Dry ice powder dynamic rock breaking device, dry ice powder dynamic rock breaking system and dry ice powder dynamic rock breaking method

A rock-breaking device and dry ice technology, applied in the field of expansion rock-breaking, can solve the problems of safety, impact and disturbance, etc., and achieve ideal rock-breaking effect, easy operation, and solve the problem of restricted dangerous chemicals.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

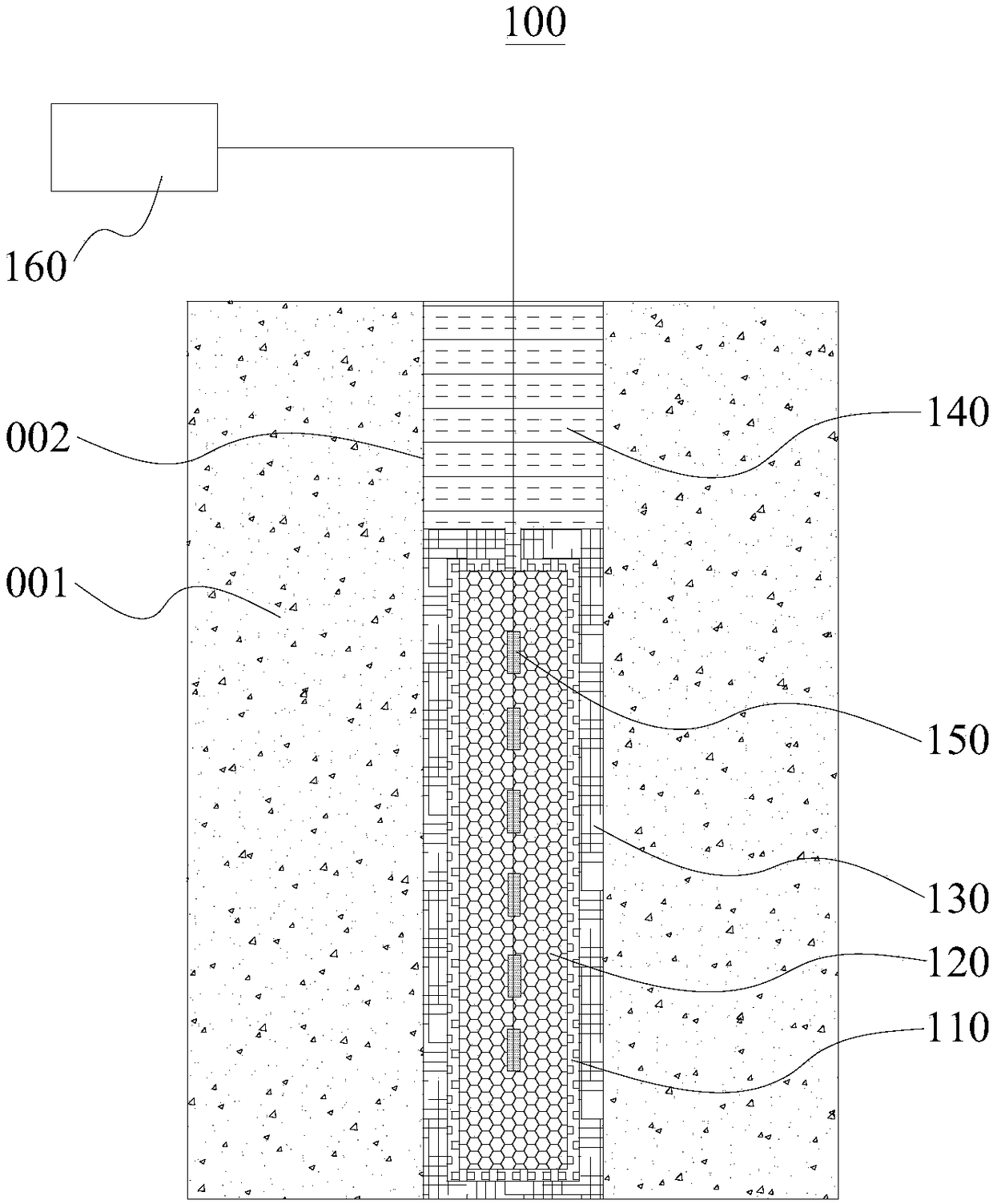

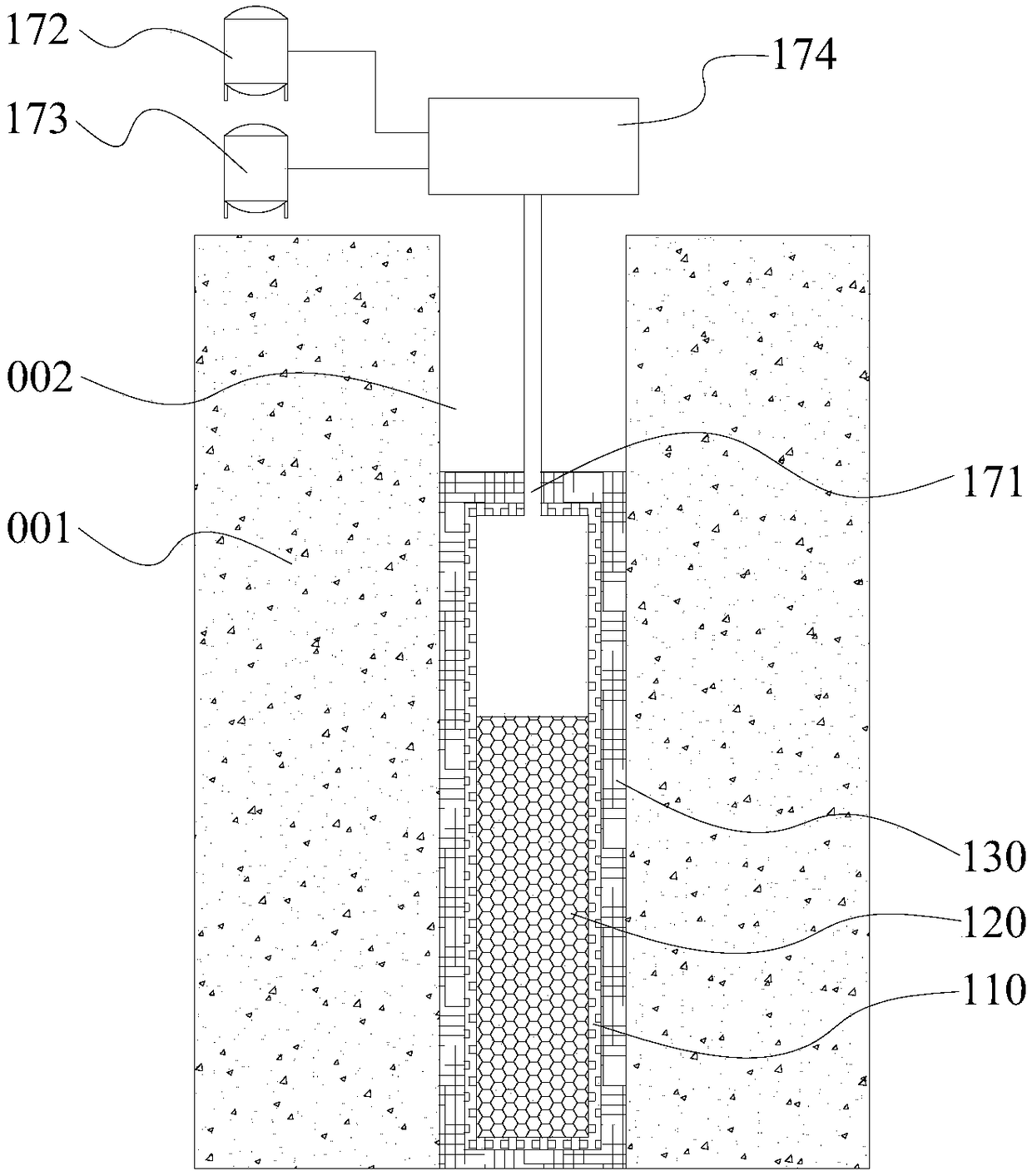

[0039] Please refer to figure 1 As shown, the present embodiment provides a dry ice powder dynamic rock-breaking device 100, which includes an energy concentrator disposed in the borehole 002 of the surrounding rock 001 of the formation, and a solidification material filled between the energy concentrator and the inner wall of the borehole 002. Layer 130, the energy concentrator includes an anti-seepage and heat-insulation shell 110 and a cracking agent 120 filled in the anti-seepage and heat-insulation shell 110, and the cracking agent 120 includes dry ice powder and CO 2 A mixture of energy-gathering agents, and a resistance wire trigger 150 is embedded in the anti-seepage and heat-insulating shell 110 . The borehole 002 in the present embodiment is vertically arranged, so the dry ice powder dynamic rock breaking device 100 in the borehole 002 is also vertically arranged, and the specific structure is: the energy concentrator is vertically arranged, and the solidified layer ...

no. 2 example

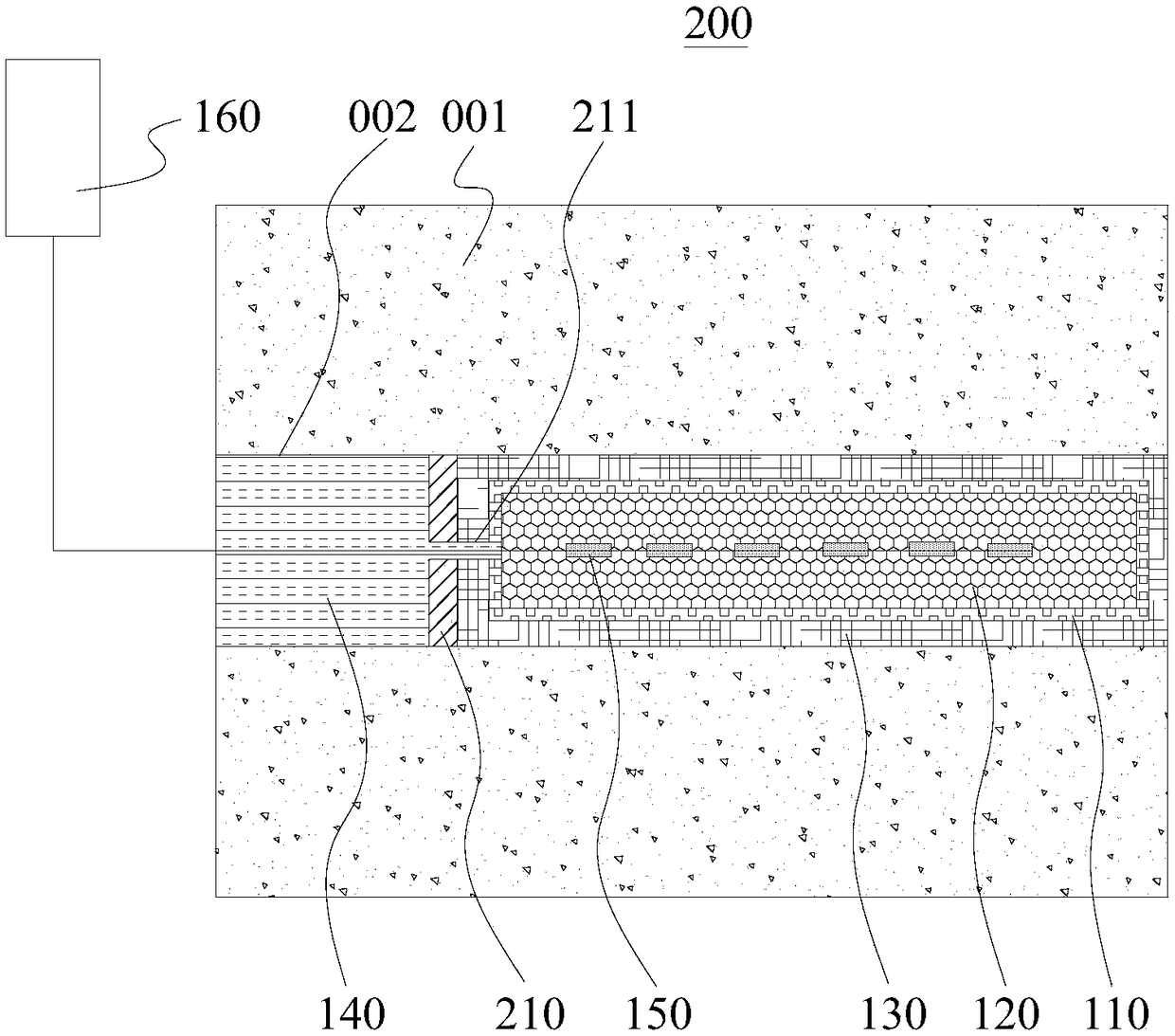

[0057] Please refer to image 3 As shown, the present embodiment provides a dry ice powder dynamic rock-breaking device 200, which includes an energy concentrator arranged in the borehole 002 of the surrounding rock 001 of the formation, and a solidification material filled between the energy concentrator and the inner wall of the borehole 002. Layer 130, the energy concentrator includes an anti-seepage and heat-insulation shell 110 and a cracking agent 120 filled in the anti-seepage and heat-insulation shell 110, and the cracking agent 120 includes dry ice powder and CO 2 A mixture of energy-gathering agents, and a resistance wire trigger 150 is embedded in the anti-seepage and heat-insulating shell 110 . The borehole 002 in this embodiment is arranged horizontally, so the dry ice powder dynamic rock-breaking device 200 in the borehole 002 is also arranged horizontally, and the specific structure is: the energy collector is arranged horizontally, and the solidified layer 130 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com