Preparation method of sludge and kitchen waste biochar soil heavy metal passivator

A heavy metal passivator, kitchen waste technology, applied in the restoration of polluted soil, chemical instruments and methods, other chemical processes, etc., can solve the problems of improper disposal, accumulation of heavy metals, etc. Adsorption capacity, effect of preventing and controlling groundwater pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

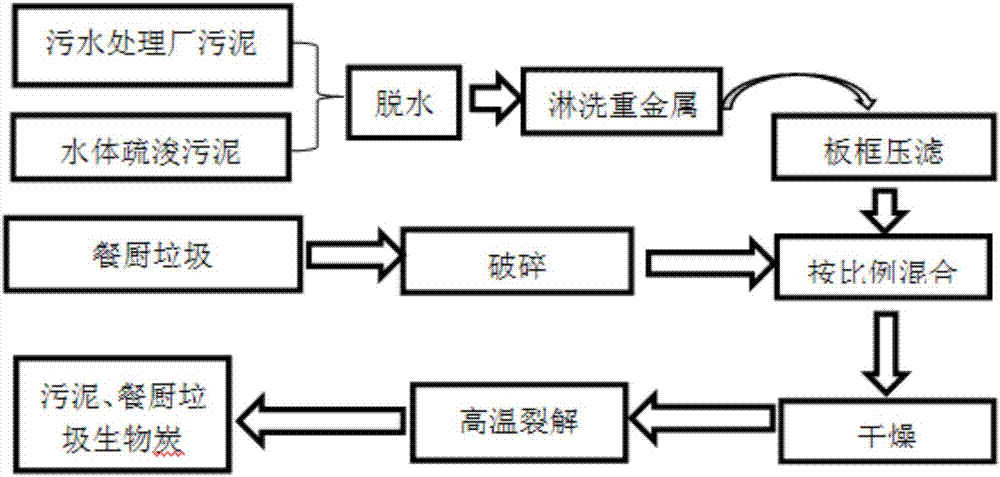

Method used

Image

Examples

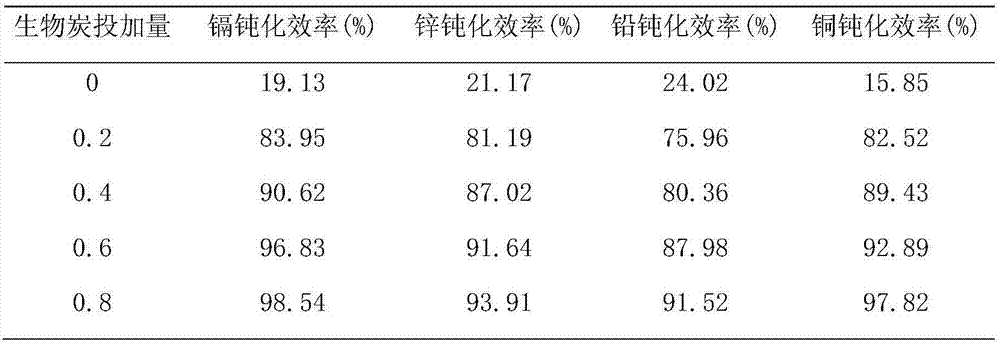

Embodiment 1

[0024] 1) After dehydration treatment of urban sewage treatment plant sludge or water body dredging sludge, add 0.06mol / L oxalic acid solution and 0.08mol / L humic acid solution, the amount of leaching agent per 1kg of sludge is 2L, and rinse to remove Some heavy metals;

[0025] 2) crushing peanut shells, melon seed shells, corncobs, and bagasse until the particle size is less than 2cm, and the kitchen waste is dried fruit shells or peeled vegetables;

[0026] 3) Blend the sludge filtered by the plate and frame filter press with the kitchen waste according to the mass ratio of 10-15:1 to obtain a mixture;

[0027] 4) The mixture is naturally air-dried so that the moisture content is below 10%;

[0028] 5) The dried material in step 4) is crushed, passed through a 100-mesh sieve, placed in a pyrolysis device, and heated to 500-700°C under anaerobic conditions. After firing for 4 hours, let the muffle furnace cool down naturally to 25 °C, sludge biochar can be obtained.

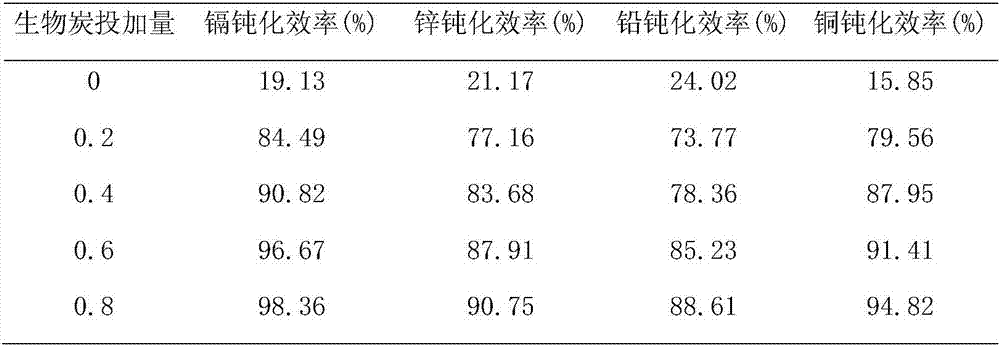

Embodiment 2

[0030] 1) After the sludge from the urban sewage treatment plant is dehydrated by the sludge dehydrator, add 0.09mol / L citric acid solution, 0.03mol / L ethylenediaminetetraacetic acid solution, 0.013mol / L ferric chloride solution, The amount of leaching agent in the mud is 3L, and some heavy metals are removed by leaching;

[0031] 2) crushing corn cobs, bagasse, fruit peels, and vegetable stems and leaves until the particle size is less than 2 cm;

[0032] 3) Blend the sludge filtered by the plate and frame filter press with the kitchen waste according to the mass ratio of 10-15:1 to obtain a mixture;

[0033] 4) Dry the mixture in a dryer at 400°C so that the moisture content is below 10%;

[0034] 5) The dried material in step 4) is crushed, passed through a 100-mesh sieve, placed in a pyrolysis device, and heated to 500-700°C under anaerobic conditions. After firing for 4 hours, let the muffle furnace cool down naturally to 25 °C, sludge biochar can be obtained.

[0035]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Average adsorption capacity | aaaaa | aaaaa |

| Average adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com