Band gap modified ge PMOS device and its preparation method

A device and modification technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as unfavorable alloy growth, and achieve the effects of improving current drive and frequency characteristics, low process difficulty, and simple preparation technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

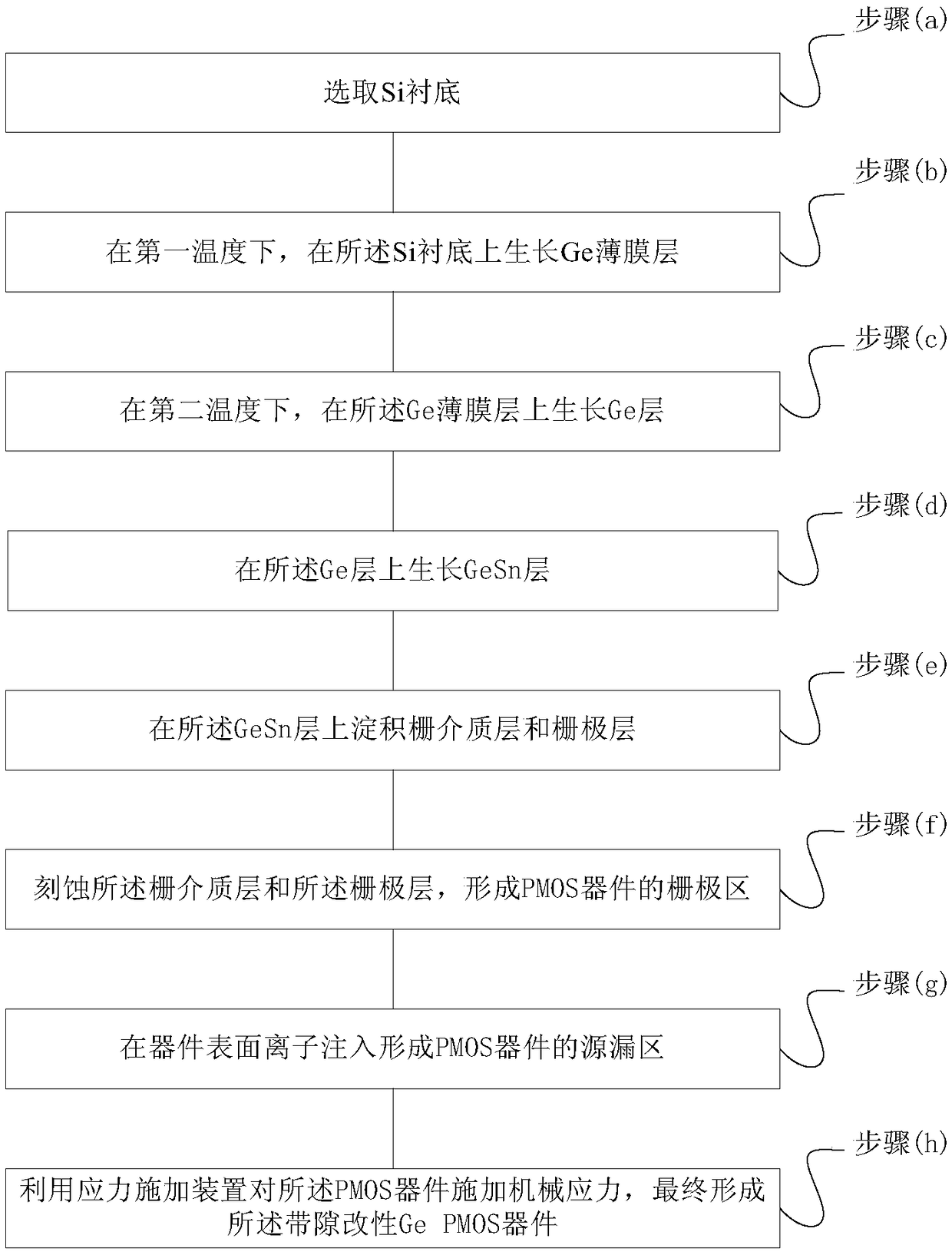

[0062] See figure 2 , figure 2 A flow chart of a method for preparing a direct bandgap Ge PMOS device provided by an embodiment of the present invention; the method includes the following steps:

[0063] Step a, select Si substrate;

[0064] Step b, growing a Ge thin film layer on the Si substrate at a first temperature;

[0065] Step c, growing a Ge layer on the Ge thin film layer at a second temperature;

[0066] Step d, growing a GeSn layer on the Ge layer;

[0067] Step e, depositing a gate dielectric layer and a gate layer on the GeSn layer;

[0068] Step f, etching the gate dielectric layer and the gate layer to form the gate region of the PMOS device;

[0069] Step g, forming source and drain regions of the PMOS device by ion implantation on the device surface;

[0070] Step h, using a stress applying device to apply mechanical stress to the PMOS device to finally form the bandgap modified Ge PMOS device.

[0071] Wherein, in step b and step c, the first temper...

Embodiment 2

[0089] See Figure 4a-Figure 4j , Figure 4a-Figure 4j It is a schematic diagram of a method for fabricating a direct bandgap Ge PMOS device provided by an embodiment of the present invention. On the basis of the above embodiments, this embodiment will introduce the process flow of the present invention in more detail. The method includes:

[0090] S101. Substrate selection. Such as Figure 4a As shown, the Si substrate sheet 201 whose crystal orientation is (001) is selected as the original material;

[0091] S102. Using the method of molecular beam epitaxy (MBE), on the Si substrate 201, grow an n-type Ge film with a crystal orientation of (001) on the Si substrate 201 by a two-step method of low temperature and high temperature, and the doping concentration is 1×10 16 ~5×10 16 cm -3 . specifically:

[0092] S1021, such as Figure 4b As shown, a 50 nm thick "low temperature" Ge ((LT-Ge) film 202 was grown at 275 ~ 325 °C. Most of the relaxation of elastic stress occur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com