Carbon dioxide rock breaking device and method for open-pit mine

A carbon dioxide and rock-breaking device technology, which is applied in open-pit mining, blasting, earthwork drilling and mining, etc., can solve the problems of difficulty in meeting the block size requirements of different ore and rock bodies, aggravating energy dissipation and dust pollution, and inability to carry out energy. , to achieve the effect of improving the grade of mineral resources, increasing the range and energy of rock breaking, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

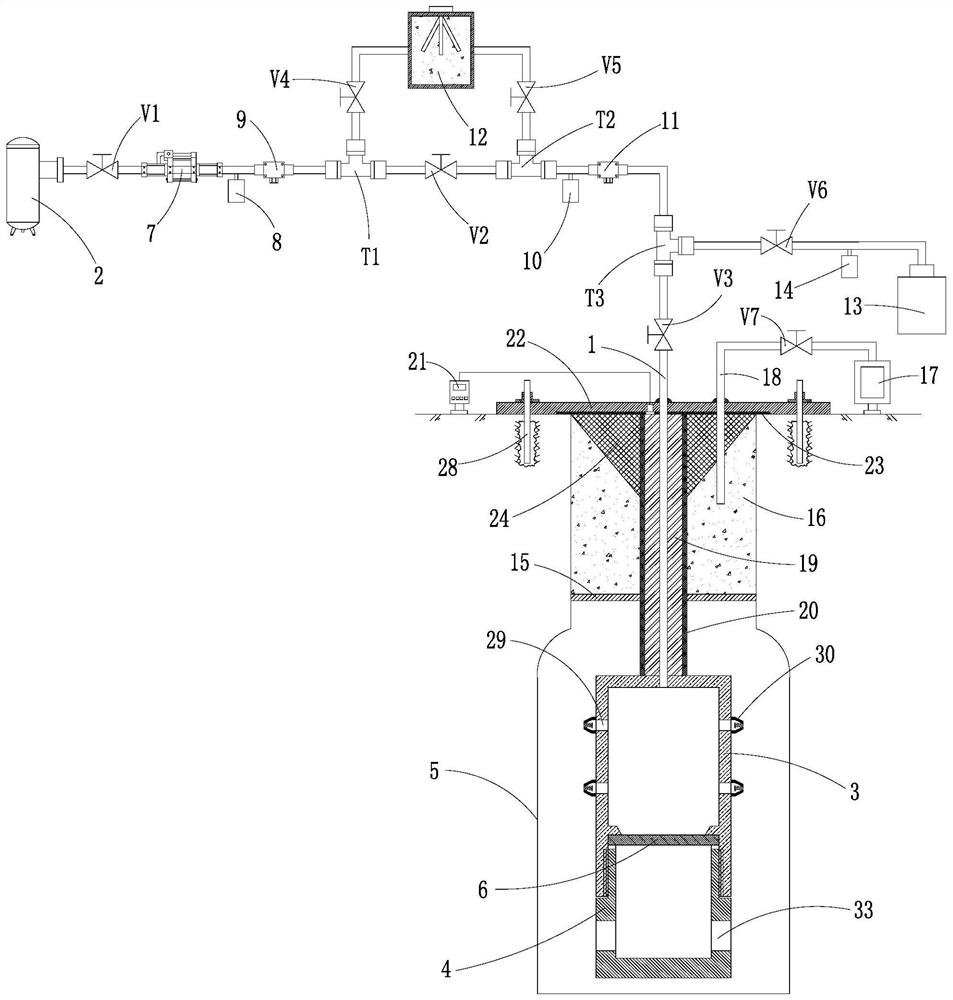

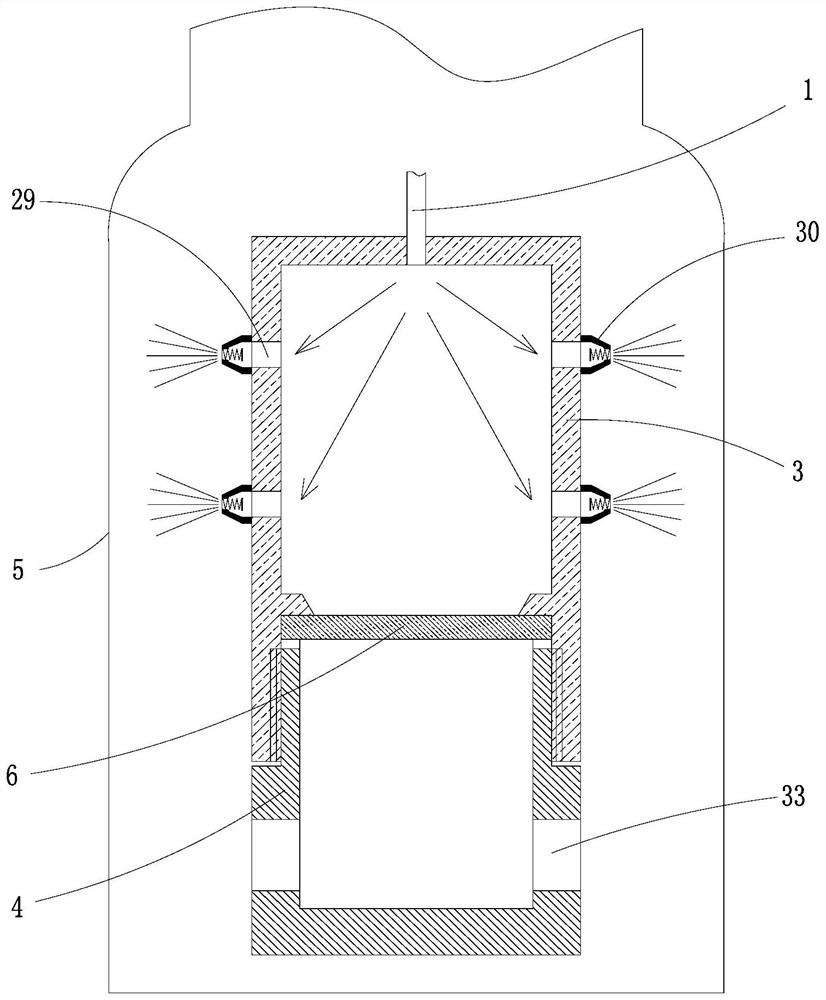

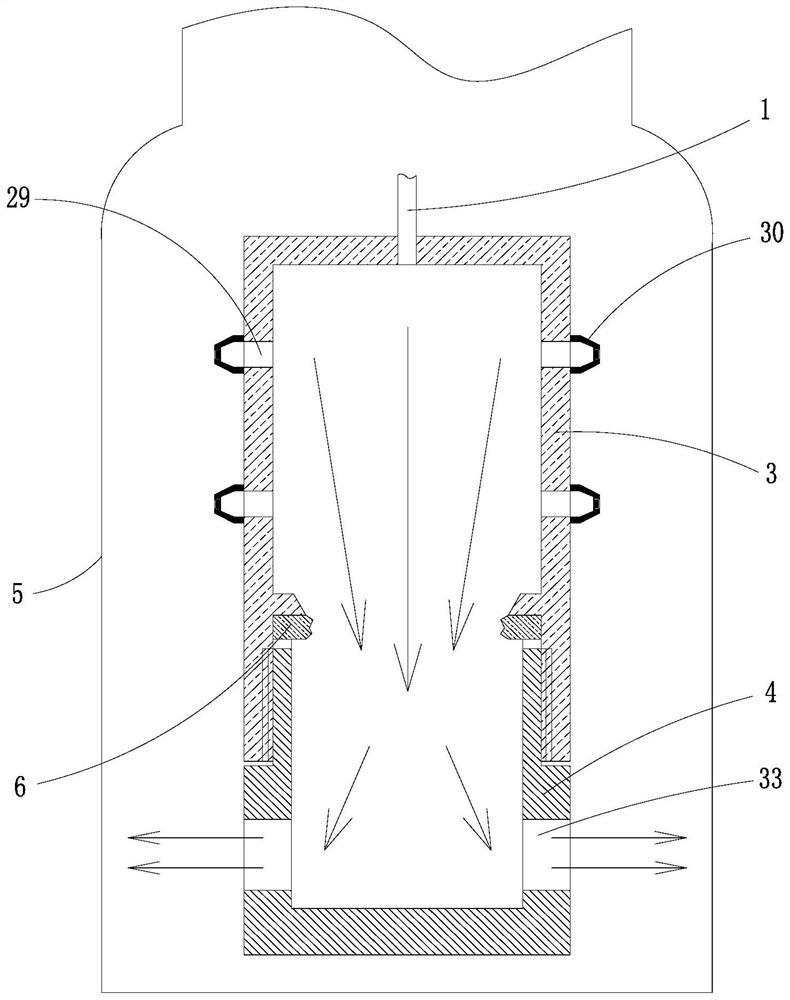

[0037] Such as Figure 1-6 As shown, a carbon dioxide rock-breaking device for open-pit mines includes a gas injection pipe 1, a liquid carbon dioxide storage tank 2, an energy storage chamber 3 and a fracturing chamber 4; the liquid carbon dioxide storage tank 2 is located outside the borehole 5, and the storage tank The energy chamber 3 and the fracturing chamber 4 are located inside the borehole 5; one end of the gas injection pipe 1 communicates with the liquid carbon dioxide storage tank 2, the other end of the gas injection pipe 1 communicates with the energy storage chamber 3, and the energy storage chamber 3 communicates with the The cracking chambers 4 are arranged in series, and the inner cavity of the energy storage chamber 3 and the cracking chamber 4 is separated by a sealing sheet 6 .

[0038] A first valve V1, a booste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com