Preparation method of environment-friendly hydrophobic polyurethane grouting material

An environmentally friendly, grouting material technology, used in mining equipment, shaft equipment, earth-moving drilling and other directions, can solve the problems of natural environment pollution and high toxicity, reduce negative effects, use safety, and benefit health and environmental protection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Prepare environment-friendly hydrophobic polyurethane grouting material of the present invention according to the following steps

[0036] ①. Preparation of polyurethane prepolymer

[0037] Accurately weigh 30 parts by weight of polyether diol DL-1 with a number average molecular weight of 400, and 3 parts by weight of ethylene glycol, put them into the reaction kettle, and carry out negative pressure dehydration and degassing treatment for 3 hours under stirring, and cool down to 40±2 After ℃, add 200 parts by weight of polymethylene polyphenyl polyisocyanate PAPI PM-200, and carry out polymerization reaction for 3 hours at a temperature of 80±2℃, and control the -NCOwt% content of the prepolymer between 20% and 35%. is the end point of the reaction;

[0038] ②. Cool down, add additives

[0039] In the polyurethane prepolymer prepared in step ①, add 10 parts by weight of diglyme, fully dissolve under stirring, then add 0.003 parts by weight of phosphoric acid, 9 part...

Embodiment 2~ Embodiment 4

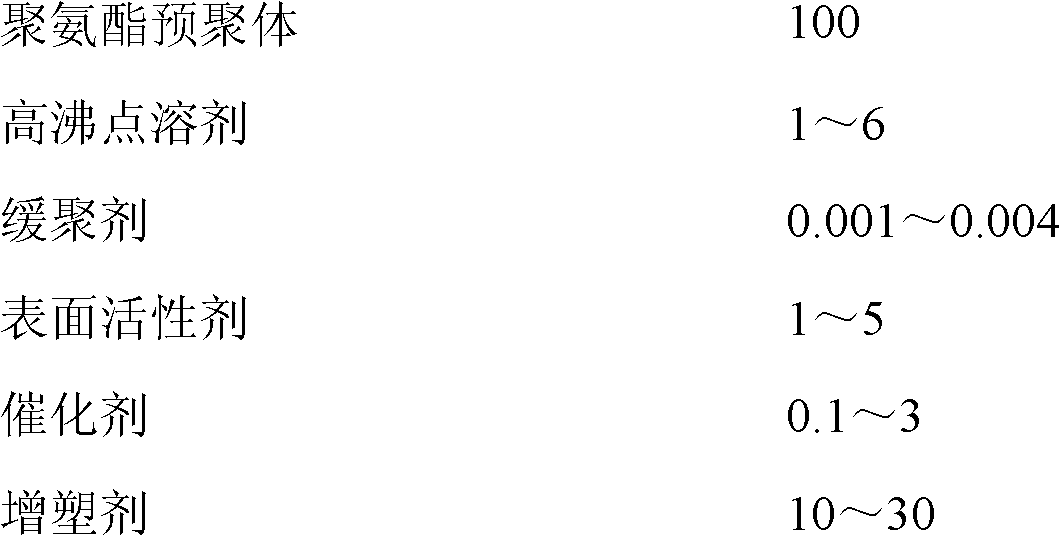

[0045] According to the method and steps of Example 1, prepare the environment-friendly hydrophobic polyurethane grouting material of the present invention according to the formula in Table 1

[0046] Table 1

[0047] Raw materials and product technical indicators

[0048] Viscosity at 25℃ mPa·s

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com