Vehicle roll center position measuring device and calculating method of vehicle roll center position

A center position and measuring device technology, which is applied in the research field of vehicle rollover and rollover, can solve the problems affecting the accuracy and effect of the vehicle anti-rollover control system, and achieve the effect of improving the research accuracy and effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

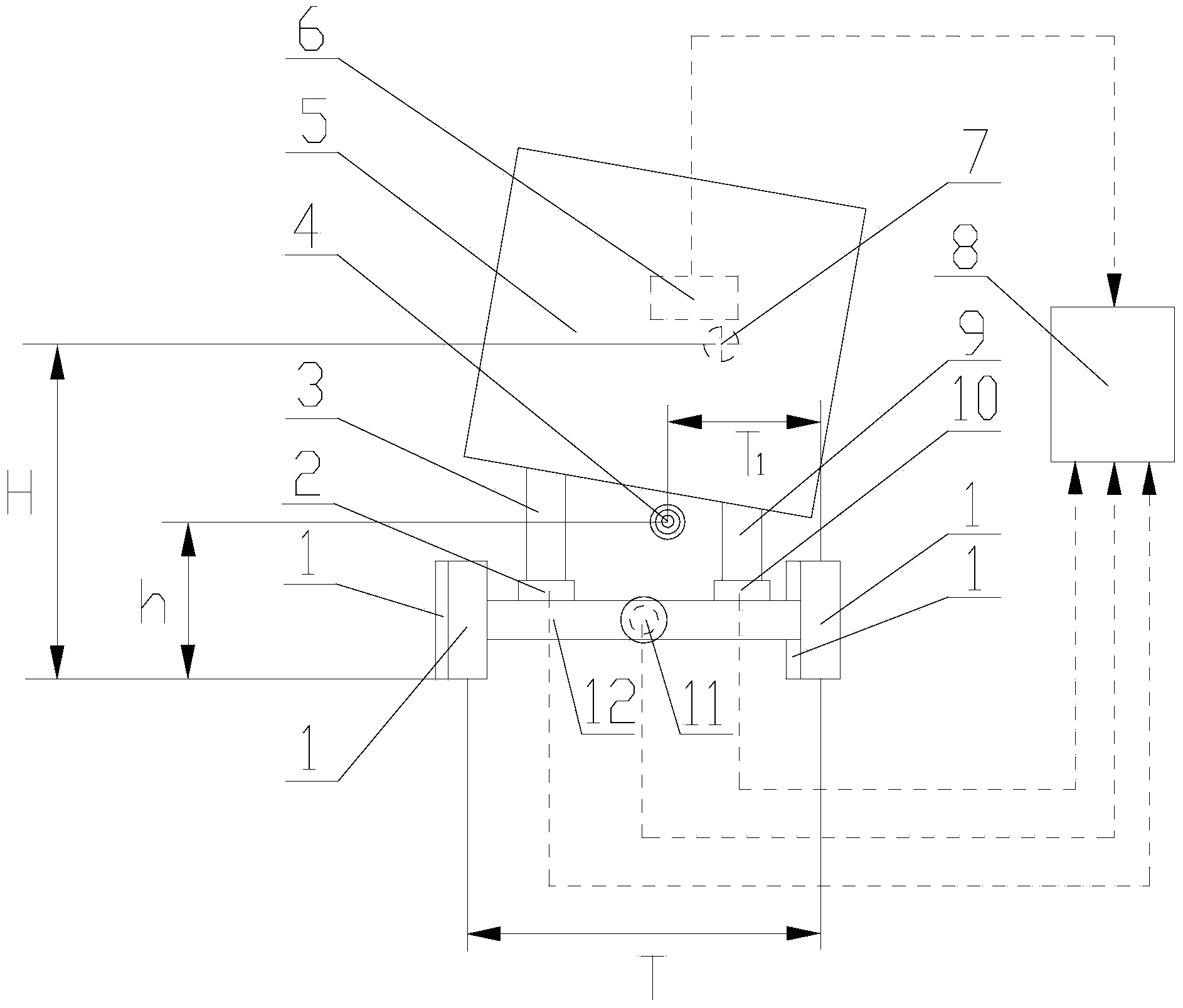

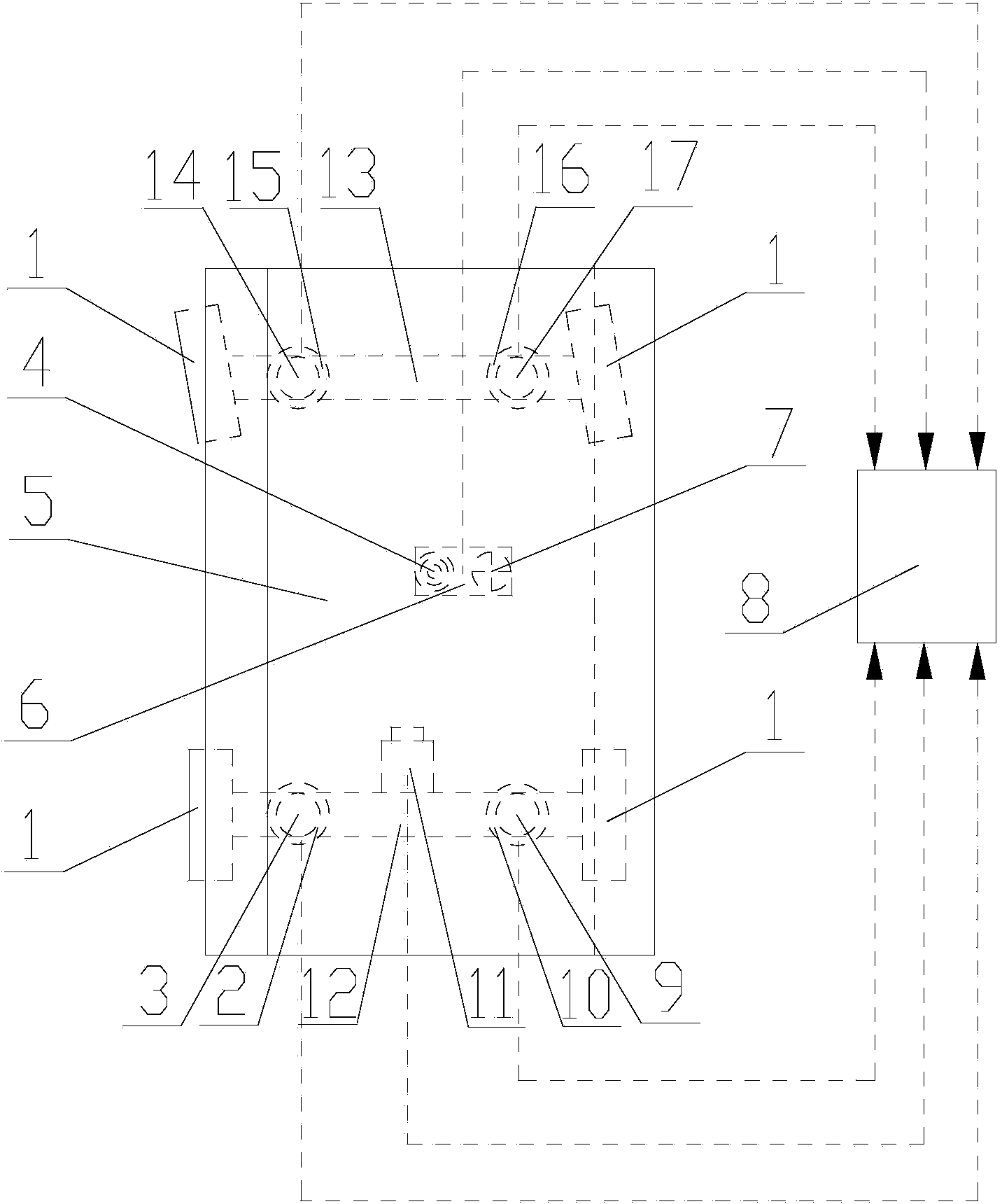

[0014] Such as figure 1 , figure 2 The vehicle roll center position measuring device shown includes a wheel 1, a left rear wheel vertical load sensor 2, a left rear suspension 3, a vehicle body 5, a center of mass sensing unit 6, a calculation unit 8, and a right rear suspension 9 , right rear wheel vertical load sensor 10, vehicle speed sensor 11, rear axle 12, front axle 13, left front suspension 14, left front wheel vertical load sensor 15, right front wheel vertical load sensor 16, right front suspension 17; The center of mass sensing unit 6 includes a lateral acceleration sensor, a yaw rate sensor and a roll angle sensor, and is fixedly installed on the vehicle body 5 at the center of mass of the vehicle; the two ends of the rear axle 12 and the front axle 13 are connected to the wheels 1; The upper end of the rear suspension 3 is fixedly connected with the vehicle body 5, and the lower end of the left rear suspension 3 is fixedly installed on the rear axle 12 thro...

Embodiment 2

[0016] This embodiment provides a method for calculating the center position of the vehicle roll. When the vehicle is in the process of rolling, the center of mass sensing unit 6 can measure the lateral acceleration, yaw rate, roll angular acceleration and roll angle at the center of mass of the vehicle. Vehicle speed sensor 11 can measure the running speed of automobile, and left rear wheel vertical load sensor 2, right rear wheel vertical load sensor 10, left front wheel vertical load sensor 15, right front wheel vertical load sensor 16 can measure the load that each wheel is subjected to. Vertical load, calculation unit 8 according to the formula Calculate the vertical distance h from the vehicle roll center to the center of mass, according to the formula Deduce the horizontal distance T from the center of the vehicle roll to the center of the right wheel 1 , where g is the acceleration of gravity, T is the horizontal distance between the wheels on both sides of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com