Boron nitride pyrolyzing crucible coating method

A crucible and surface technology, applied in the field of PBN crucible surface treatment, can solve the problems of increasing industrial production cost, layering, and not being able to solve the service life of PBN crucible well

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

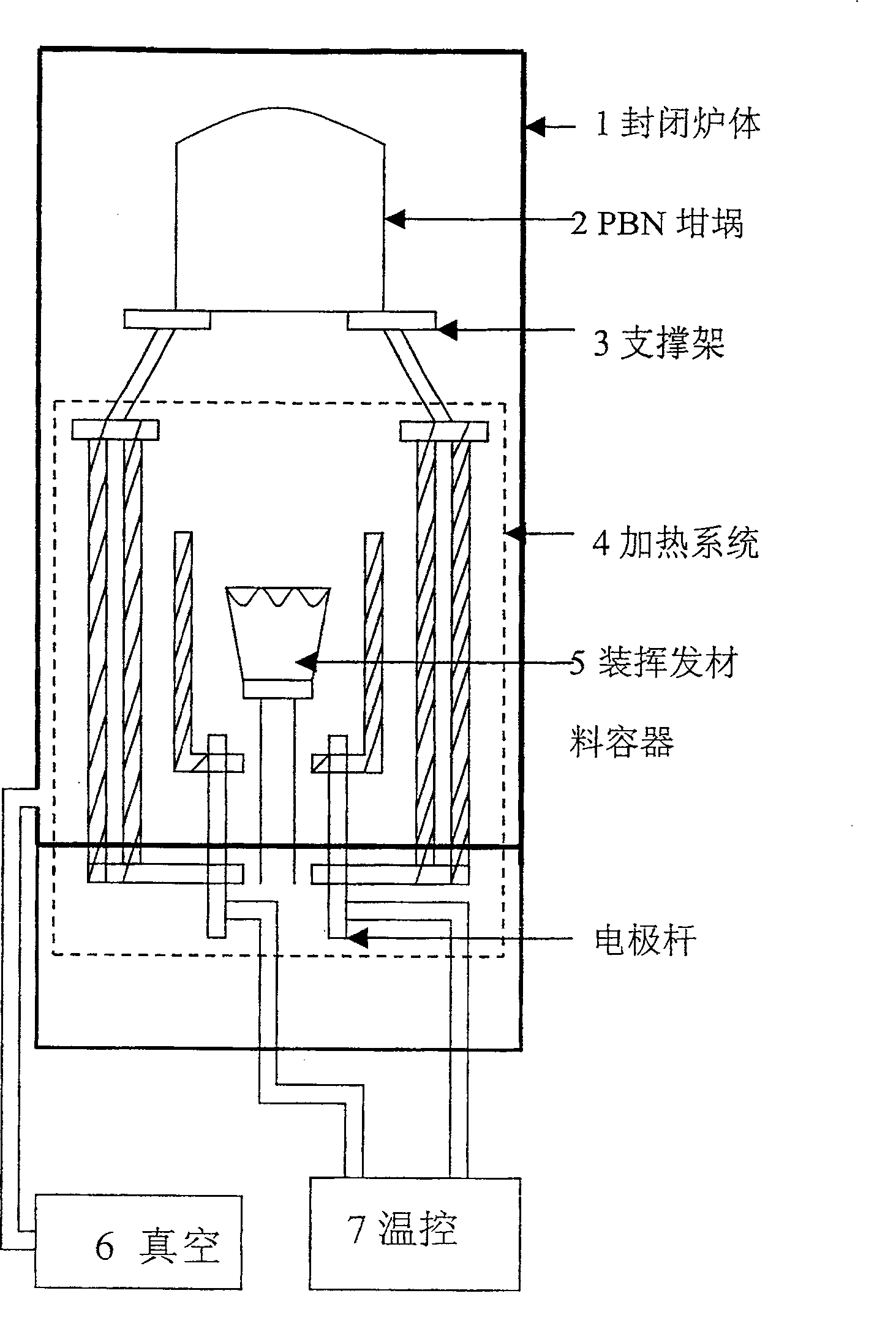

[0020] see figure 1 Shown, the PBN crucible surface coating of the present invention comprises:

[0021] 1. Equipment

[0022] The container (5) for containing the volatile material is located in the center of the closed furnace chamber (1), and is made of high temperature resistant material, which does not react with the volatile material. Volatile materials can form a thin film on the surface of the PBN(2) crucible without affecting the quality of the bulk single crystal. The PBN (2) crucible is on the support system (3) at the top of the closed furnace chamber (1).

[0023] A set of heating system (4) and temperature control equipment (7) are used to heat up the temperature, so that the volatile material is diffused to the surface layer of the PBN crucible for deposition. The heating system (4) is around the closed furnace chamber (1).

[0024] A support system (3) supports the PBN crucible (2) and requires high temperature resistance.

[0025] A closed furnace chamber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com