Treatment technique for strengthening surface through concurrent infiltrations from five aspects for tire mold

A tire mold and surface strengthening technology, which is applied in the direction of metal material coating process, coating, solid diffusion coating, etc., can solve the problems of unbearable contact stress load, hardness decrease, slow penetration rate, etc., to overcome the corrosion phenomenon, Good performance and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

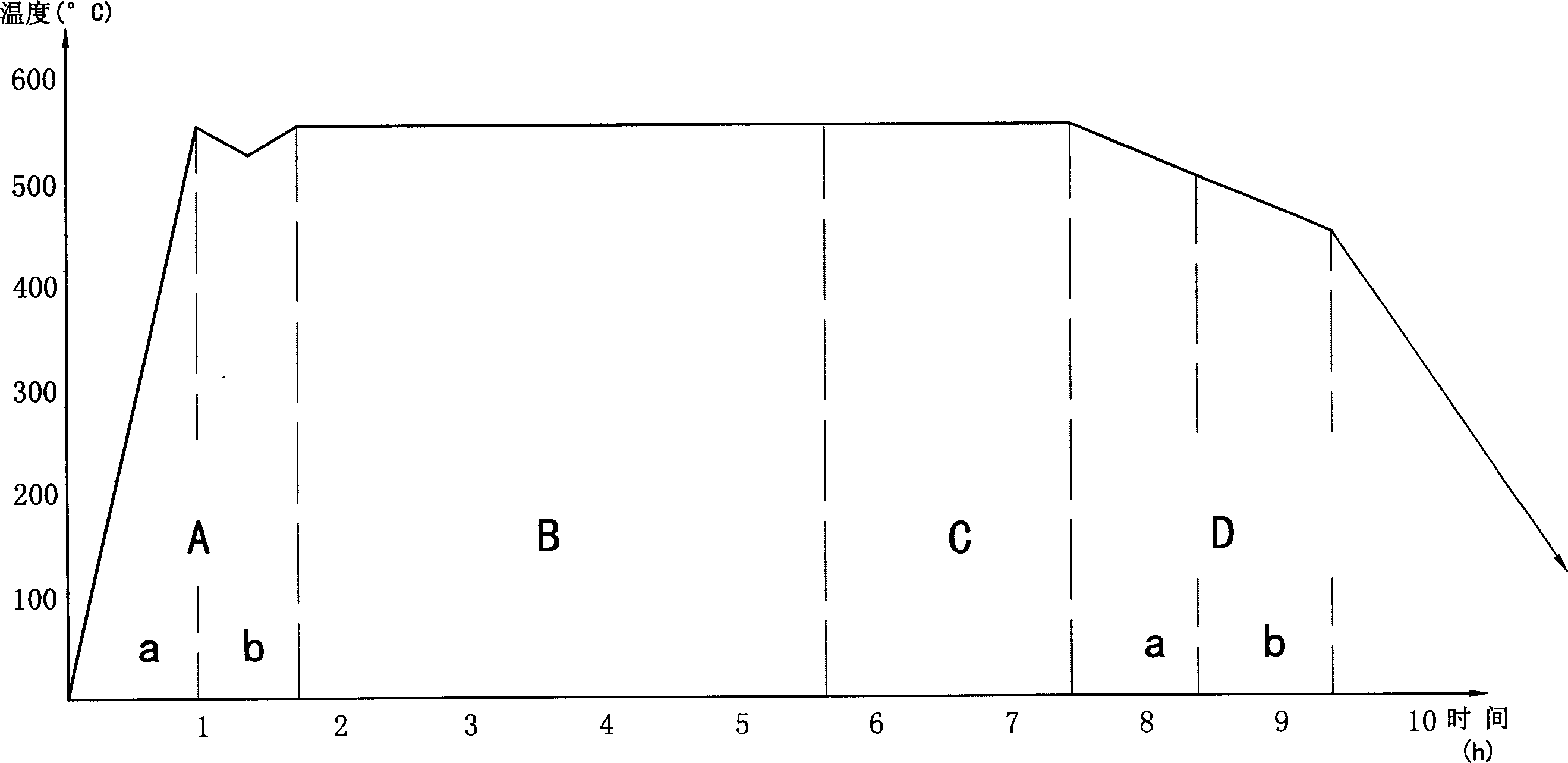

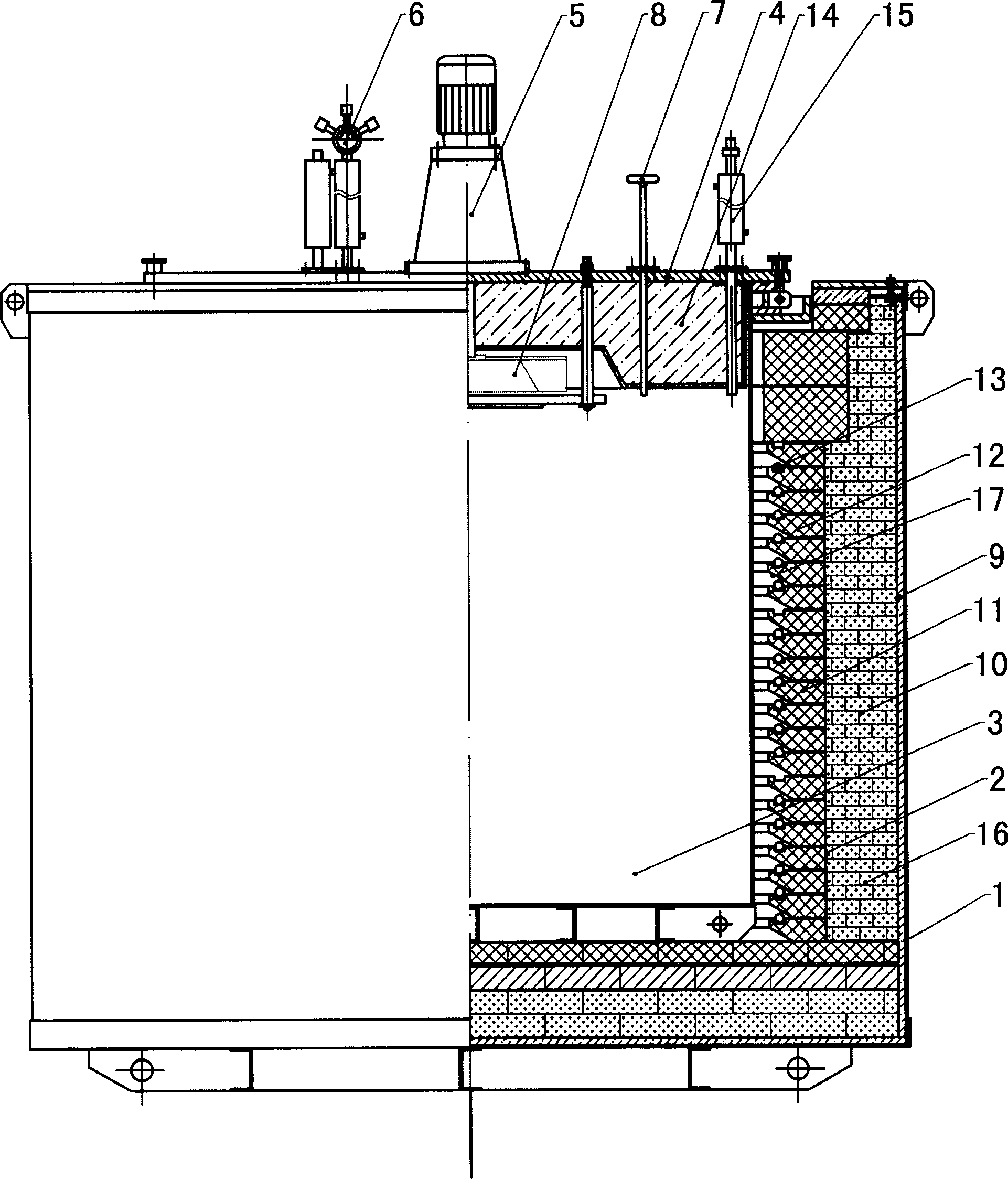

[0037] Example of five-component co-infiltration surface strengthening treatment process for tire molds:

[0038]The slider with the composition of 0.42%~0.48%C, 0.17%~0.37%Si, 0.50%~0.80%Mn,<0.03%P,<0.03S is placed in the co-osmosis tank together with the sponge titanium, and the large flux is dropped into methanol Exhaust until the temperature of the workpiece reaches 550°C; ethanol and rare earth organic solutions are dripped in at a rate of 60-80d / min respectively, the ammonia flux is controlled to 40%-55%, and the oxygen flux is controlled to account for the furnace The total gas volume is 0.1-0.2%, the control pressure is +130-160mm water column, and the strong infiltration time is 3-4h; then the ammonia gas flux controls the ammonia decomposition rate to 75%-85%, and the control pressure is +130-160mm water column, The time is 1.5~2h; then only ammonia gas is passed, the ammonia decomposition rate is controlled to be over 80%, the control pressure is +130~160mm water co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com