Multi-diffusion manufacturing method for polycrystalline silicon wafer

A technology of multiple diffusion and manufacturing methods, which is applied in the directions of diffusion/doping, final product manufacturing, chemical instruments and methods, etc., and can solve the problems such as the difficulty of distinguishing the colors of the front and back sides

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

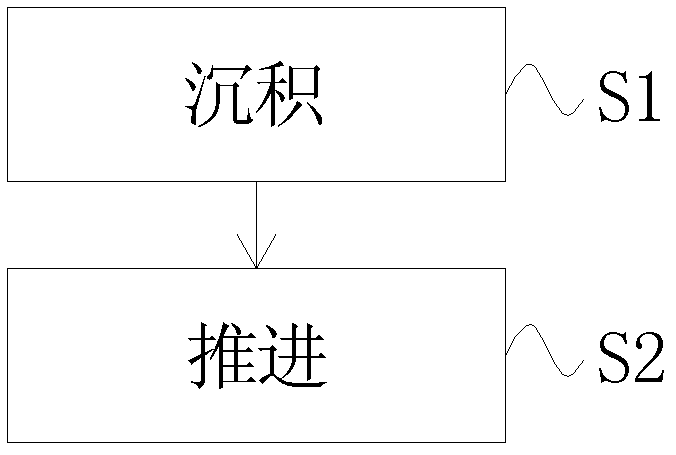

[0032] The core of the present invention is to provide a manufacturing method of multi-diffusion of multi-chip PN junctions, which can realize the purpose of solving the problem that the color of the front and back sides is not easy to distinguish after multi-chip manufacturing of PN junctions .

[0033] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

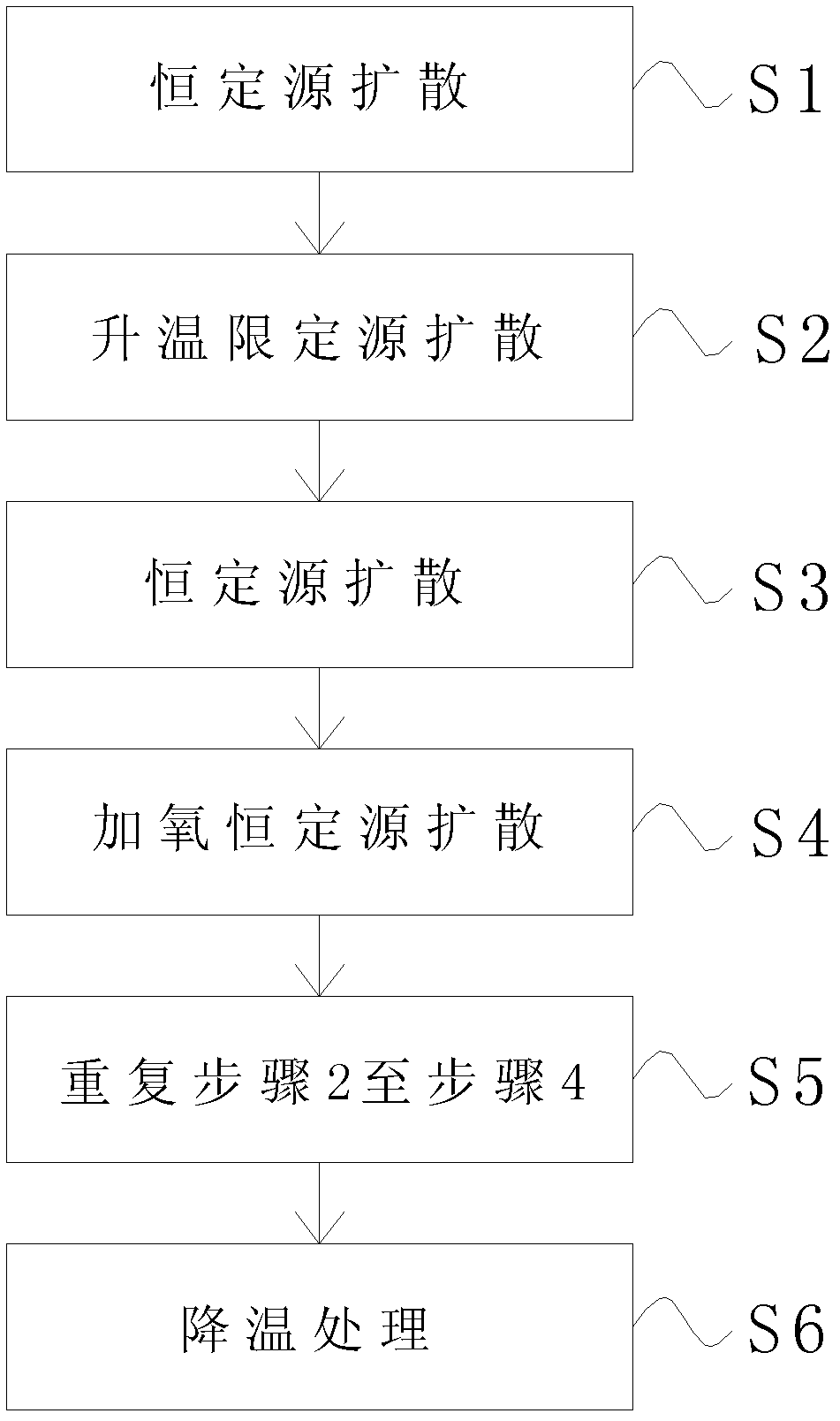

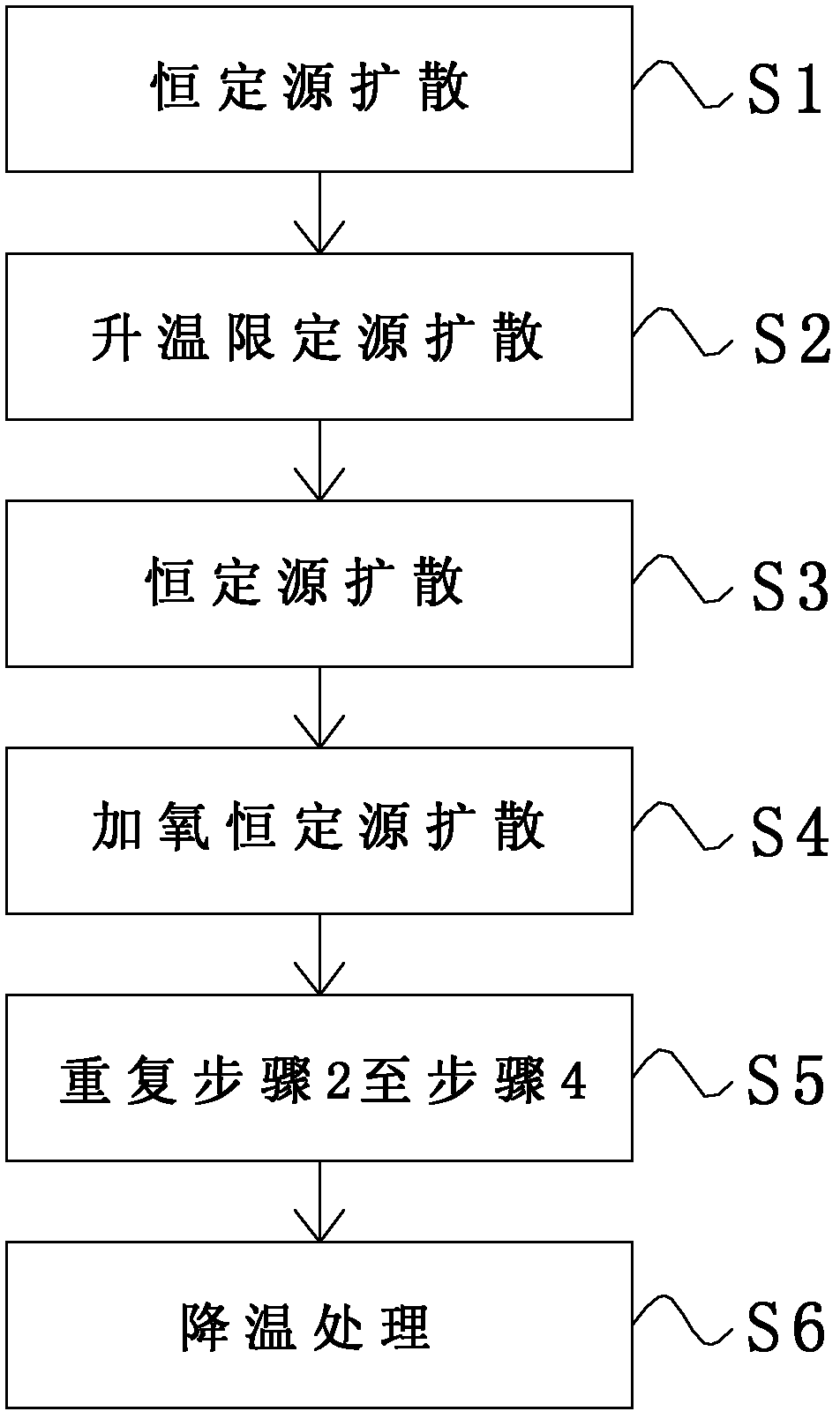

[0034] Please refer to figure 2 , figure 2 It is a flow chart of the multi-diffusion process for PN junctions made of multi-wafers provided by the present invention.

[0035]The invention provides a method for manufacturing multi-diffusion of PN junctions made of multiple wafers, the method comprising: step S1 constant source diffusion, step S2 temperature rise limited source diffusion, step S3 constant source diffusion, ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com