A method for directly epitaxially growing germanium dummy substrate on silicon substrate

An epitaxial growth, silicon substrate technology, applied in electrical components, circuits, semiconductor/solid-state device manufacturing, etc., can solve the problems of unfavorable III-V heterostructure growth, large surface roughness of epitaxial layers, and dislocation density of epitaxial layers. Advanced problems, to achieve the effect of high single crystal quality, low cost and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

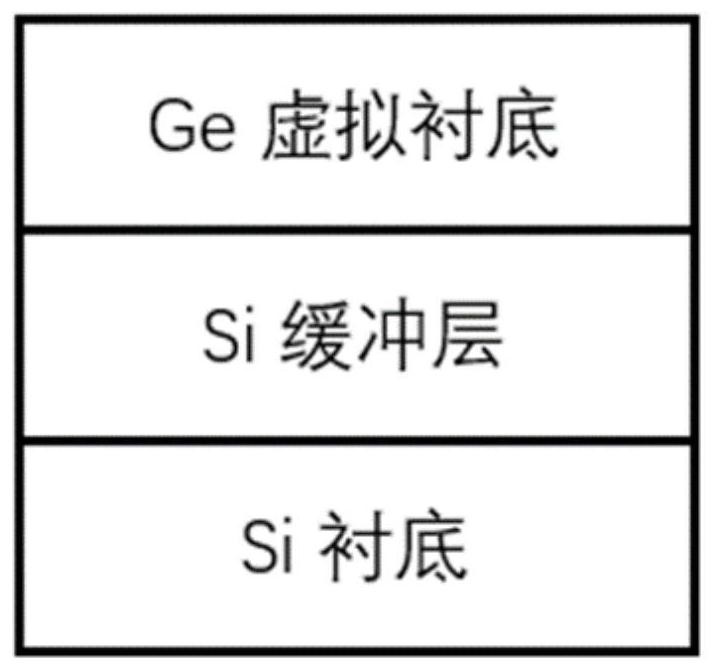

[0032] The invention provides a method for directly epitaxially growing a dummy germanium substrate on a silicon substrate through molecular beam epitaxy. figure 1 It is a structural schematic diagram of the germanium dummy substrate of the present embodiment, and the specific preparation method is as follows:

[0033] Through solid-state source molecular beam epitaxy, the (100) and (111) crystal plane silicon substrates are first surface treated. The silicon substrate treated with hydrofluoric acid is introduced into the vacuum chamber, and the substrate is kept rotating. For the silicon (100) substrate, the substrate heater is raised to 500-600° C. and kept for 5-10 minutes; for the silicon ( 111) Substrate, raising the substrate heater to 800-1000° C. and maintaining it for 5-10 minutes.

[0034] Then a silicon buffer layer with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com