Method for preparing embedded material and embedded material prepared thereby

A manufacturing method and technology of supporting materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

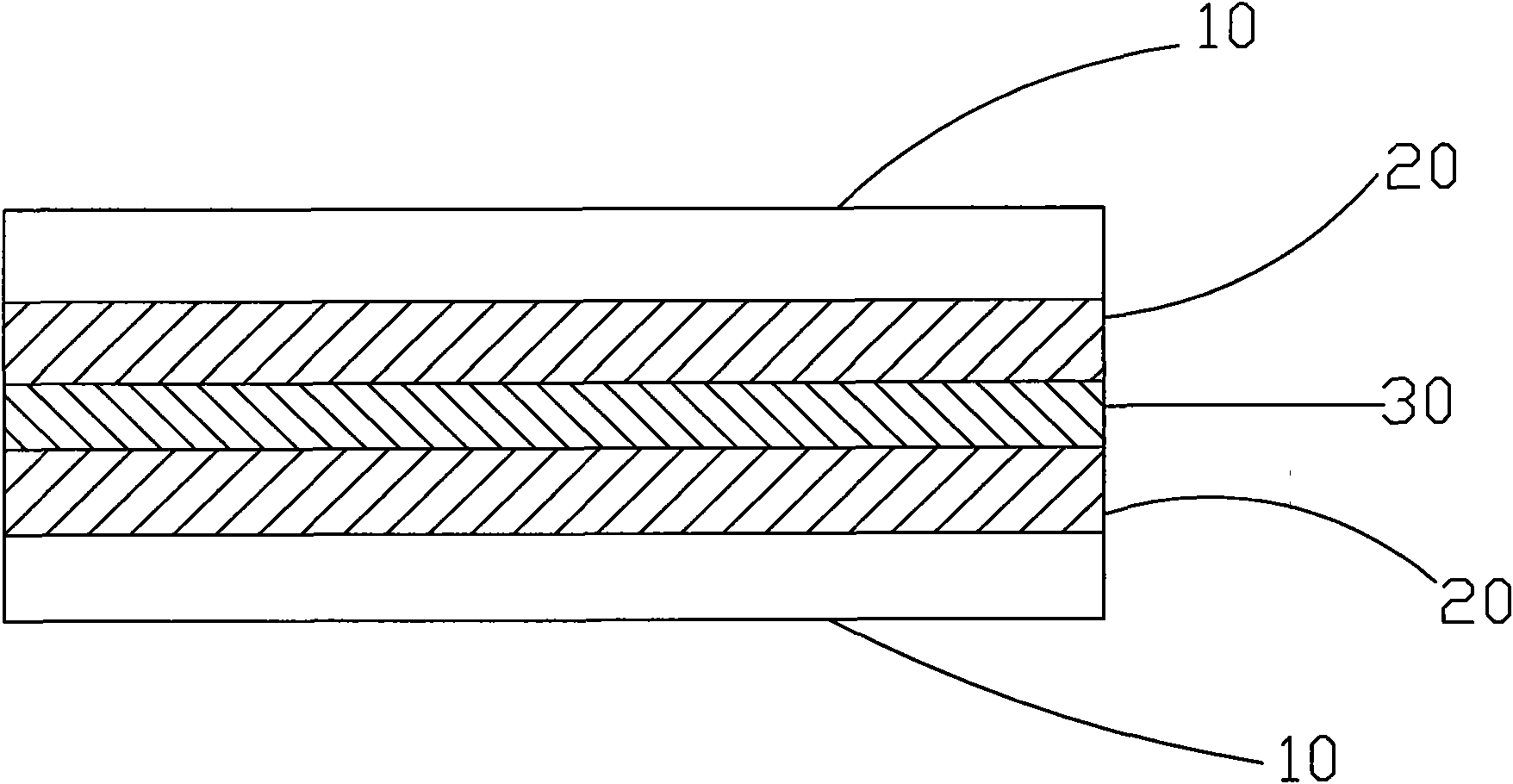

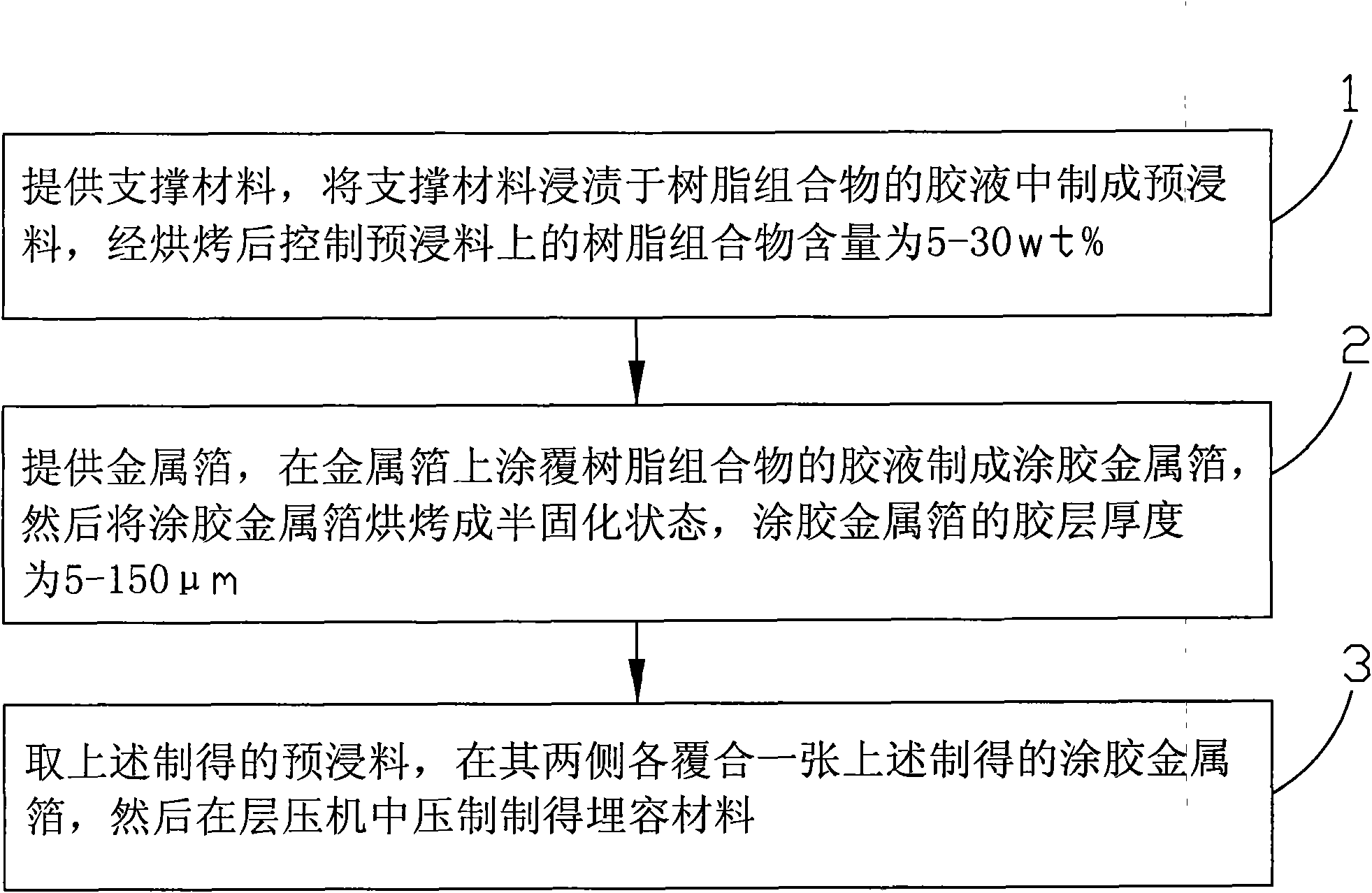

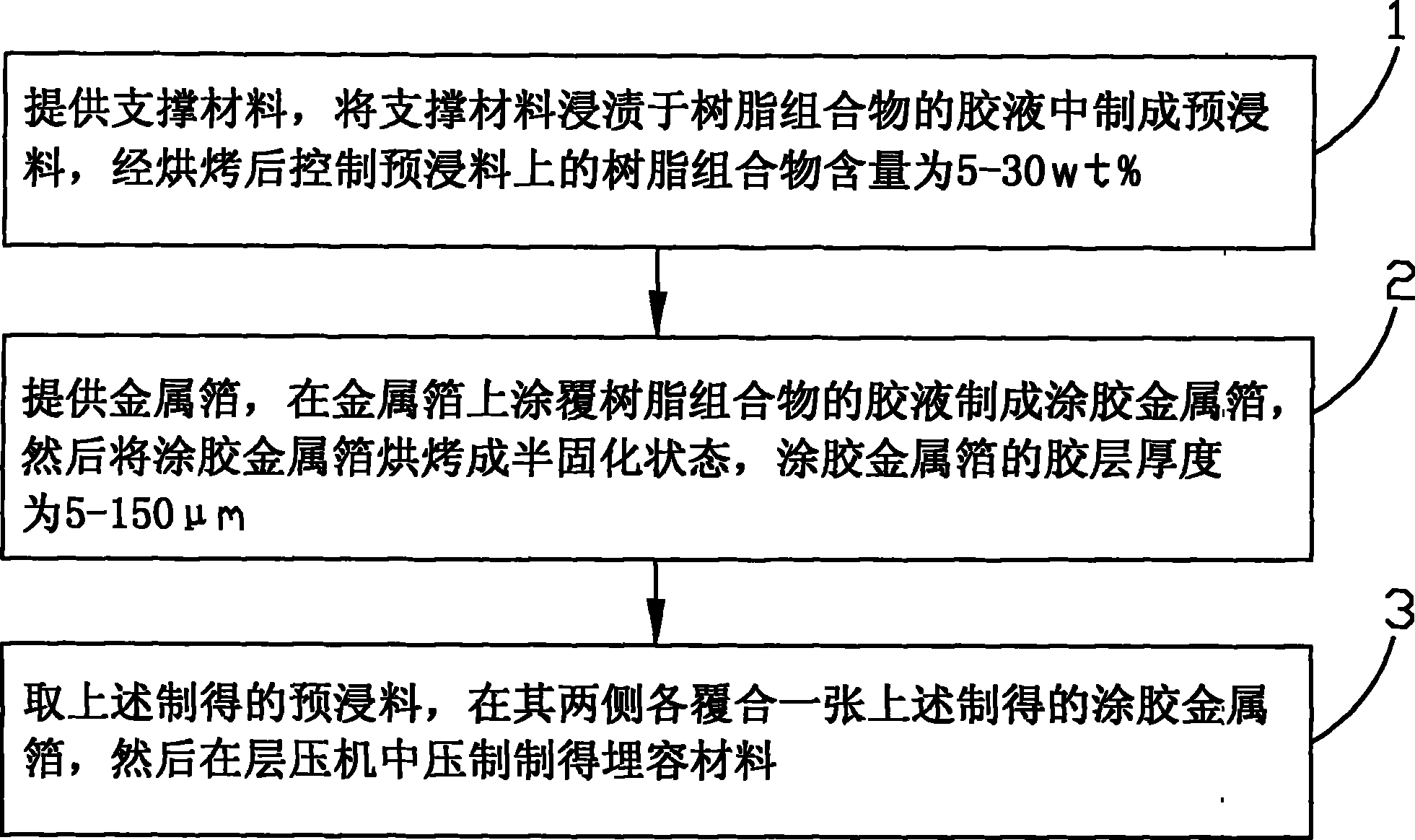

[0025] The preparation method of embedding material of the present invention, it comprises the following steps:

[0026] Step 1. Provide a support material, immerse the support material in the glue solution of the resin composition with a small solid content, and control the content of the resin composition on the prepreg to 5-30 wt% after baking. Wherein the support material can be inorganic or organic material. The inorganic material may be a woven or non-woven fabric or paper of glass fiber, carbon fiber, boron fiber, metal, or the like. The glass fiber cloth or non-woven fabric can be E-glass, Q-type cloth, NE cloth, D-type cloth, S-type cloth, high silica cloth, etc. The organic material is woven or non-woven fabric or paper made of polyester, polyamine, polyacrylic acid, polyimide, aramid, polytetrafluoroethylene, syndiotactic polystyrene, etc. However, the support material is not limited thereto. Among them, E-glass fiberglass material is preferred as the support mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com