Multi-adsorption column for an oxygen generator, and control method thereof

An adsorption tower and generator technology, which is applied in the field of multiple adsorption tower devices for oxygen generators, can solve the problems of large oxygen generator installation space, difficulty in installing oxygen generators, and increased replacement costs, and achieves easy installation and reduced costs. , The effect of reducing installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention to achieve the above objects will be described in detail below with reference to the accompanying drawings.

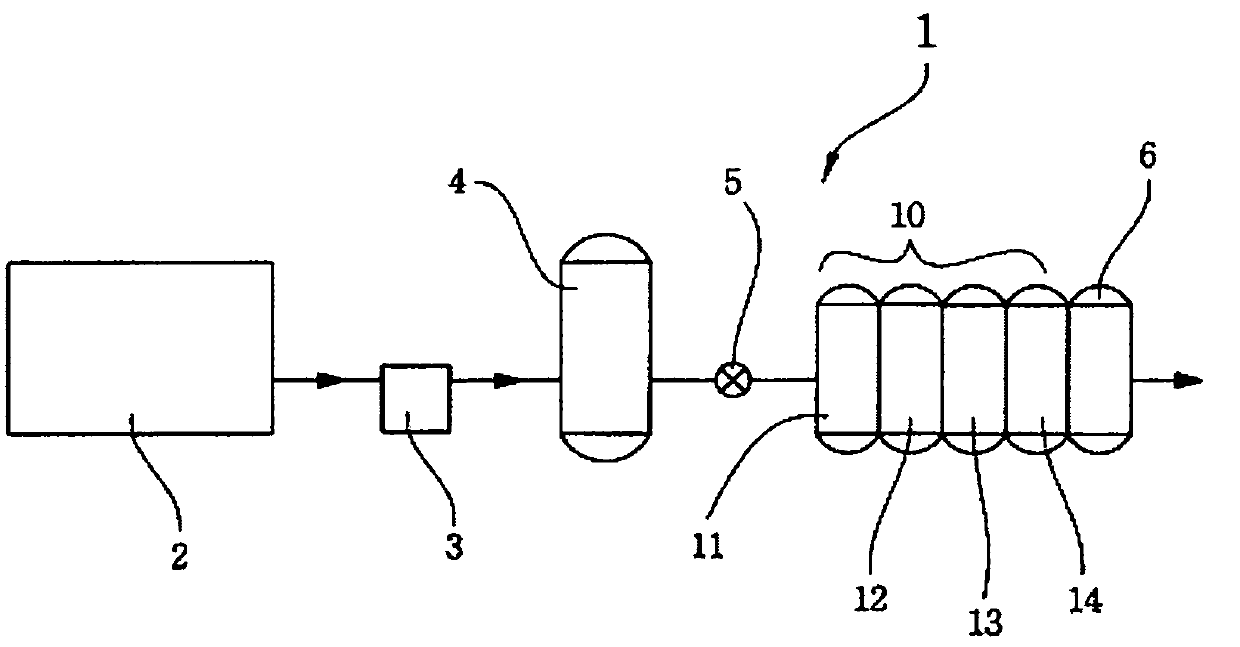

[0036] At first, according to the present invention, the simple composition of the oxygen generator 1 that is equipped with multiple adsorption towers, such as figure 1 As shown in , the air compressor 2 (air compressor), air dryer 3 (air dryer), air storage tank 4 and pressure regulator 5 are connected to the compressed air supply pipe and installed in the multiple adsorption tower 10. The inlet side of the multiple adsorption tower 10 is connected to the outlet side of the nitrogen gas storage tank 6.

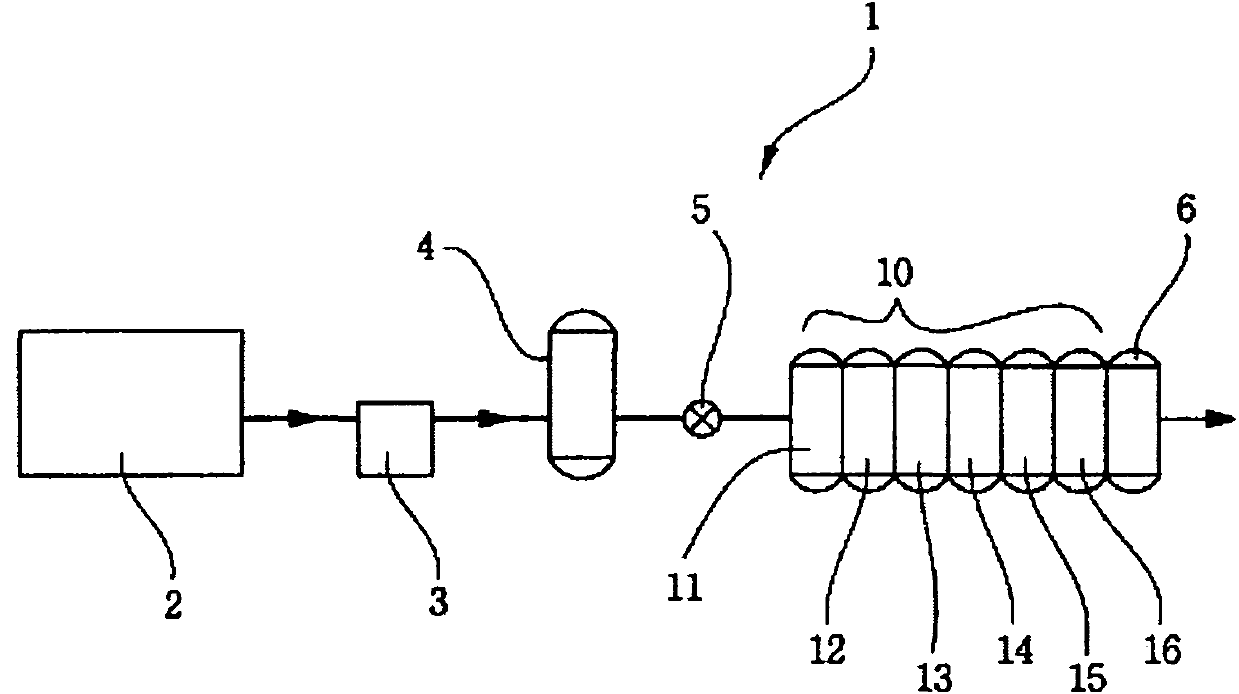

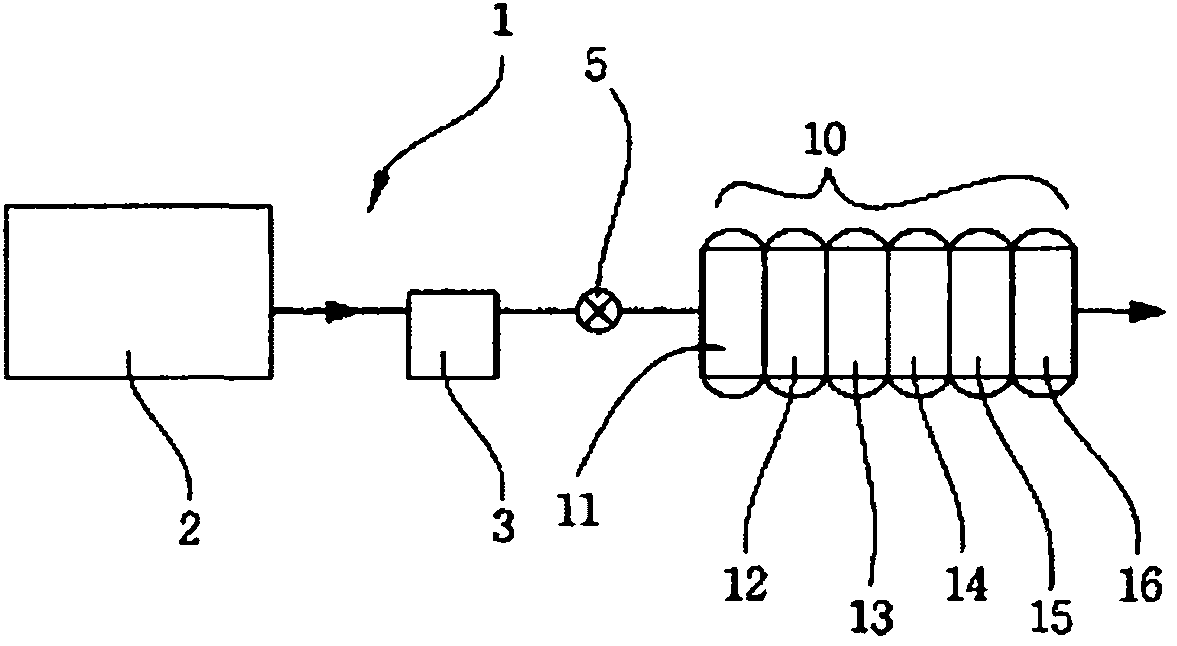

[0037] figure 1 The content shown in is that four adsorption towers between the first adsorption tower 11 and the fourth adsorption tower 14 are installed to form two multiple adsorption towers 10, figure 2 and image 3 1 and 2 respectively represent the situation that a total of six adsorption towers between the first adsorption tower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com