Combined type diamond drill bit under complex and difficult drilling conditions

A diamond drill bit and composite technology, which is used in drill bits, drilling equipment, earth-moving drilling, etc., can solve problems such as low energy utilization rate, wear, and drill bit failure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

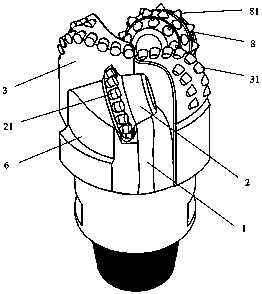

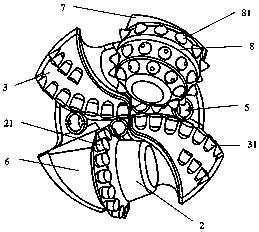

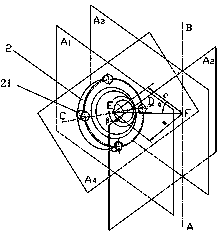

[0103] Such as figure 1 , 2 , 3, 4, and 5, a compound diamond drill bit for complex and difficult drilling conditions, including a drill body 1, a blade 3 extending from the drill body 1 or fixed on the drill body, water holes or nozzles 5, the The fixed blade 3 is provided with a fixed cutting element 31, and the drill bit is also provided with at least one cone body 8 and teeth 81, and at least one disk consisting of a disc cutter body 2 and a disc cutter cutting element 21. Knife, cone, disc cutter are formed to rotate and connect with bit body through cone support, disc cutter support respectively. Wherein, the cone support is the cone independent support 7, the disc cutter support is the disc cutter independent support 6, and the disc cutter cutting element 21 and the fixed cutting element 31 on the blade are circular PDC teeth.

[0104] The cutting teeth on the large deflection disc cutter form a long-distance spiral trajectory 210 at the bottom of the well, while the...

Embodiment 2

[0106] Such as Figure 6 , 7 , 14, 15, and 16, a compound diamond drill bit for complex and difficult drilling conditions, including a drill body 1, a blade 3 extending from the drill body 1 or fixed on the drill body, water holes or nozzles 5, the The fixed blade 3 is provided with a fixed cutting element 31, and the drill bit is also provided with at least one cone body 8 and teeth 81, and at least one disk consisting of a disc cutter body 2 and a disc cutter cutting element 21. Knife, toothed wheel, disc cutter form rotation connection with blade 3 respectively. In this example, both the disk cutter cutting element 21 and the fixed cutting element 31 on the blade 3 are circular PDC teeth.

[0107] The disc cutter teeth on the disc cutter and the cutting teeth on the fixed blade 3 are independent of each other, that is, the cutting teeth on the disc cutter do not replace the cutting teeth on the blade 3 in terms of structure, and will not directly affect the layout of the ...

Embodiment 3

[0111] Such as Figure 17 , 18 As shown, a composite diamond drill bit for complex and difficult drilling conditions includes a drill body 1, a blade 3 extending from the drill body 1 or fixed on the drill body, a water eye or a nozzle 5, and the fixed blade 3 is A fixed cutting element 31 is provided, and at least one cone body 8 and a tooth 81 are provided on the drill bit, and at least one disc cutter composed of a disc cutter body 2 and a disc cutter cutting element 21 is provided on the drill bit. The front side 33 is provided with a groove 20 that communicates with the cloth tooth surface 11, and the disc cutter is arranged in the groove 20. In this example, both the disk cutter cutting element 21 and the fixed cutting element 31 on the blade 3 are circular PDC teeth.

[0112] In the solution of the present invention, the cutting teeth on the disc cutter replace the fixed teeth on the blade 3 in structural form, and the alternate work of the cutting teeth in this area ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com