High-precision micro-gripper

A micro-clamping and high-precision technology, applied in the field of micro-mechanical assembly tools and micro-grippers, can solve the problem that the clamped parts are easily damaged, the control accuracy of the micro-force of the micro-gripper is low, and the operation accuracy is affected, etc. problems, to achieve the effect of improving force adjustment accuracy, low power consumption, and high precision retention.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

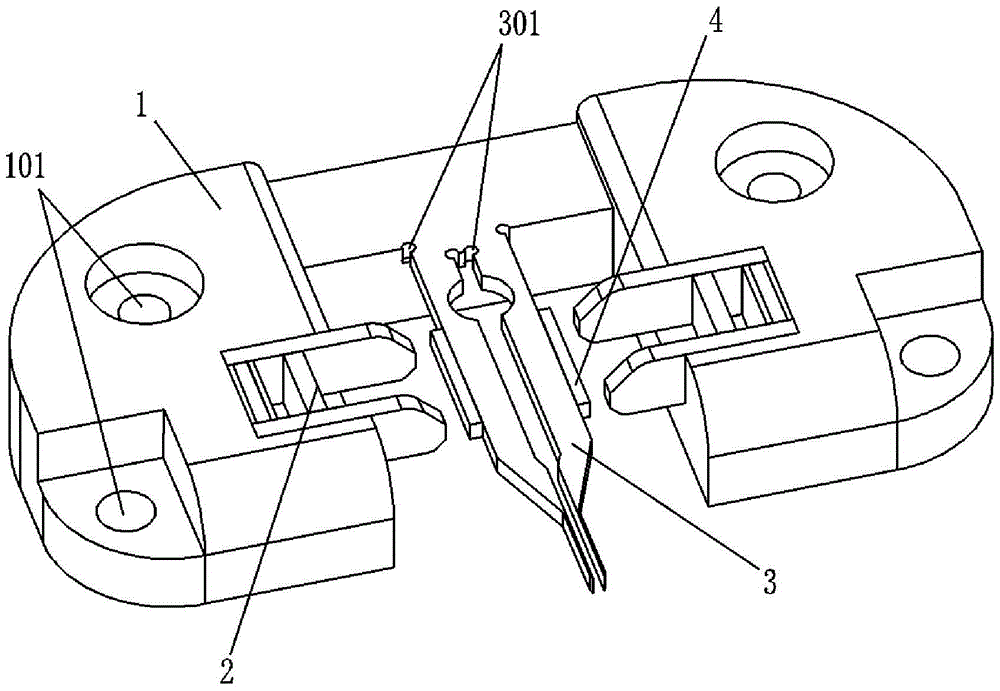

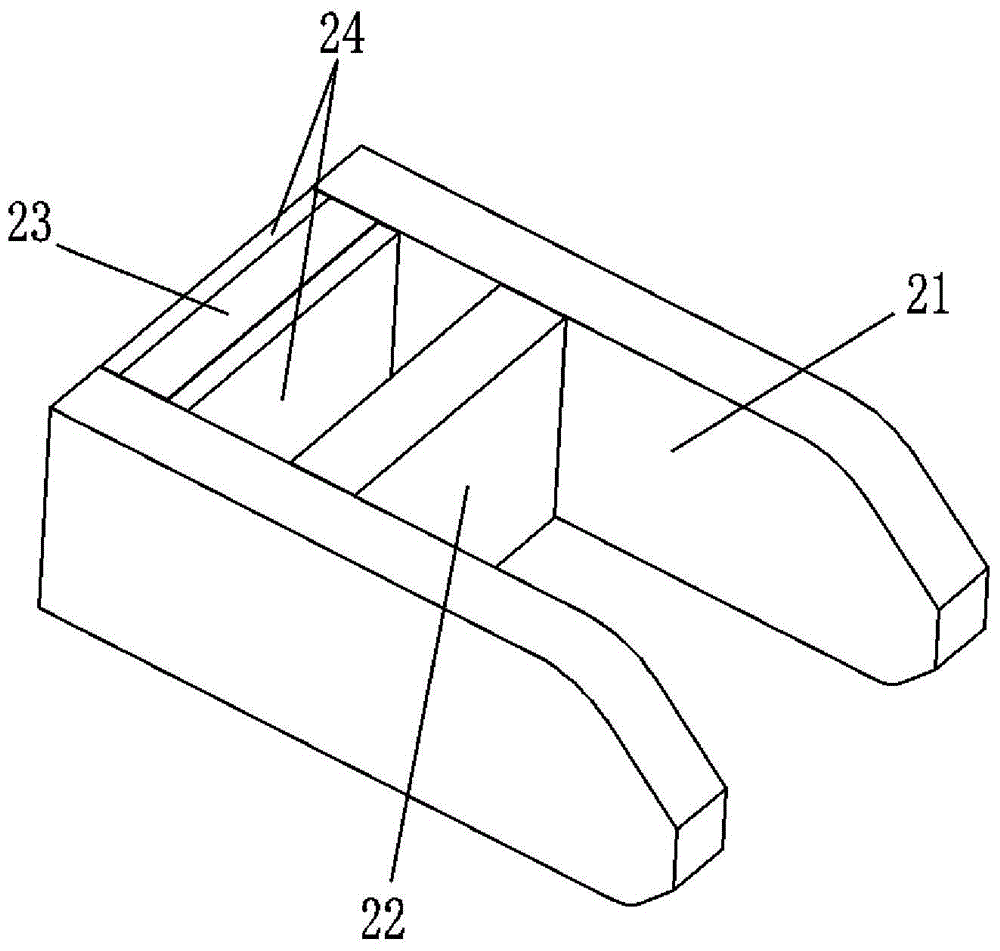

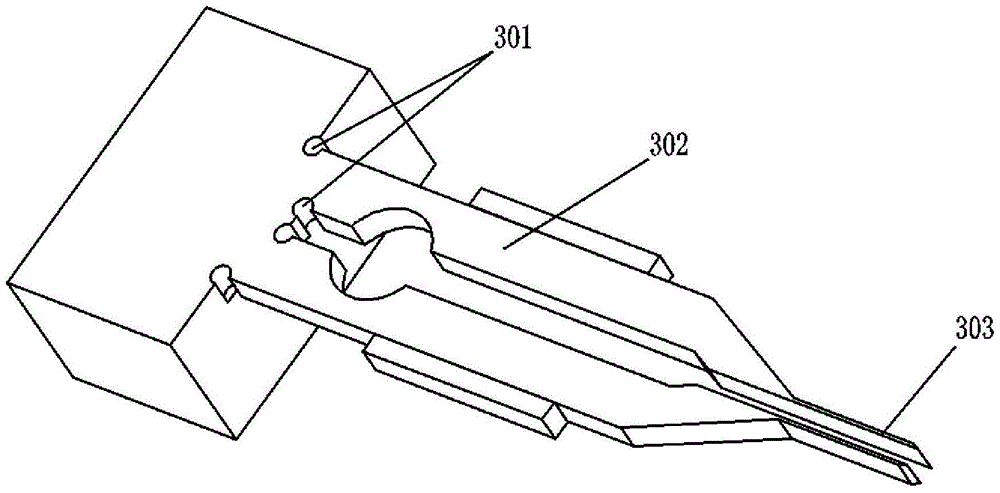

[0016] refer to figure 1 , figure 2 and image 3 , the high-precision micro-gripper of the present invention includes a platform base 1, a micro-force driver 2, a micro-clamping pliers 3 and a force magnet 4; the platform base 1 has a symmetrical structure, and is provided with symmetrically distributed screw holes 101; The micro-force driver 2 is symmetrically arranged on the platform base 1, and the micro-clamping forceps 3 are arranged at the symmetrical central plane of the platform base 1; the micro-force driver 2 includes two piezoelectric ceramic sheets 24, located The giant magnetostrictive sheet 23 between sheet piezoelectric ceramic sheet 24, the permanent magnet 22 that arranges parallel with giant magnetostrictive sheet 23, be positioned at giant magnetostrictive sheet 23, piezoelectric ceramic sheet 24 and permanent magnet 22 two ends and Two magnetic fixed yokes 21 for clamping the giant magnetostrictive sheet 23 and the permanent magnet 22; the micro-clamping...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com