Aluminum-containing biphase mixed conductor oxygen permeation membrane material with good stability and preparation method thereof

A hybrid conductor, oxygen-permeable membrane technology, applied in separation methods, semi-permeable membrane separation, chemical instruments and methods, etc., can solve the problems of large linear expansion coefficient, poor mechanical strength, low oxygen permeability rate, etc., and achieve good mechanical properties. , good stability, surface dense effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

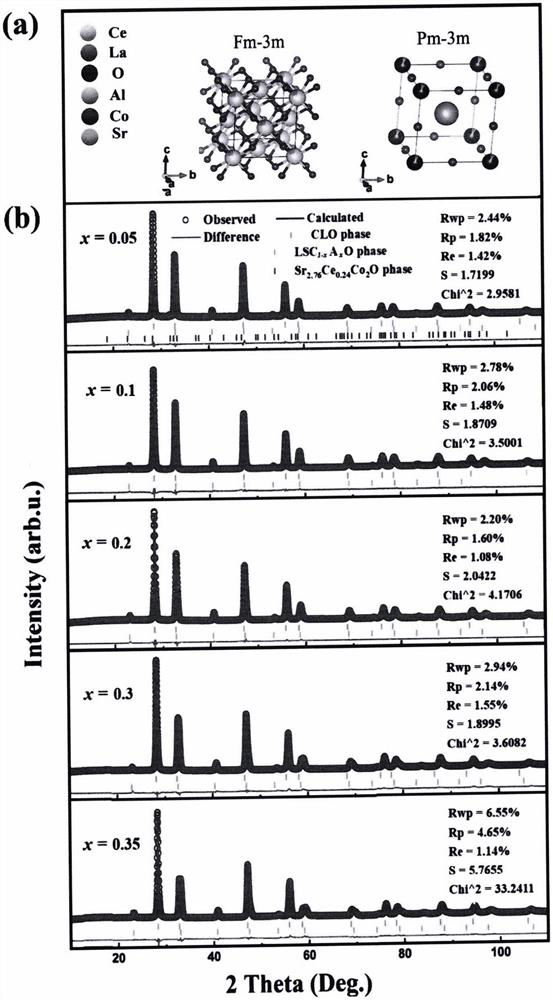

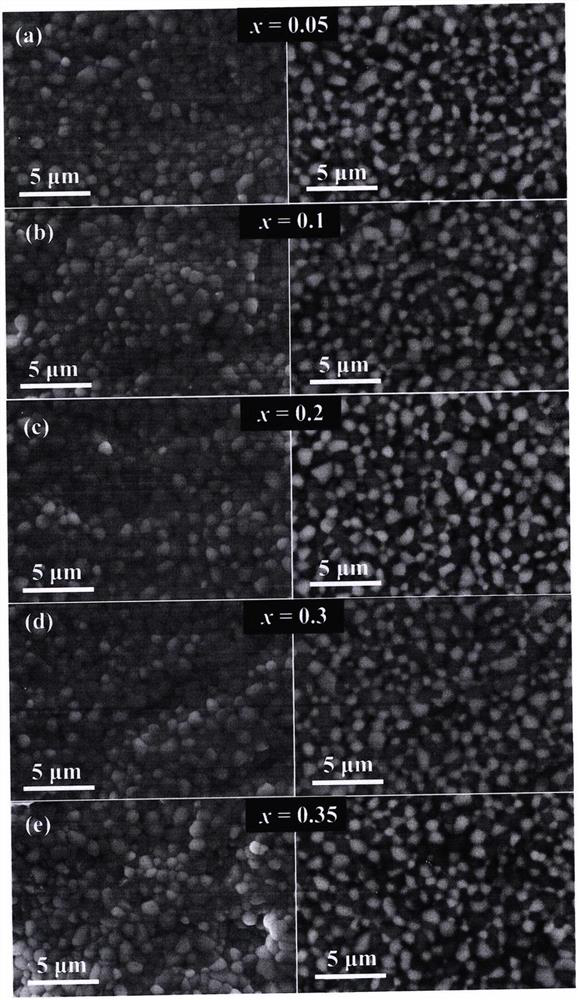

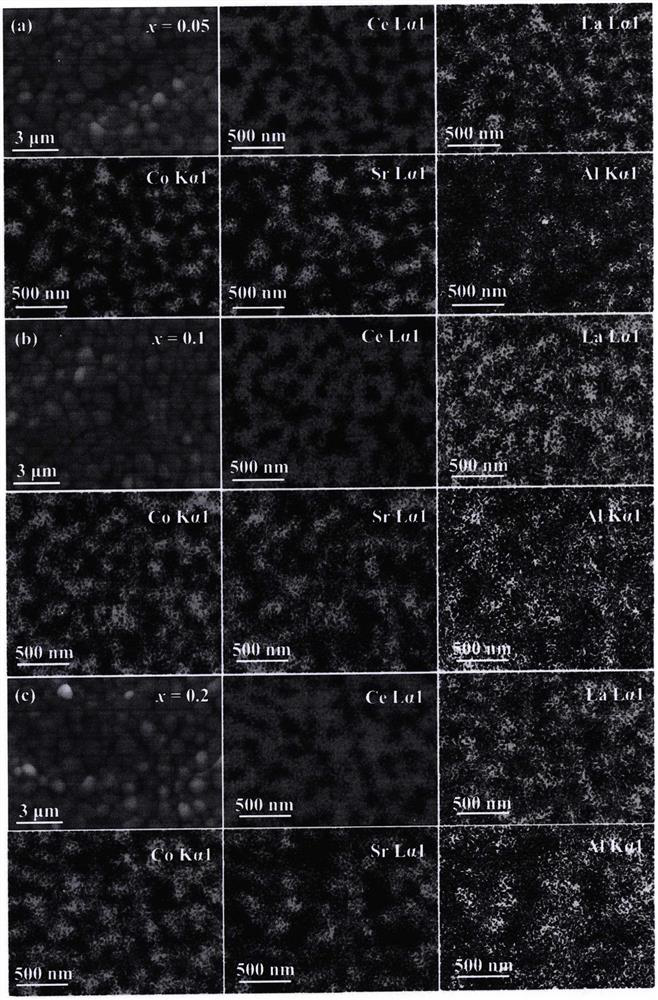

[0026] Accurately weigh 3.0781g La(NO 3 ) 3 , 0.7606g Sr(NO 3 ) 2 , 2.4966g Co(NO 3 ) 2 ·6H 2 O, 0.1694g Al(NO 3 ) 2 9H 2 O, 6.8507g Ce(NO 3 ) 2 ·6H 2 O, 14.9195g citric acid, add ammonia water to adjust the pH to 7~10, stir the solution until it becomes clear and transparent, put the beaker on a magnetic stirrer, heat and continue to evaporate until it turns into a gel, and then put the gel at 140°C Dry in an oven for 24 hours to obtain a fluffy xerogel, which is fully ground and then placed in a crucible and kept at 600°C for 8 hours for calcination to remove organic matter. Put the calcined powder into the crucible after grinding, and calcined at 950°C for 10 hours to obtain 60% Ce 0.9 La 0.1 o 2-δ -40% La 0.6 Sr 0.4 co 1-x Al x o 3-δ The powder is pressed at 10MPa to obtain a cake-shaped sheet, and the sheet is slowly heated up at 1250°C for 5 hours and sintered to obtain a dense dual-phase ceramic oxygen-permeable membrane material, and sanded to obtain...

Embodiment 2

[0028] Accurately weigh 3.0948g La(NO 3 ) 3 , 0.7760g Sr(NO 3 ) 2 , 2.3822g Co(NO 3 ) 2 ·6H 2 O, 0.3412g Al(NO 3 ) 2 9H 2 O, 6.8507g Ce(NO 3 ) 2 ·6H 2 O, 14.9738g citric acid, add ammonia water to adjust the pH to 7~10, stir the solution until it becomes clear and transparent, put the beaker on a magnetic stirrer, heat and continue to evaporate until it turns into a gel, and then put the gel at 140°C Dry in an oven for 24 hours to obtain a fluffy xerogel, which is fully ground and then placed in a crucible and kept at 600°C for 8 hours for calcination to remove organic matter. Put the calcined powder into the crucible after grinding, and calcined at 950°C for 10 hours to obtain 60% Ce 0.9 La 0.1 o 2-δ -40% La 0.6 Sr 0.4 co 1-x Al x o 3-δ The powder is pressed at 10MPa to obtain a cake-shaped sheet, and the sheet is slowly heated up at 1250°C for 5 hours and sintered to obtain a dense dual-phase ceramic oxygen-permeable membrane material, and sanded to obtain...

Embodiment 3

[0030] Accurately weigh 3.1290g La(NO 3 ) 3 , 0.7772g Sr(NO 3 ) 2 , 2.1484g Co(NO 3 ) 2 ·6H 2 O, 0.6923g Al(NO 3 ) 2 9H 2 O, 6.8507g Ce(NO 3 ) 2 ·6H 2 O, 15.0848g citric acid, add ammonia water to adjust the pH to 7~10, stir the solution until it becomes clear and transparent, put the beaker on a magnetic stirrer, heat and continue to evaporate until it turns into a gel, and then put the gel at 140°C Dry in an oven for 24 hours to obtain a fluffy xerogel, which is fully ground and then placed in a crucible and kept at 600°C for 8 hours for calcination to remove organic matter. Put the calcined powder into the crucible after grinding, and calcined at 950°C for 10 hours to obtain 60% Ce 0.9 La 0.1 o 2-δ -40% La 0.6 Sr 0.4 co 1-x Al x o 3-δ The powder is pressed at 10MPa to obtain a cake-shaped sheet, and the sheet is slowly heated up at 1250°C for 5 hours and sintered to obtain a dense dual-phase ceramic oxygen-permeable membrane material, and sanded to obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com