Plasma processing apparatus

a processing apparatus and plasma technology, applied in the field of high frequency antennas, can solve the problems of deteriorating plasma process uniformity more difficult to achieve plasma uniformity, so as to improve the uniformity of plasma density and plasma processing characteristics in the target object surfa

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

Overall Configuration of Plasma Processing Apparatus

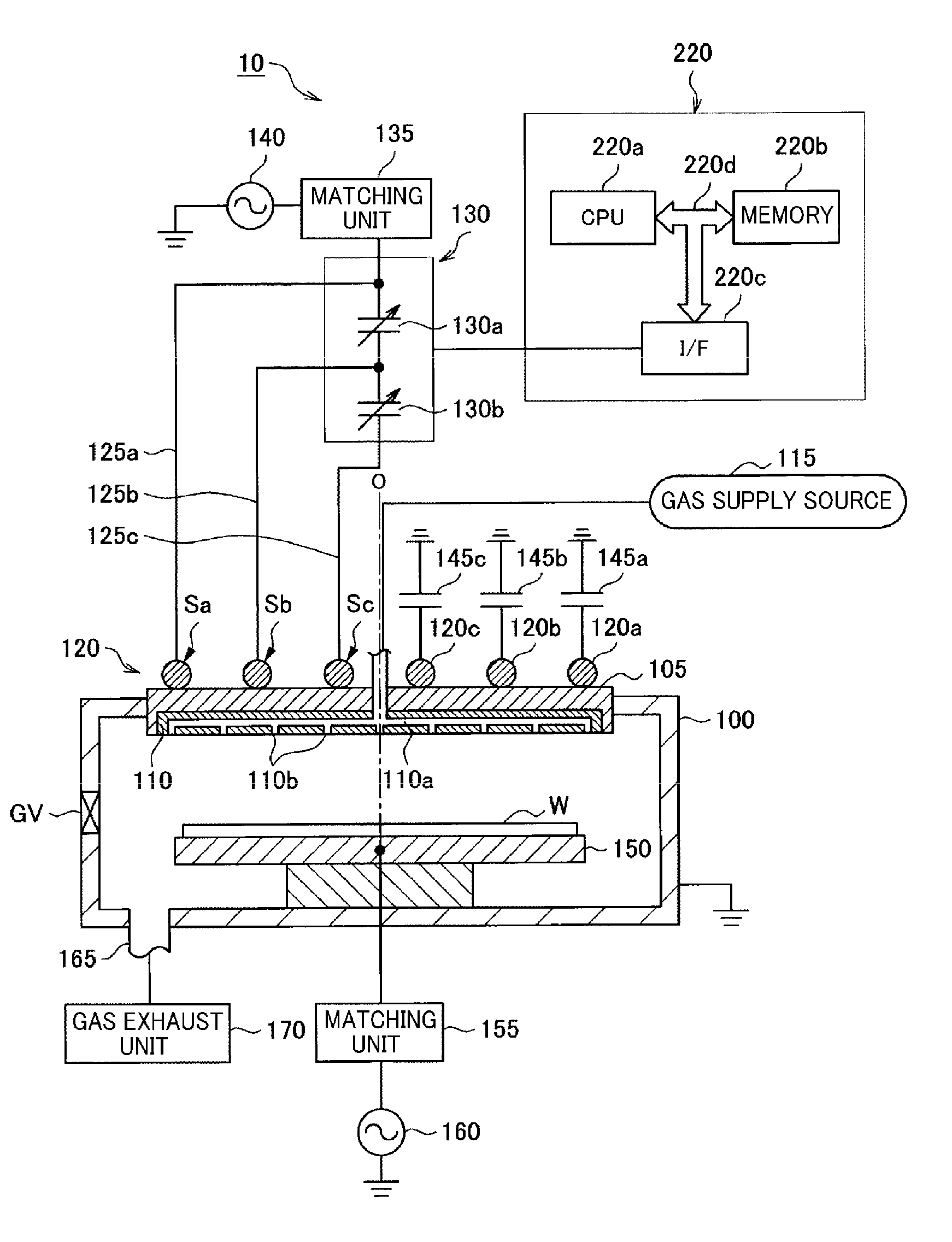

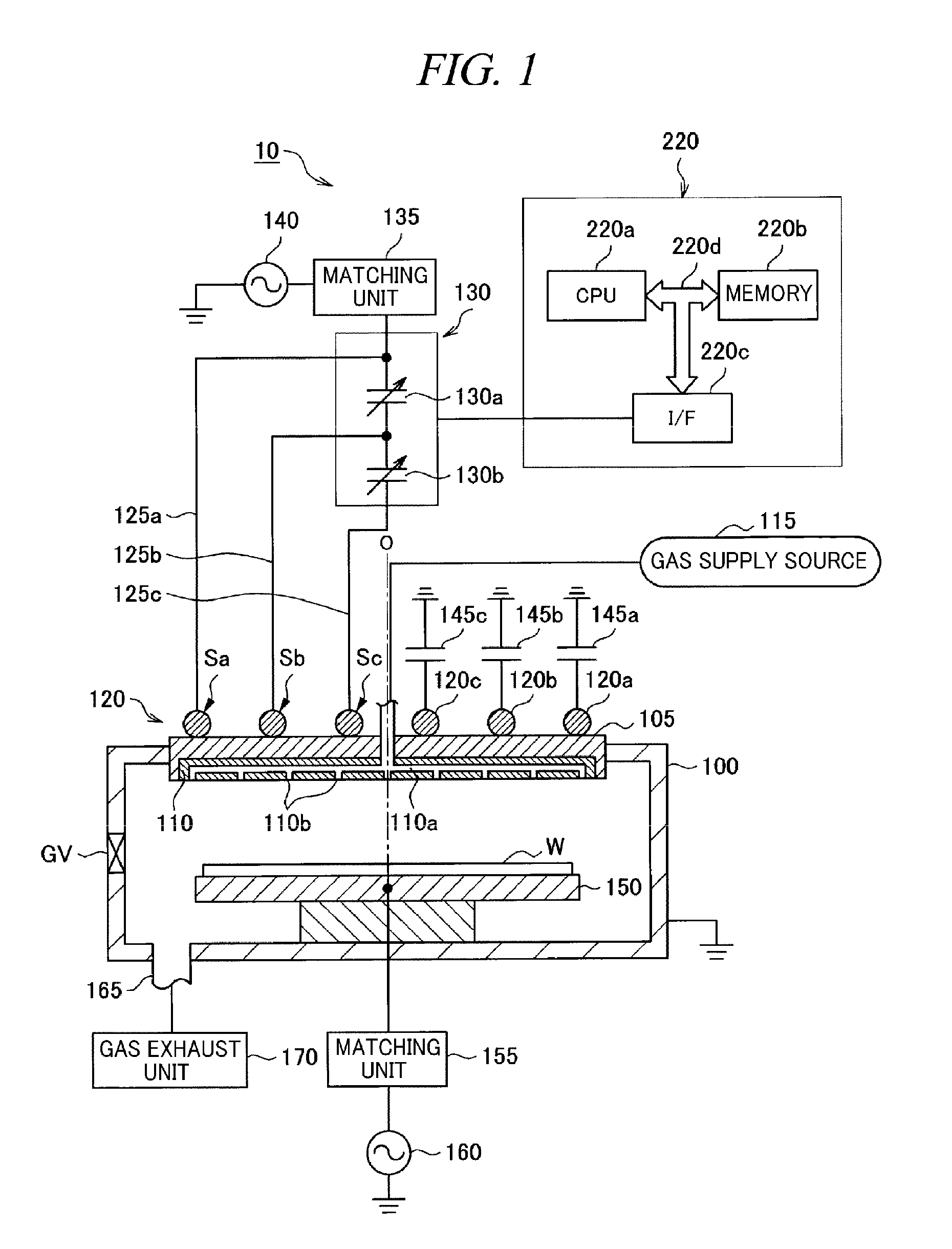

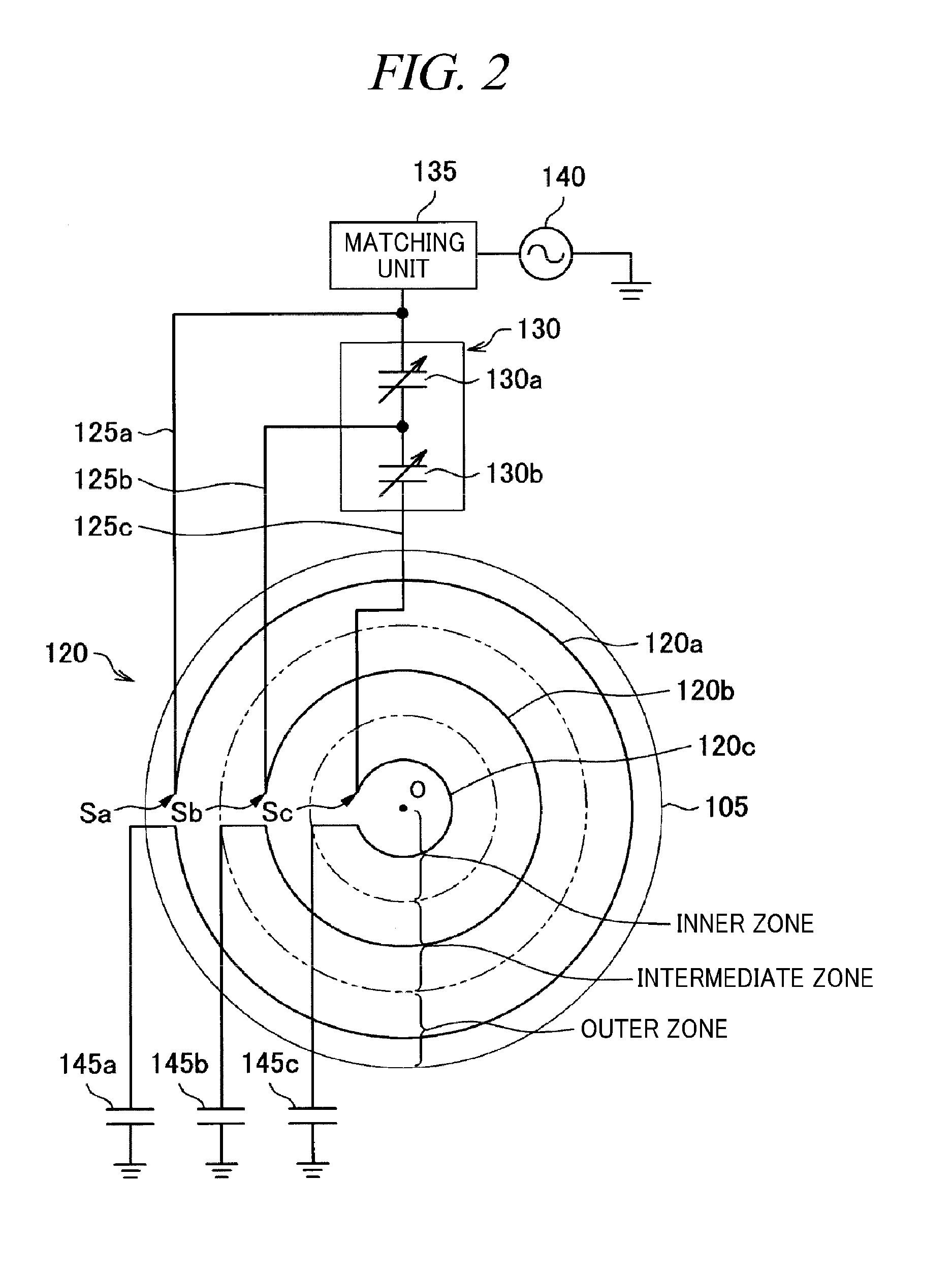

[0045]Referring to FIGS. 1 and 2, an overall configuration of a plasma processing apparatus in accordance with a first embodiment of the present disclosure will be explained. FIG. 1 is a schematic longitudinal cross sectional view of an inductively coupled plasma processing apparatus, and FIG. 2 is a diagram illustrating a configuration of a high frequency antenna.

[0046]As shown in FIG. 1, a plasma processing apparatus 10 such as an etching apparatus includes a processing chamber 100 for plasma-processing a wafer W which is loaded through a gate valve GV. The processing chamber 100 having a cylindrical shape is made of metal such as aluminum, and is grounded. An inner wall of the processing chamber 100 is anodically oxidized. Further, the inner wall of the processing chamber 100 may be covered with a dielectric material such as quartz, yttria, or the like.

[0047]A dielectric window 105 is fitted into an opening of the processing cha...

modification examples

of the First Embodiment

[0081]Modification examples of the first embodiment are illustrated in FIGS. 5 to 7. Although the inside configuration of a processing chamber 100 is not illustrated in each plasma processing apparatus 10 shown in FIGS. 5 to 7, the inside configuration of the processing chamber 100 is the same as shown in FIG. 1. In a plasma processing apparatus 10 of FIG. 5, a power feed point Sc of an inner coil 120c is deviated about 180° from power feed points Sa and Sb of an outer coil 120a and an intermediate coil 120b, respectively. In a plasma processing apparatus 10 of FIG. 6, power feed points Sb and Sc of an intermediate coil 120b and an inner coil 120c are deviated about 180° from a power feed point Sa of an outer coil 120a.

[0082]In a plasma processing apparatus 10 of FIG. 7, a power feed point Sc of an inner coil 120c is deviated about 180° from power feed points Sa and Sb of an outer coil 120a and an intermediate coil 120b, respectively. Here, the variable imped...

second embodiment

[0084]Generally, in the inductively coupled plasma processing apparatus, not only (1) the generation of the plasma by acceleration of electrons using the electromagnetic field energy from the high frequency antenna 120 needs to be considered, but (2) plasma uniformity also needs to be achieved in consideration of electrons coupled to the plasma by a capacitor. Thus, the apparatus needs to be designed in consideration of not only an antenna design for (1) but also a capacitive component for (2).

[0085]In the plasma processing apparatus 10 in accordance with the first embodiment, uniformity of a plasma density in a diametric direction of the wafer W can be achieved. That is, in the first embodiment, the high frequency antenna 120 is divided into the three imaginary zones, i.e., the outer zone, the inner zone and the intermediate zone, and the above-mentioned coils are installed in the respective zones in consideration of (1), so that the uniformity of the plasma density in the diametri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| frequency | aaaaa | aaaaa |

| frequency | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com