Method for preparing electrocatalyst for cathode of ferromagnetic fuel cell

A fuel cell cathode, electrocatalyst technology, applied in battery electrodes, circuits, electrical components, etc., to achieve the effect of improving activity and increasing oxygen flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Step (1) is exactly the same as Comparative Example 1.

[0028] (2) The carbon-supported fuel cell electrocatalyst (PtFe / C) prepared in step (1) was heat-treated at 700 °C for 2 hours in an Ar atmosphere, and the heating rate was 10 °C / min from room temperature to 700 °C, and then cooled to room temperature in the furnace to obtain Ferromagnetic fuel cell cathode electrocatalyst (PtFe / C-700), wherein the mass percentage of the active metal component PtFe in the ferromagnetic fuel cell cathode electrocatalyst (PtFe / C-700) is 20%.

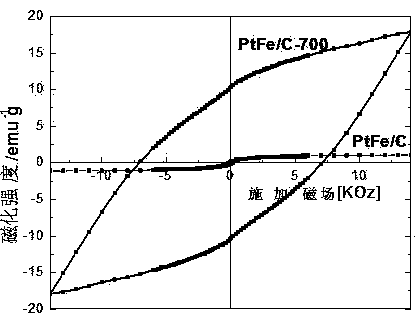

[0029] Magnetic performance test: from figure 1 It can be seen that the ferromagnetic fuel cell cathode electrocatalyst (PtFe / C-700) prepared in Example 1 has a very obvious hysteresis loop, so it is an obvious ferromagnetic catalyst.

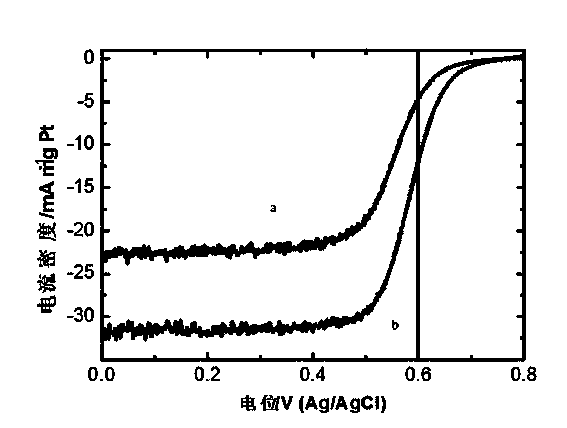

[0030] Catalytic performance test: from figure 2 It can be seen from the curve b in the figure that the oxygen reduction current density of the ferromagnetic fuel cell cathode electrocatalyst (PtFe / C-700) pr...

Embodiment 2

[0034] Step (1) is exactly the same as Comparative Example 2.

[0035] (2) The carbon-supported fuel cell electrocatalyst (PtFe / C) prepared in step (1) was heat-treated in an Ar atmosphere at 800°C for 40 minutes, from room temperature to 800°C at a heating rate of 10°C / min, and then cooled in the furnace to room temperature to obtain Ferromagnetic fuel cell cathode electrocatalyst (PtFe / C-800), wherein the mass percentage of the active metal component PtFe in the ferromagnetic fuel cell cathode electrocatalyst (PtFe / C-800) is 40%.

[0036] Magnetic test and catalytic performance test: After testing, the carbon-supported fuel cell electrocatalyst (PtFe / C) prepared in Comparative Example 2 is a superparamagnetic catalyst, while the ferromagnetic fuel cell cathode electrocatalyst (PtFe / C-800 ) is a ferromagnetic catalyst; the oxygen reduction current density of the ferromagnetic fuel cell cathode electrocatalyst (PtFe / C-800) prepared in Example 2 is 20mA / mg Pt (0.6V), compared w...

Embodiment 3

[0042] Step (1) is exactly the same as Comparative Example 2.

[0043] (2) The electrocatalyst prepared in step (1) was prepared in N 2 Heat treatment at 800°C in the atmosphere for 1 hour, the temperature rise rate from room temperature to 800°C is 10°C / min, and then cool in the furnace to room temperature to obtain a ferromagnetic fuel cell cathode electrocatalyst (PtCo / C-800), in which the active metal component PtCo is in the iron The mass percentage in the cathode electrocatalyst (PtCo / C-800) of the magnetic fuel cell is 30%.

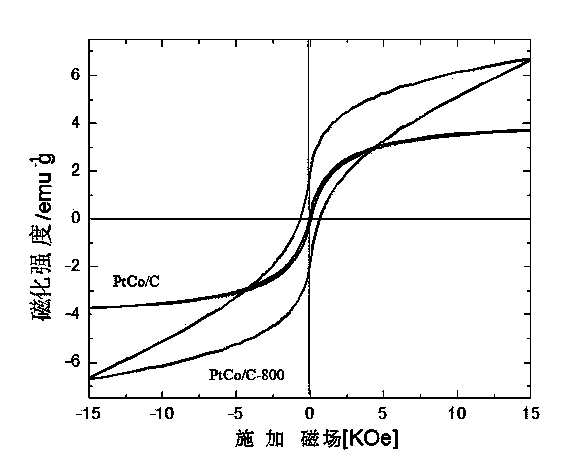

[0044] Magnetic performance test: from image 3 It can be seen that the ferromagnetic fuel cell cathode electrocatalyst (PtCo / C-800) prepared in Example 3 has an obvious hysteresis loop, so it is a ferromagnetic catalyst.

[0045] Catalytic performance test: The oxygen reduction current density of the ferromagnetic fuel cell cathode electrocatalyst (PtCo / C-800) prepared in Example 3 is 6mA / mg Pt (0.6V), which is 50% higher than that in Comparativ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com