Self-purifying device for exhaust port of single-crystal furnace

A self-purification, single crystal furnace technology, applied in post-processing devices, crystal growth, chemical instruments and methods, etc., can solve the problems of exhaust system paralysis, affecting the crystallization effect and quality, etc., to improve the quality and structure of single crystals Simple and efficient cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

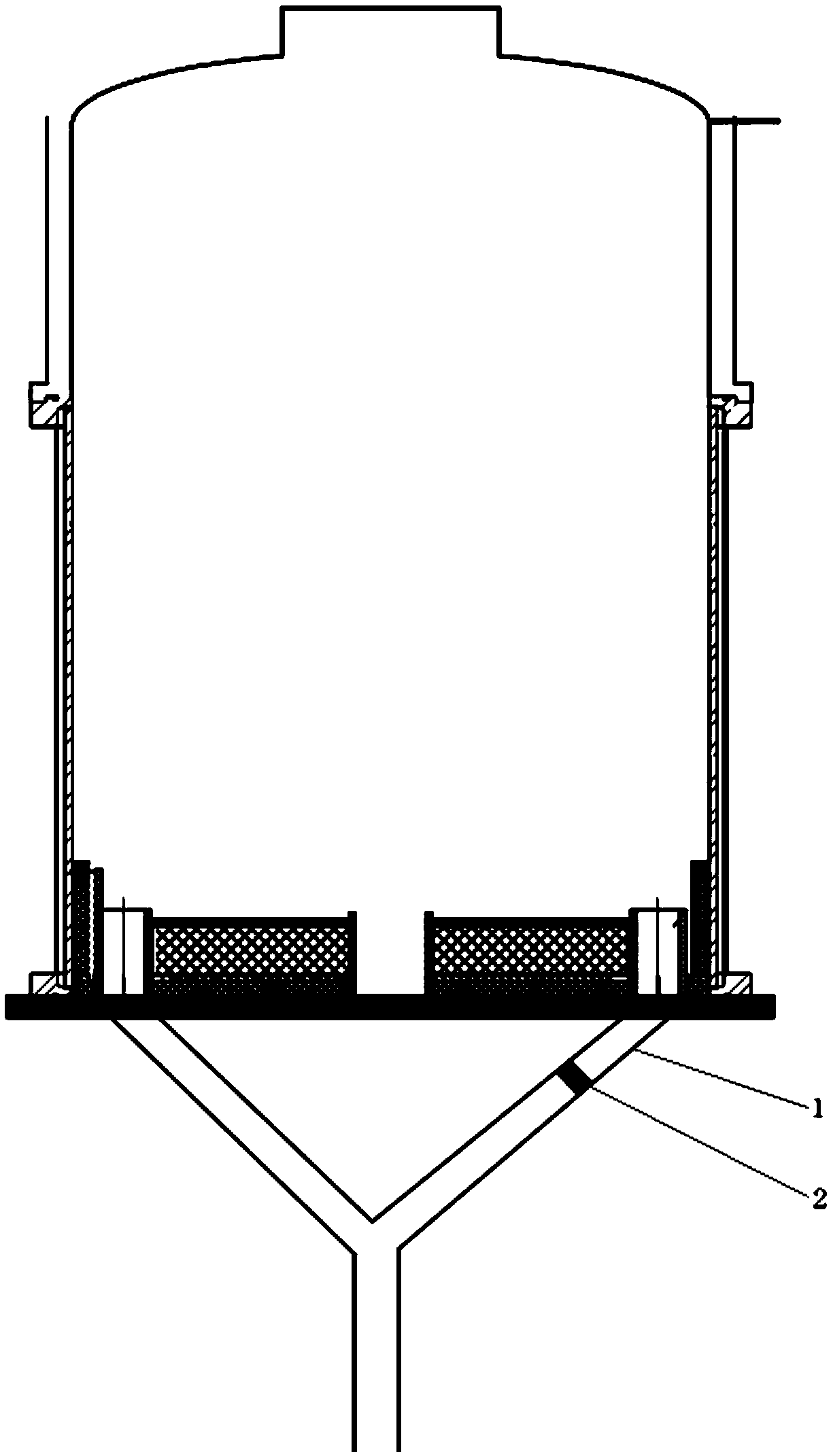

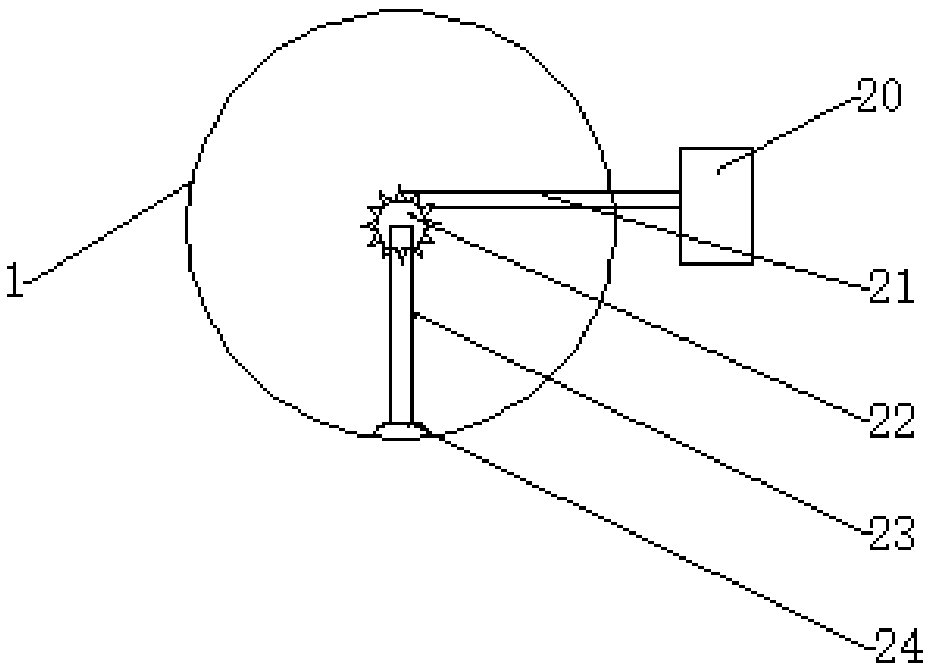

[0020] figure 1 and 2 The structure of an embodiment of the present invention is shown, and the structure of this implementation is specifically shown. This embodiment relates to a self-purifying device for the exhaust port of a single crystal furnace. The self-purifying device for the exhaust port of a single crystal furnace is installed on the In the exhaust pipe of the furnace, it is located in the place where oxides accumulate. Clean up the oxides that are continuously deposited during the operation of the furnace body to prevent excessive accumulation of oxides from blocking the exhaust pipe, improve the efficiency of Czochralski single crystal, and improve the single crystal. crystal quality.

[0021] The above-mentioned self-purifying device for the exhaust port of the single crystal furnace, such as figure 1 and 2 As shown, it inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com