Torsion girder-like rear suspension

A technology of torsion beam suspension and torsion beam, which is applied in the direction of suspension, elastic suspension, transportation and packaging, etc., and can solve the problem of large body roll angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

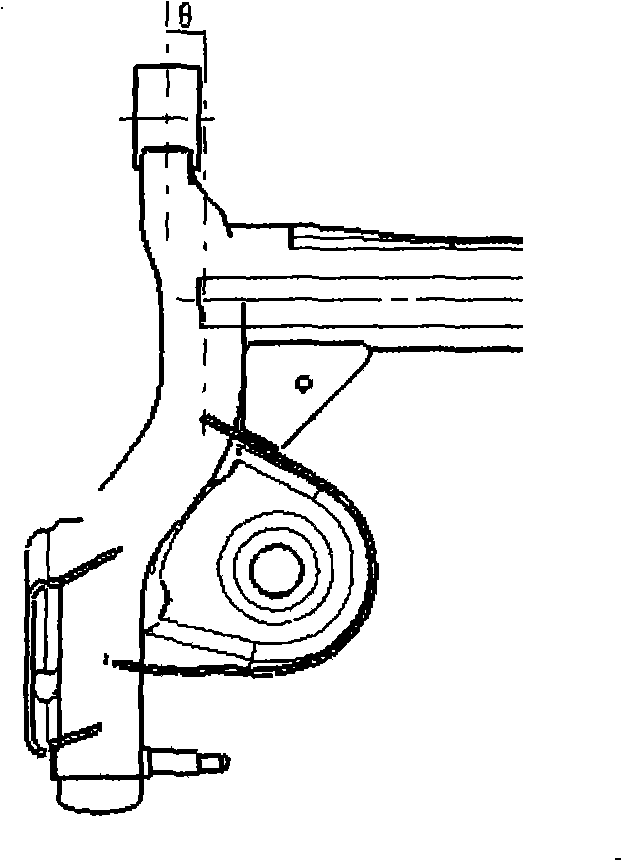

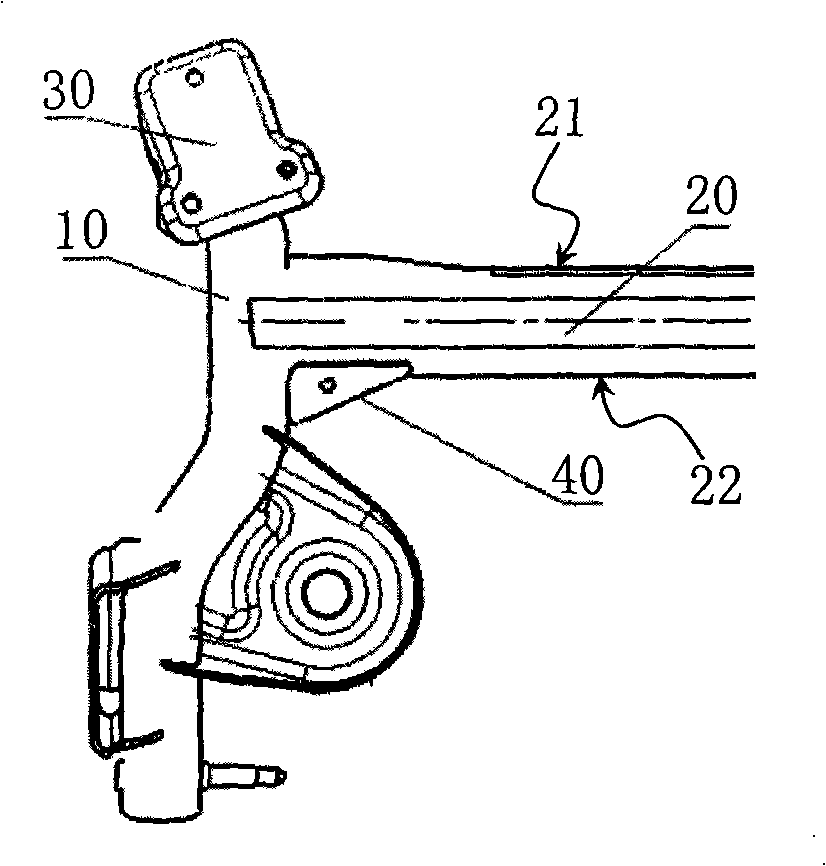

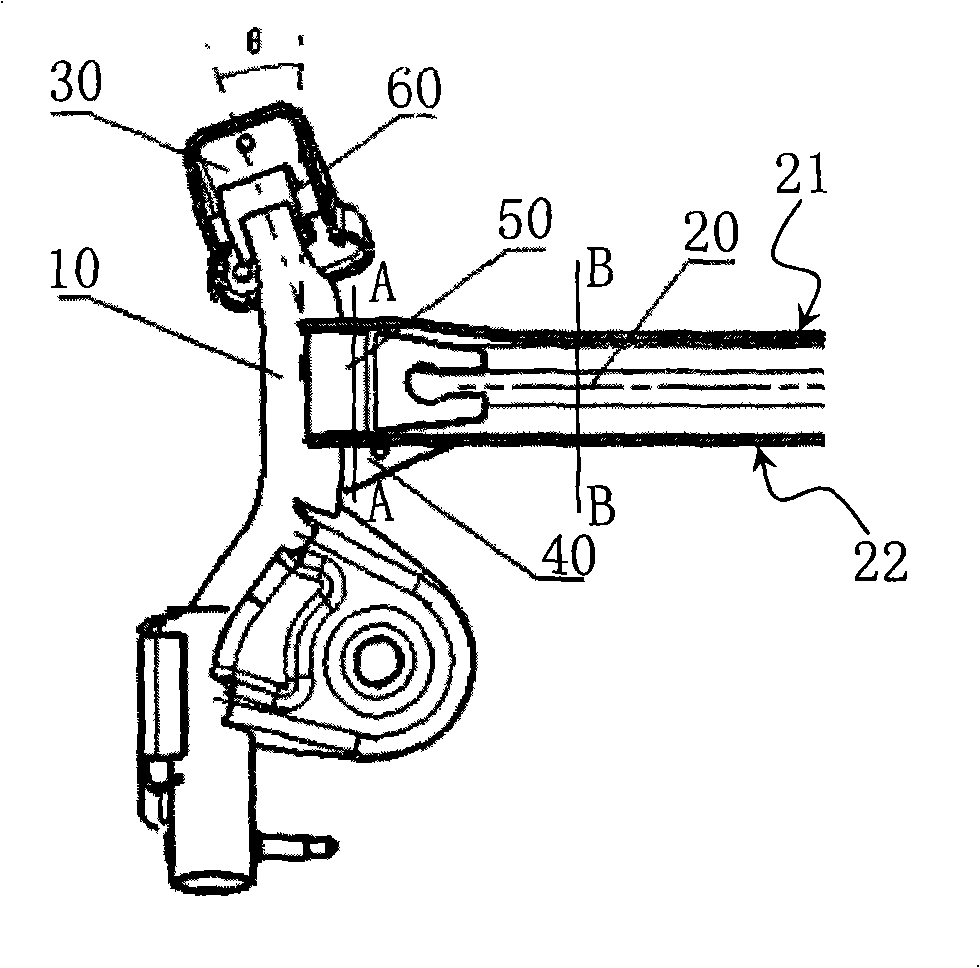

[0012] Twisted beam suspension, the left and right suspension trailing arms 10 composed of pipe fittings are arranged on both sides along the front and rear direction of the vehicle, and a torsion beam body 20 with a trough-shaped cross section is connected between them, and the torsion beam body 20 is a trough-shaped rod , the opening of which is arranged downwards.

[0013] The front ends of the left and right suspension trailing arms 10 connected to the torsion beam body 20 are in a flared shape at the connecting parts. This improved design has a significant inhibitory effect on the transition of the rear axle when the vehicle is turning.

[0014] Rib plates 40 and 50 are provided at the rear and lower parts of the joints of the torsion beam body 20 and the left and right suspension trailing arms 10 .

[0015] The cross-section of the torsion beam body 20 is generally V-shaped, so that good shear resistance can be obtained, such as Figure 4 shown.

[0016] The cross-sect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com