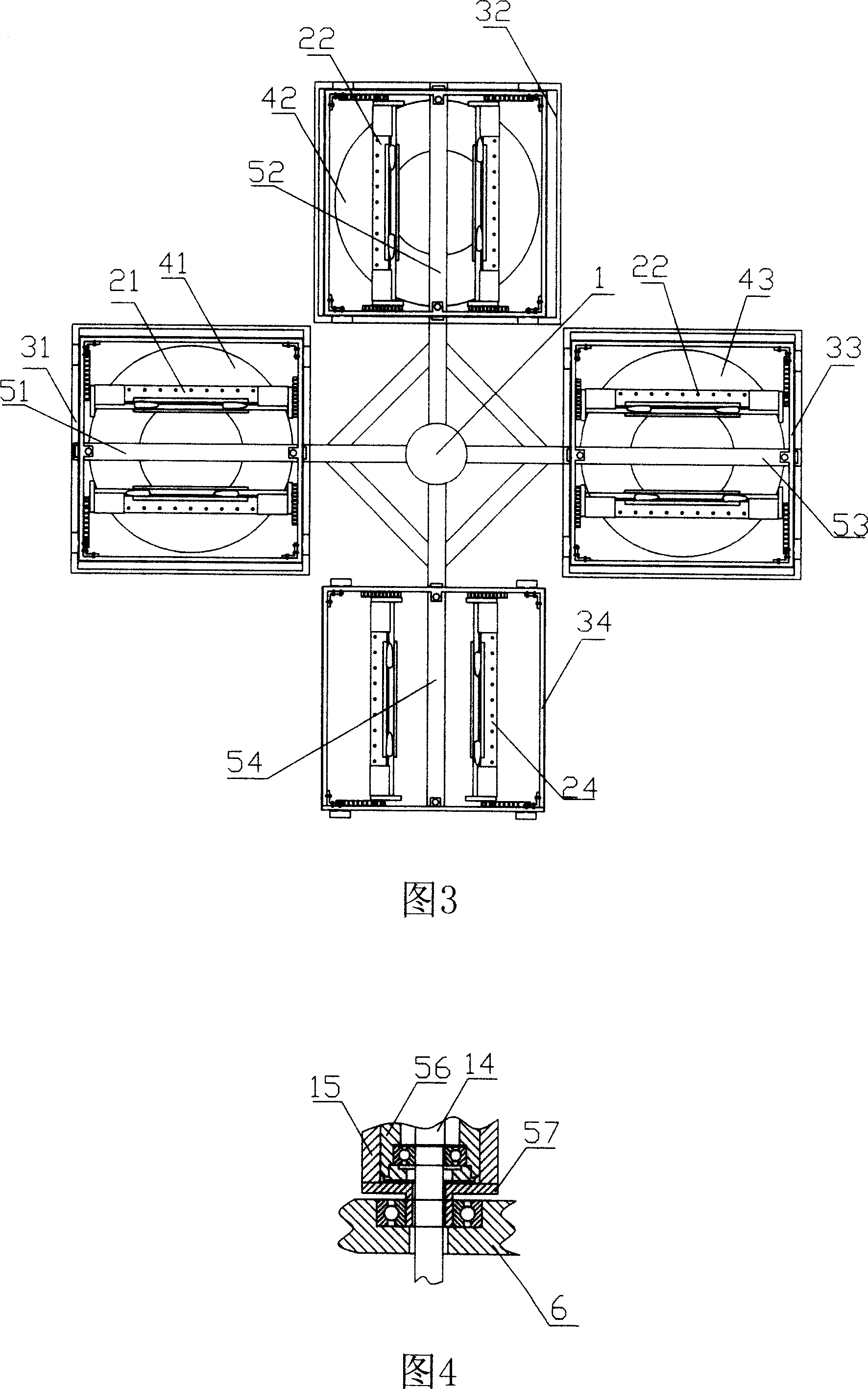

[0018] A detailed description of the specific implementation of the present invention will be made below in conjunction with accompanying drawings 1-4.

[0019] A kind of fully automatic crystal glass grinding machine shown in Fig. 1, Fig. 2, Fig. 3, Fig. 4 is made of rotating control frame 1, 3 frames 10, 4 heads 3 matched with frame 10. The rotating control frame 1 is provided with 4 support arms 5 matching the number of the machine heads 3, and the 4 support arms 5 are regularly arranged in 4 directions according to 90 degree angles, and the 4 machine heads 3 are fixed below the support arms 5, And the four heads 3 are on the same horizontal plane. Each frame 10 is respectively equipped with a grinding disc 4, a motor 18 for controlling the rotation of the grinding disc 4, and an air cylinder 8 for controlling the lifting of the grinding disc 5.

[0020] Wherein, a conduit sleeve 15 is fixed on the frame 10 , and a conduit 56 is arranged inside the conduit sleeve 15 , and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com