Retractable chuck

A telescopic and chuck technology, applied in chucks and other directions, can solve the problems of waste of materials and labor, waste of time, loss of part accuracy, etc., and achieve the effects of shortening processing time, improving accuracy retention, and reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

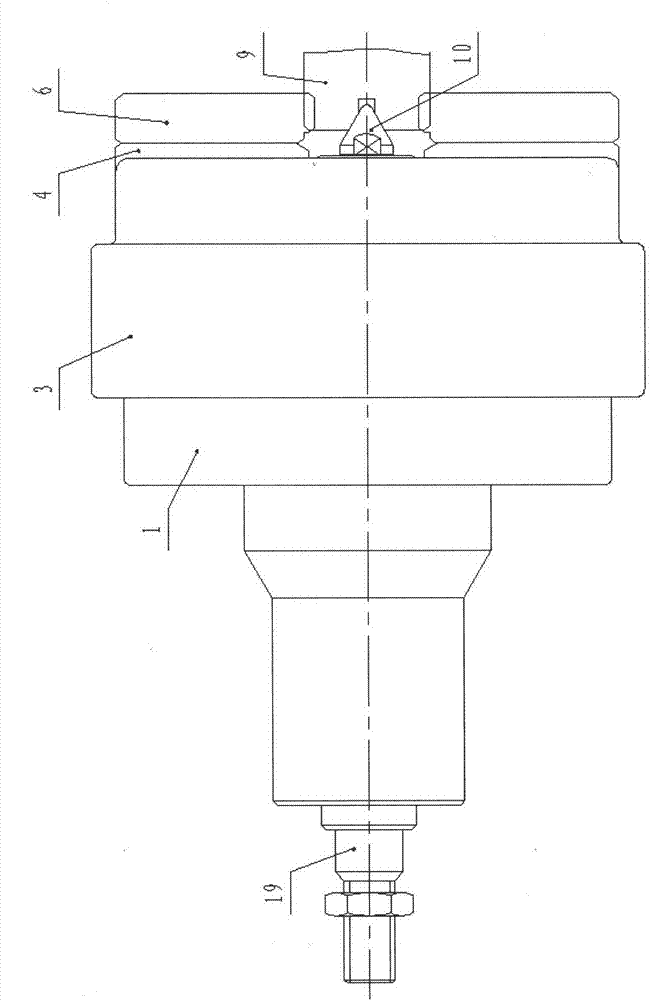

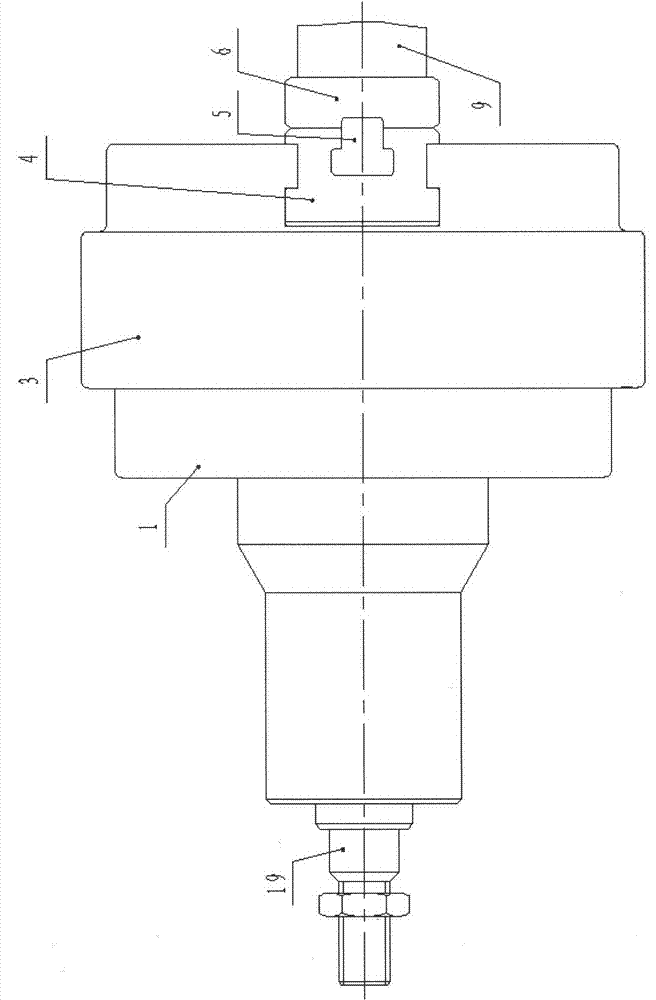

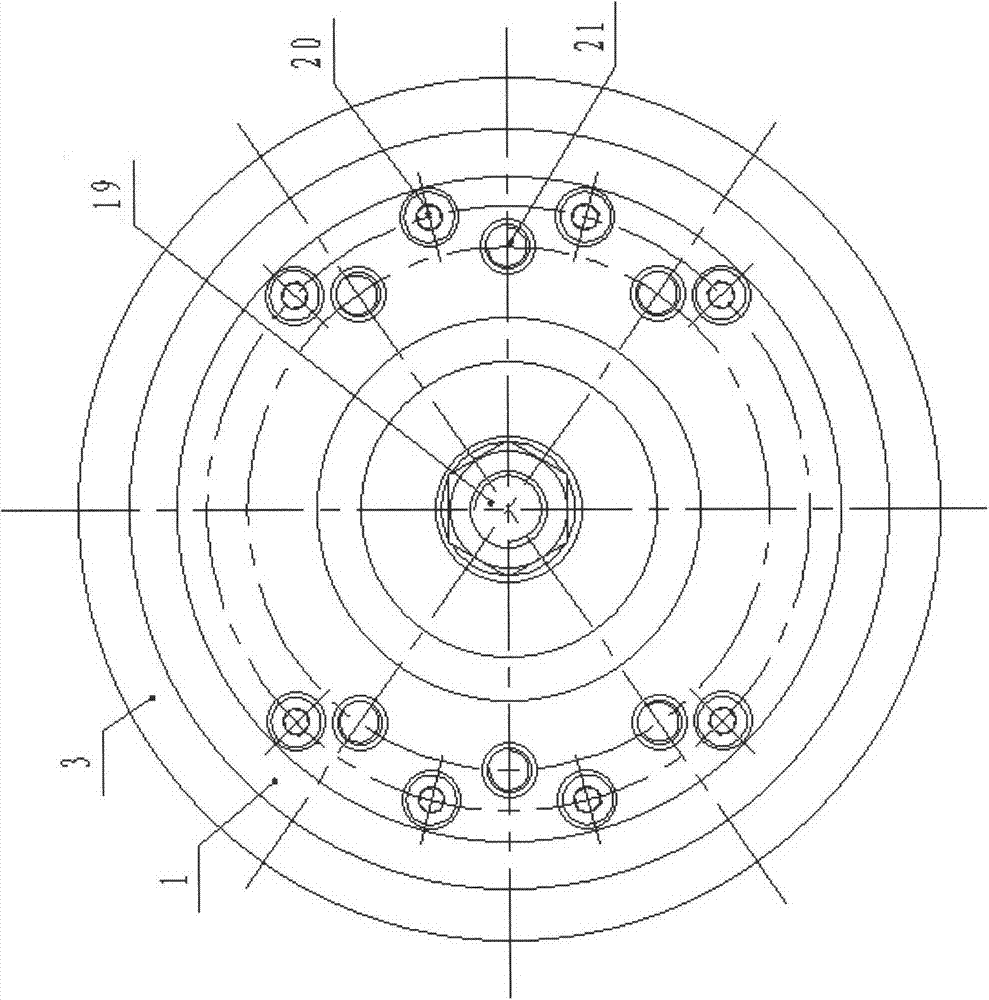

[0015] like figure 1 , figure 2 , image 3 , Figure 4 As shown, the telescopic chuck consists of a chuck seat (1), a center (10), a tie rod (19) and a chuck head. The chuck seat (1) is fixedly mounted on the machine tool spindle (22), and the center (10) Placed in the center of the front end of the chuck, the tail of the pull rod (19) protrudes from the center of the chuck seat (1) and is connected with the power of driving the chuck; A component on the sliding disc body (3) constitutes a chuck head, the chuck head is sleeved on the chuck seat (1) and the chuck core (8), and there are at least two or more clamping claws (6); (19) When pushed forward by external force, the chuck head extends forward, and after the chuck head reaches the limit position forward, the jaw (6) starts to clamp the workpiece; on the contrary, when the pull rod (19) ) is pulled backwards by external force, the jaws (6) release the workpiece, and the chuck head starts to retreat backwards only aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com