Reducing drilling rig

A drilling tool and drill bit technology, which is applied in the direction of drill bits, drilling equipment, earthwork drilling, etc., can solve problems such as broken blades, increased engineering costs, and weak structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the embodiments described in the accompanying drawings.

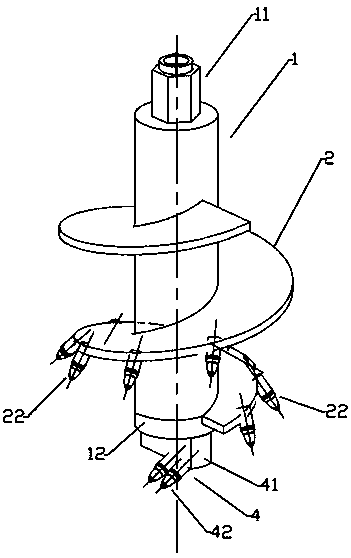

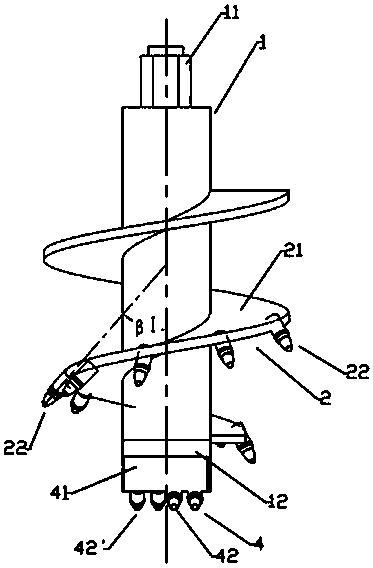

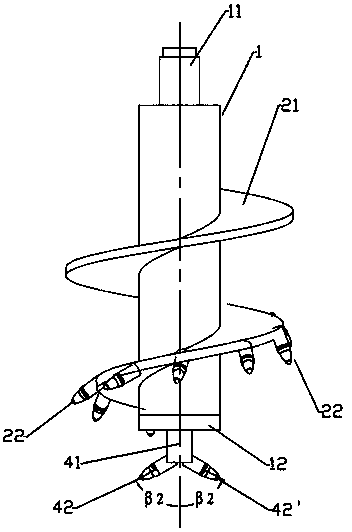

[0020] A variable diameter drilling tool, including a drill pipe 1 with a drill pipe body 10, a male joint 11 and a lower flange 12, a helical cutting wing 2 including fins 21 and several first picks 22, and a front end seat plate 41 And the front end drill bit 4 of two rows of second picks 42,42'; wherein:

[0021] The helical cutting wing 2 is radially arranged and fixed on the outer wall of the drilling tool body 10 through its fins 21. The fins 21 are helical fins with a conical lower part and a cylindrical upper part, and the outer diameter of the free end of the conical lower part is As the direction of rotation rises, it gradually increases, and its taper is 1:70 to 1:50; each of the first picks 22 in the plurality of first picks 22 is arranged at intervals and involute outwards around the fins The arc surface of the outer free end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com