Intermittent motion transmission mechanism

A technology of transmission mechanism and motion, applied in transmission devices, mechanical equipment, belts/chains/gears, etc., can solve problems such as noise generation, bolt 3 breakage, bolt 3 shear damage, etc., to achieve average force and reduce structural damage , the effect of good contact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to illustrate the present invention more clearly, preferred embodiments are given and described in detail in conjunction with the accompanying drawings as follows.

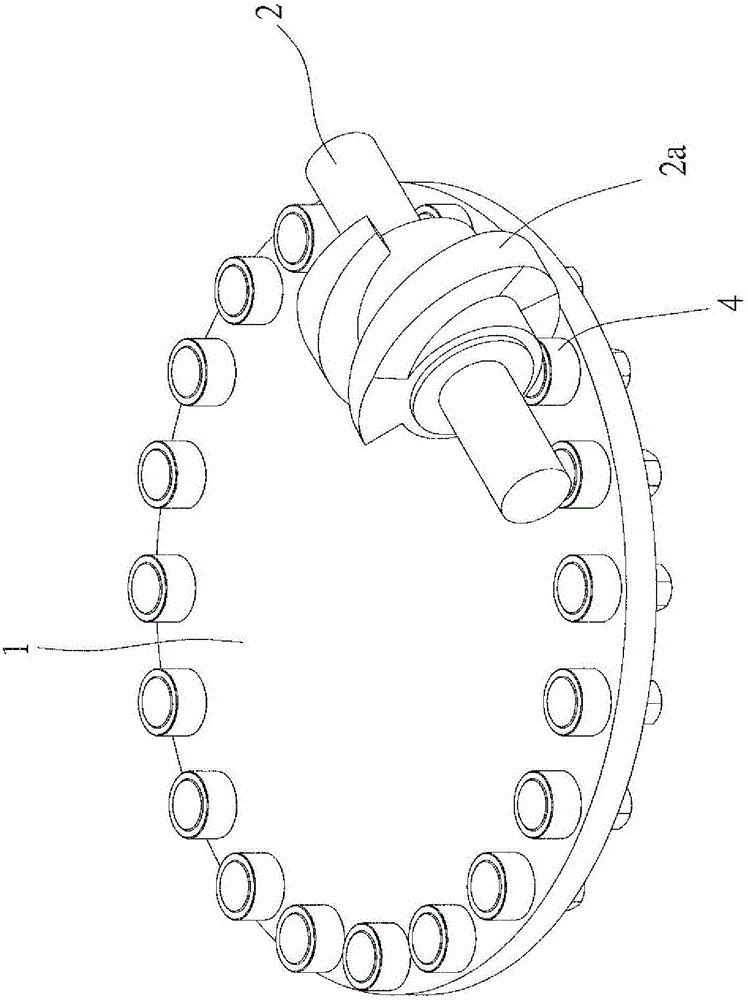

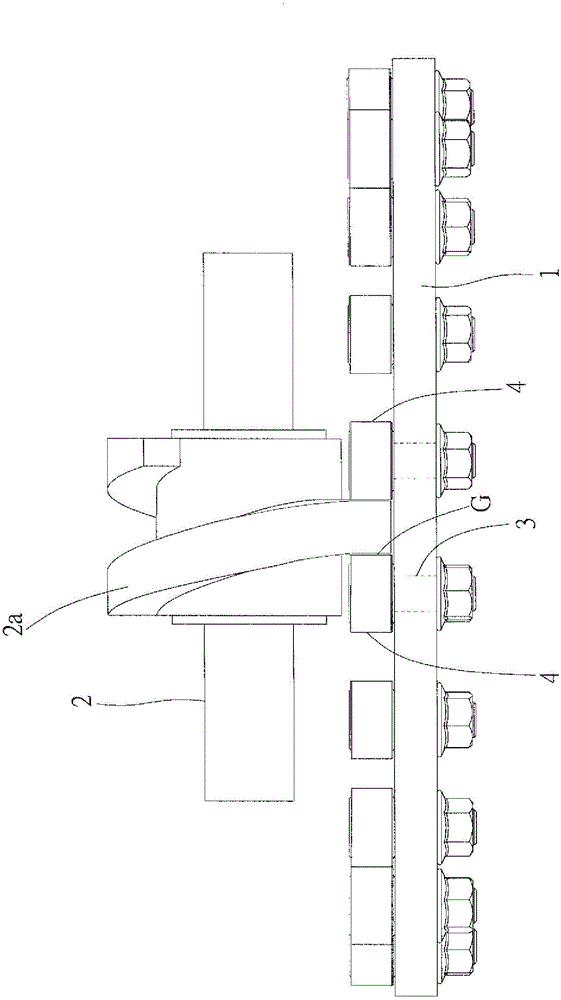

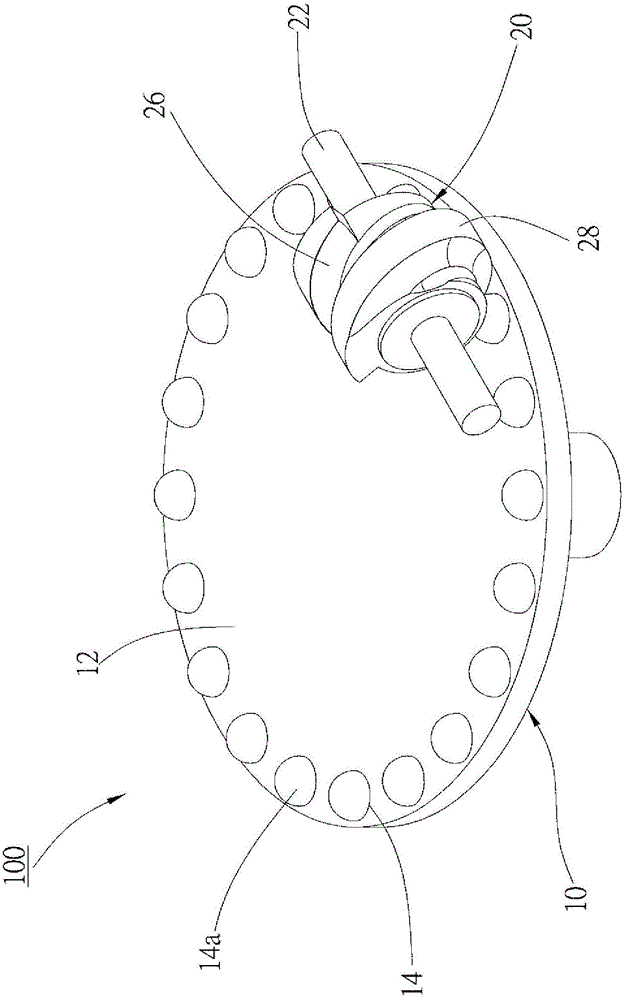

[0016] see Figure 3 to Figure 5 Shown is an intermittent motion transmission mechanism 100 according to a preferred embodiment of the present invention. The transmission mechanism 100 is applied to a processing tool and includes a rotating disk 10 and a camshaft 20 . Wherein the rotating disk 10 is a disk-shaped body, and its disk surface 12 is provided with a plurality of contact pieces 14 at equal intervals along the circumferential direction, and each of the contact pieces 14 has a hemispherical portion 14a exposed outside the disk surface 12 . In this embodiment, it is preferable that each contact piece 14 is accommodated in the corresponding arc-shaped recess 16 of the rotating disk 10 in the form of a spherical body.

[0017] The camshaft 20 of the transmission mechanism 100 is disposed abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com