Cutting device of slicer for machining solar panel

A solar cell panel and cutting device technology, which is applied in metal processing and other directions, can solve the problems of unfavorable solar cell panel processing, difficulty in ensuring processing quality, and short accuracy retention time, etc., and achieves simple structure, low cost, and long accuracy retention Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

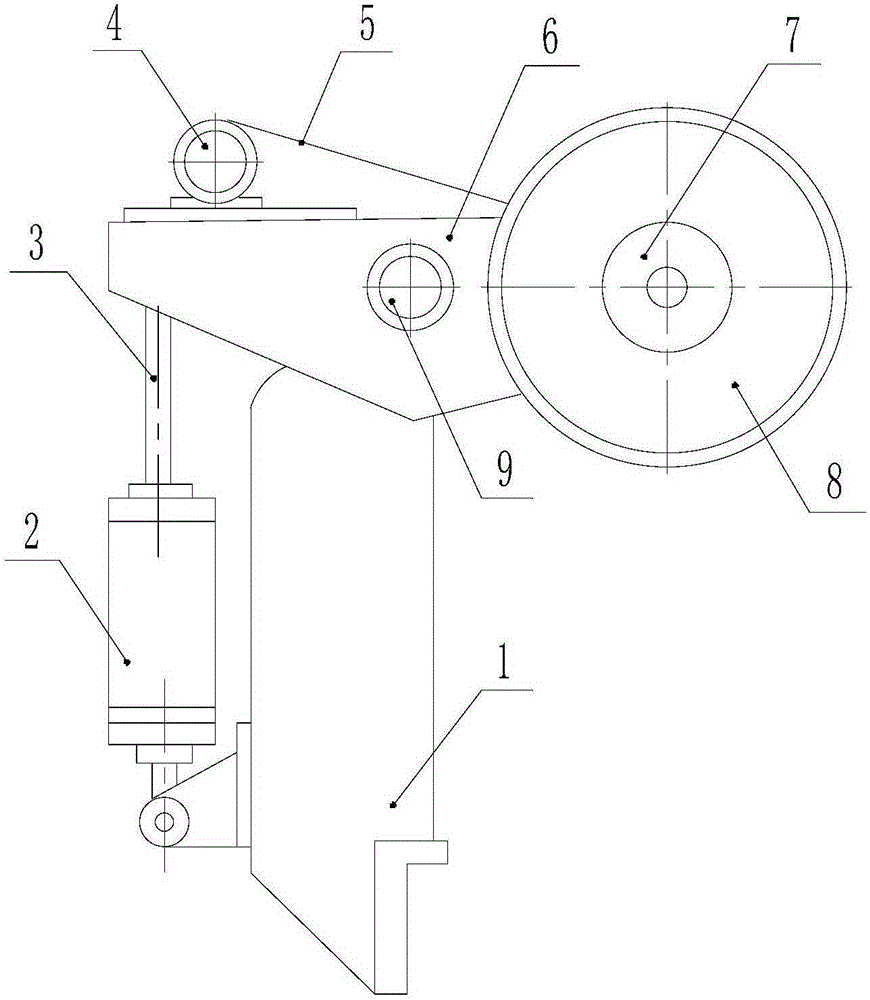

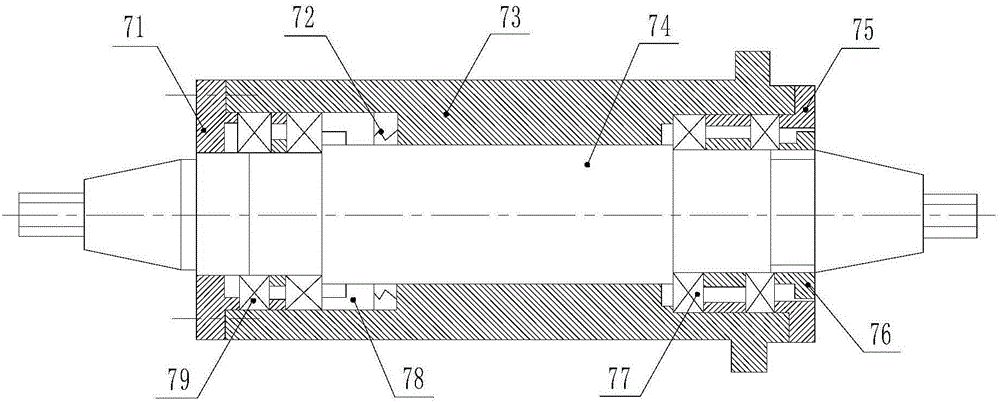

[0016] Examples such as figure 1 with figure 2 As shown, a cutting device for processing a solar panel slicer includes a base, a cutting cylinder, a piston rod, a drive motor, a synchronous toothed belt, a swing arm, a spindle device, a cutter head and a central shaft; the cutting cylinder The bottom end is mounted on the base through a hinge, the top end of the piston rod is mounted on the swing arm through a hinge, the swing arm is mounted on the base through a central axis and can rotate around the central axis, and the drive motor is mounted on the swing arm, A drive pulley is installed on the drive motor, and the main shaft device is composed of a rear cover, a spring, a shell, a main shaft, a front cover, a lock nut, a front bearing group, a disc and a rear bearing group, and the main shaft is installed on the conical surface of the rear end. There is a driven pulley, the driving pulley drives the driven pulley to rotate through the synchronous toothed belt, the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com