A kind of manufacturing method of complex busbar polishing wheel with local reinforcement structure

A technology of local enhancement and manufacturing method, which is applied in the direction of wheels, grinding/polishing equipment, manufacturing tools, etc. of the working part with flexibility, and can solve the problems of large polishing power head, poor precision retention, and difficult polishing tool polishing ability, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

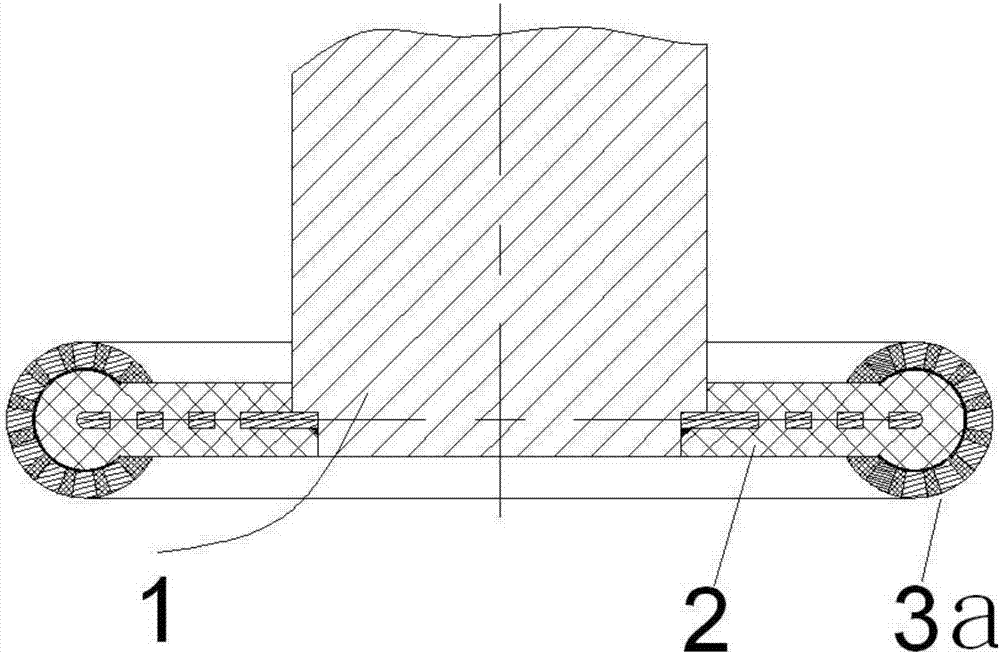

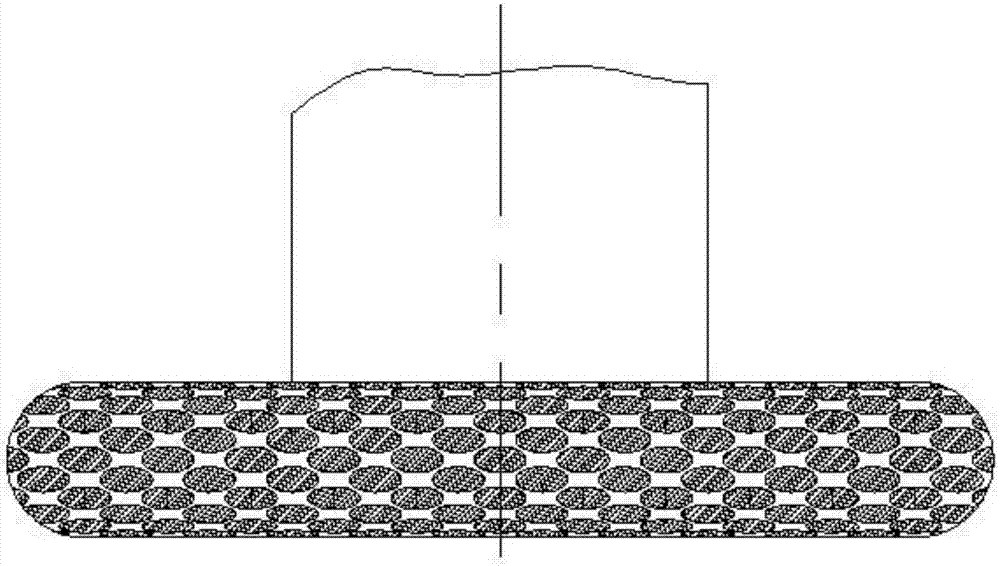

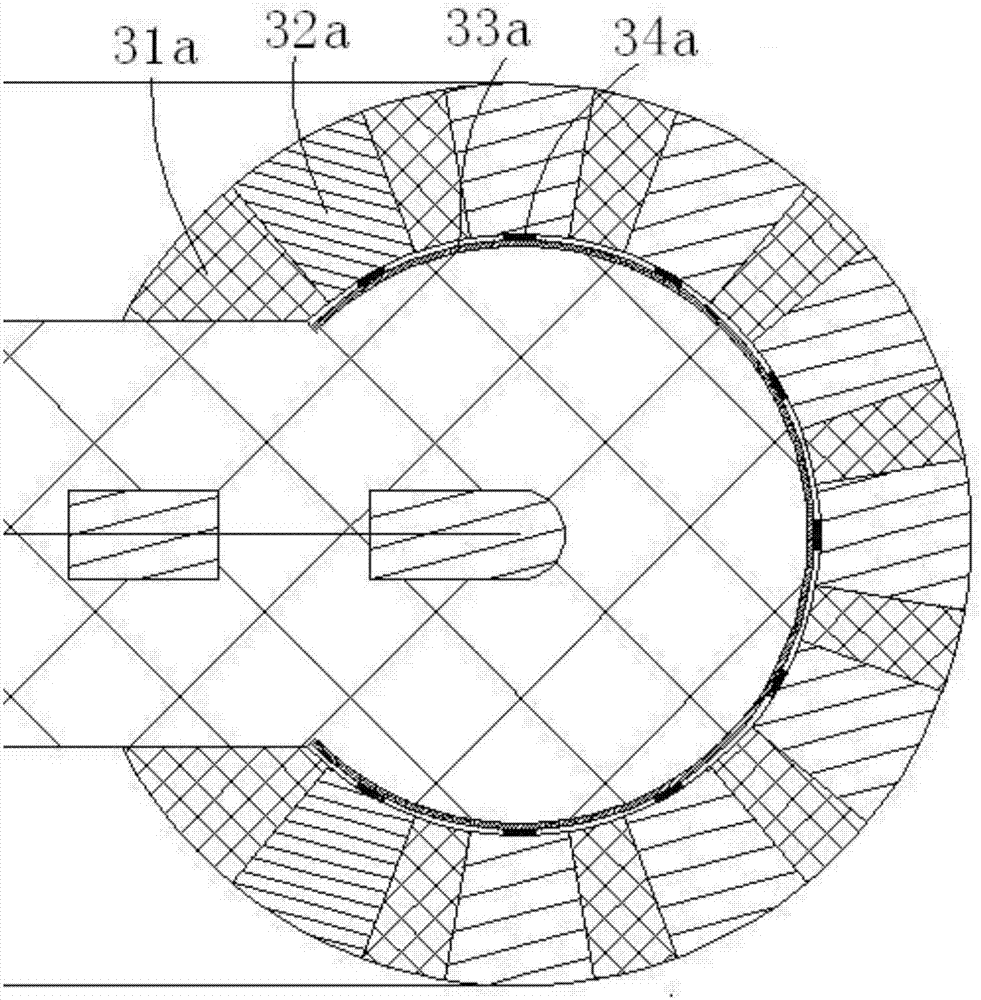

[0083]The basic principle of the present invention is to connect or directly shape the tiny abrasives on or within the abrasive matrix (metal rod, metal sheet, abrasive block) with a larger size so that the abrasive can be stably connected to the matrix for a long time and With high connection strength, these reinforced abrasive substrates with larger dimensions are connected with the elastic larger polishing wheel elastic substrates in a reasonable way to ensure that each tiny abrasive substrate can be elastically polished The position changes on the wheel base body and has less rigidity and good elasticity, and has a larger contact surface and higher connection strength with the elastic base body of the polishing wheel. Through this intermediate reinforcement structure, the connection strength and protrusion height of the superhard abrasive can be significantly improved, so that its strong grinding ability can be fully exerted, thus breaking through the existing combination b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com