Gibberella and method for fermentation production of gibberellin GA4+7

A technology of gibberellum and fermentation medium, applied in the field of fermentation engineering, can solve problems such as few strains reported

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

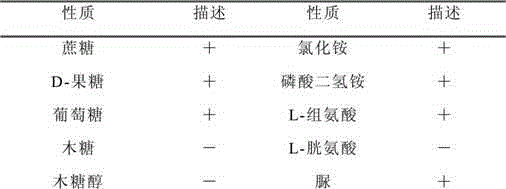

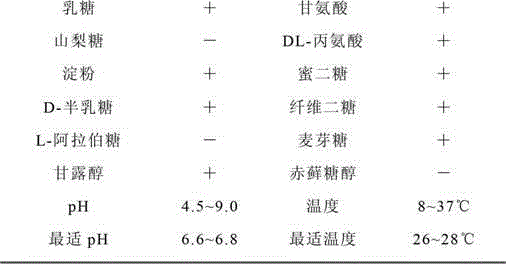

Image

Examples

Embodiment example 1

[0026] Plate culture: The Gibberellin strain NJYHWG32261 was connected to the PDA medium, cultured for 2 days at pH 6.0, temperature 32°C, and activated Gibberella colonies were obtained; the composition of the PDA medium was (g / L): Potato juice 250, glucose 10, agar 15;

[0027] Seed culture: Pick an activated Gibberella colony from the PDA medium and place it in a shake flask containing the seed medium. At pH 6.0, the culture temperature is 32°C, the rotating speed of the shaker is 160 rpm, and the seed liquid is obtained by culturing for 2 days ; The amount of seed culture medium is 10% of the volume of the shake flask; the seed culture medium is (g / L): glucose 30, NH 4 NO 32.0, MgSO 4 ·7H 2 O 1.0, KH 2 PO 4 ·3H 2 O1.0;

[0028] Fermentation culture: Inoculate the seed liquid in a shaker flask containing the fermentation culture liquid at a ratio of 5% of the volume of the fermentation medium, pH 6.0, culture temperature 32℃, shaker rotation speed 160rpm, and increase the shaker...

Embodiment example 2

[0030] Plate culture: The Gibberella spp. NJYHWG32261 strain was cultured on the PDA medium, cultured at pH 6.5, the culture temperature was 28 ℃, and cultivated for 3 days to obtain activated Gibberella colonies; the composition of the PDA medium was (g / L ): Potato juice 150, glucose 30, agar 20;

[0031] Seed culture: Pick 2 activated Gibberella colonies from the PDA medium and place them in the shake flask containing the seed medium. At pH 6.5, the culture temperature is 28°C, the rotating speed of the shaker is 180 rpm, and the seed solution is cultured for 3 days. ; The amount of seed culture medium is 15% of the volume of the shake flask; the seed culture medium is (g / L): glucose 40, NH 4 NO 3 1.0, MgS O 4 ·7H 2 O 0.8, KH 2 PO 4 ·3H 2 O0.5;;

[0032] Fermentation culture: Inoculate the seed liquid in a shaker flask containing the fermentation culture liquid at a ratio of 8% of the volume of the fermentation medium, pH 6.5, culture temperature 28°C, shaker rotation speed 180rp...

Embodiment example 3

[0034] Plate culture: The Gibberellia strain NJYHWG32261 was cultured on a PDA medium at pH 7.0 and a culture temperature of 26°C for 4 days to obtain activated Gibberella colonies; the composition of the PDA medium was (g / L) : Potato juice 200, glucose 20, agar 18;

[0035] Seed culture: Pick an activated Gibberella colony from the PDA medium and place it in a shake flask containing the seed medium. At pH 7.0, the culture temperature is 26°C, the rotating speed of the shaker is 200 rpm, and the seed solution is obtained by culturing for 4 days; The volume of the seed culture medium is 20% of the volume of the shake flask; the seed culture medium is (g / L): glucose 50, NH 4 NO 3 1.5, MgSO 4 ·7H 2 O 1.2, KH 2 PO 4 ·3H 2 O0.8;;

[0036] Fermentation culture: inoculate the seed liquid in a shaker flask containing the fermentation culture liquid at a ratio of 10% of the volume of the fermentation medium, pH 7.0, culture temperature 26℃, and shaker rotation speed 200rpm; after fermentati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com