Method for improving percussion drilling capability of screw drill and pulse screw

A technology of screw drilling tools and percussion drilling, which is applied to drilling equipment, vibration drilling, and driving devices for drilling in boreholes. It has the effect of percussion drilling ability, increasing output torque and rotating speed, and improving drilling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

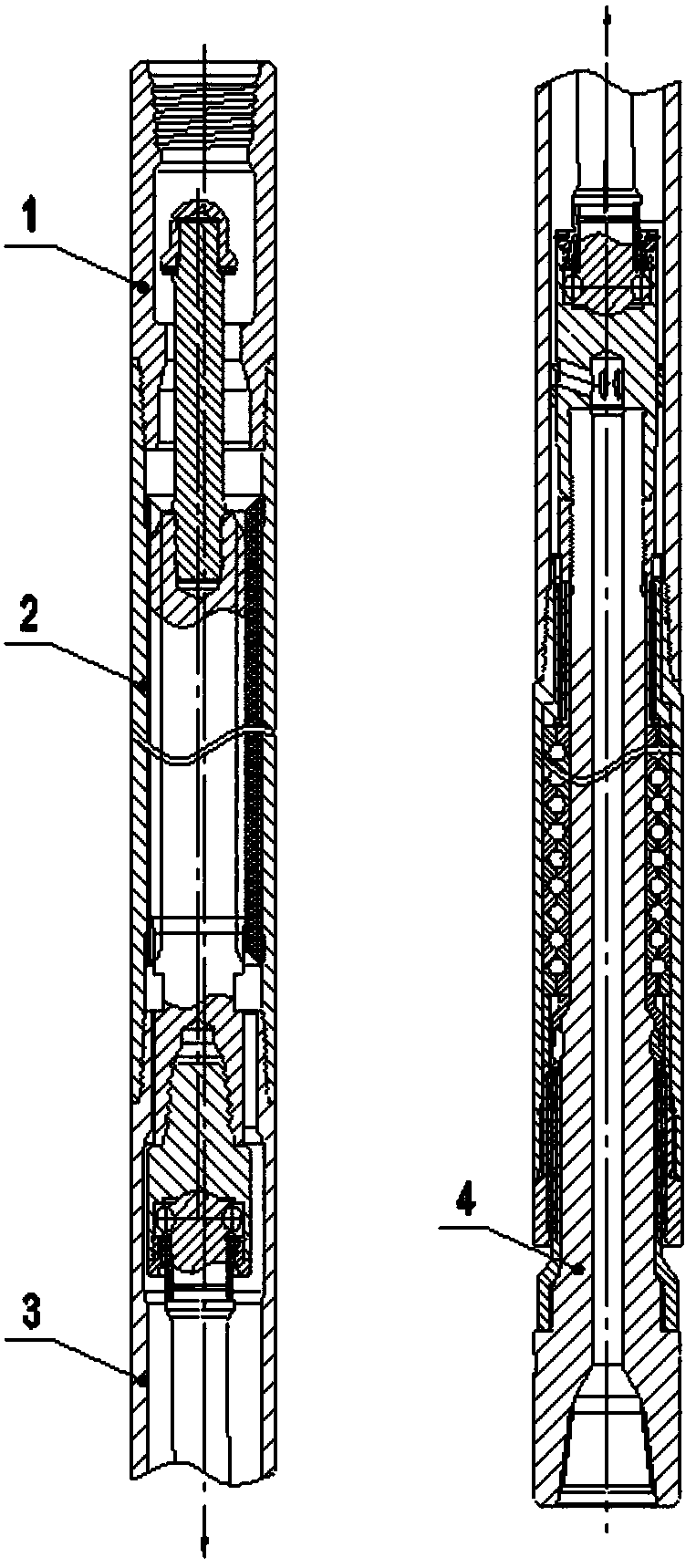

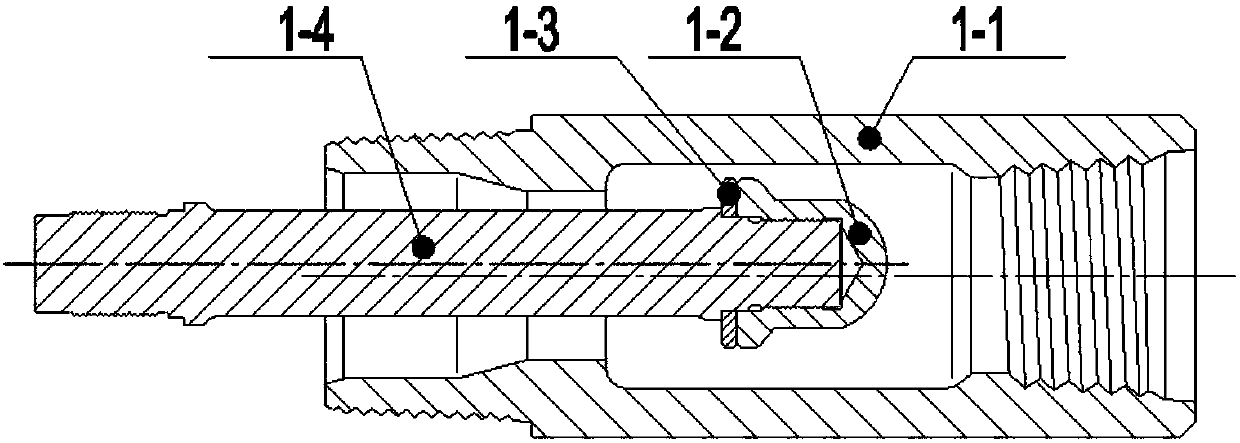

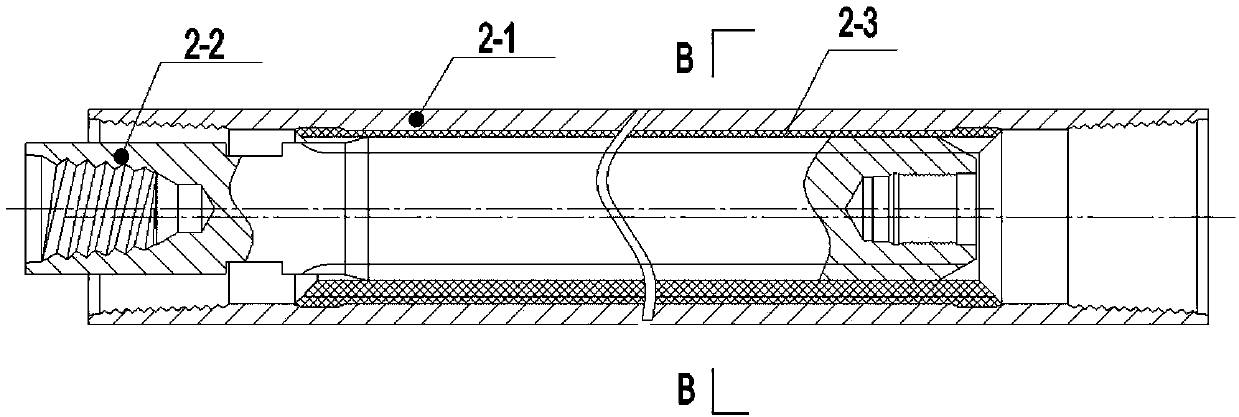

[0025] Embodiment of the present invention: a method for improving the percussion drilling capability of a screw drilling tool. The method improves the motor assembly 2 and the pulse cardan shaft assembly 3 in the screw drilling tool so that it has hydraulic pulse jet and shaft The function of high-frequency impact, thereby improving the impact drilling ability of the screw drilling tool; the stator 2-1 and the rotor 2-2 of the motor assembly 2 adopt a spiral structure, thereby extending the lead of the motor assembly 2 and increasing The number of stages of the motor assembly 2 and the number of heads of the stator and rotor, while increasing the displacement of the mud pump system, can increase the output torque and speed of the motor assembly 2; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com