Milling cutter with adjustable finish machining face

A technology for finishing surfaces and milling cutters, applied in the field of adjustable finishing surface milling cutters, can solve problems such as the inability to estimate the adjustment accuracy level of the adjustment structure, and the inability to achieve equivalent incremental adjustment in the adjustment behavior, achieving stable angle guarantee, The adjustment operation is convenient and the effect of reducing deflection error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

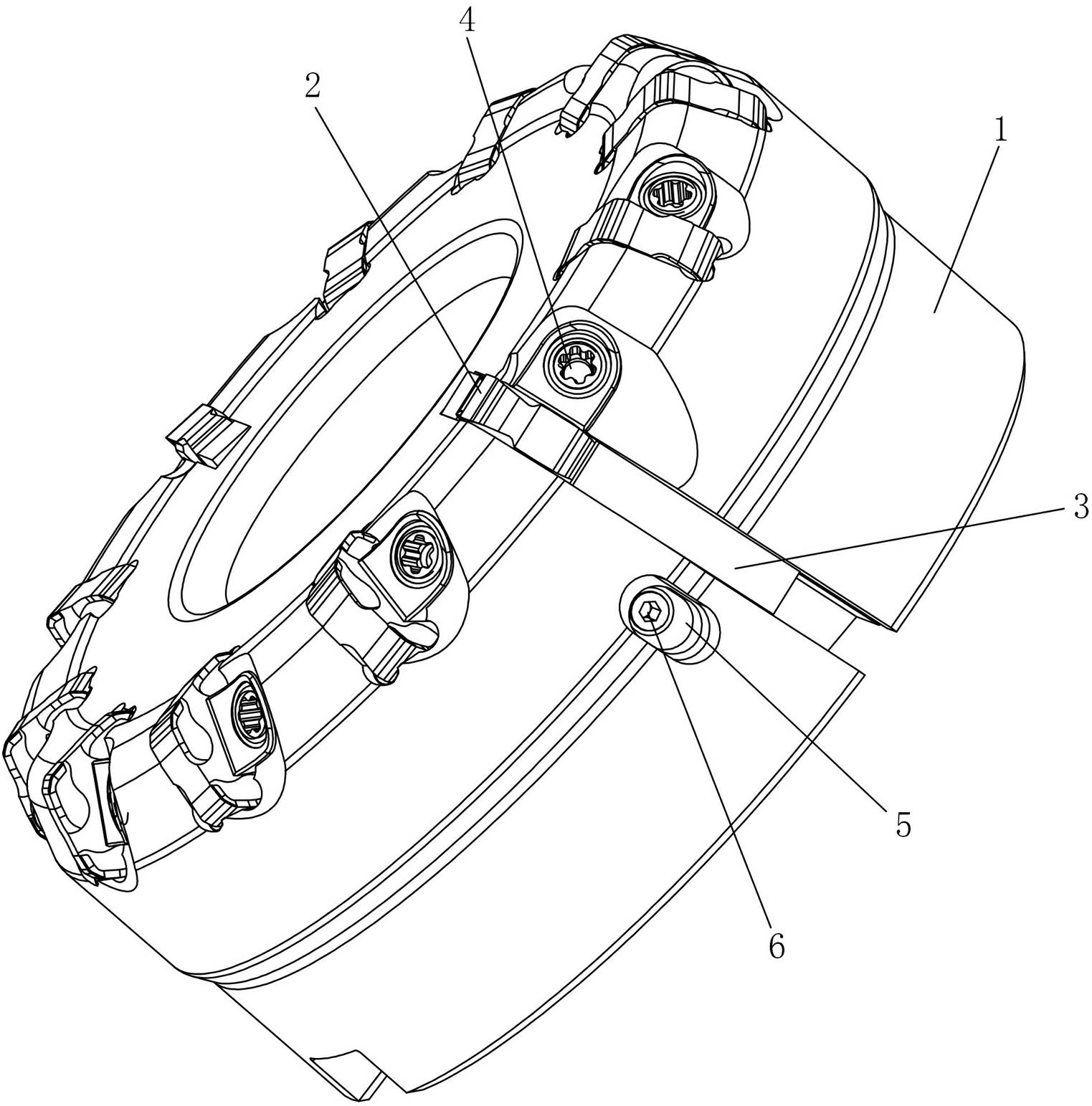

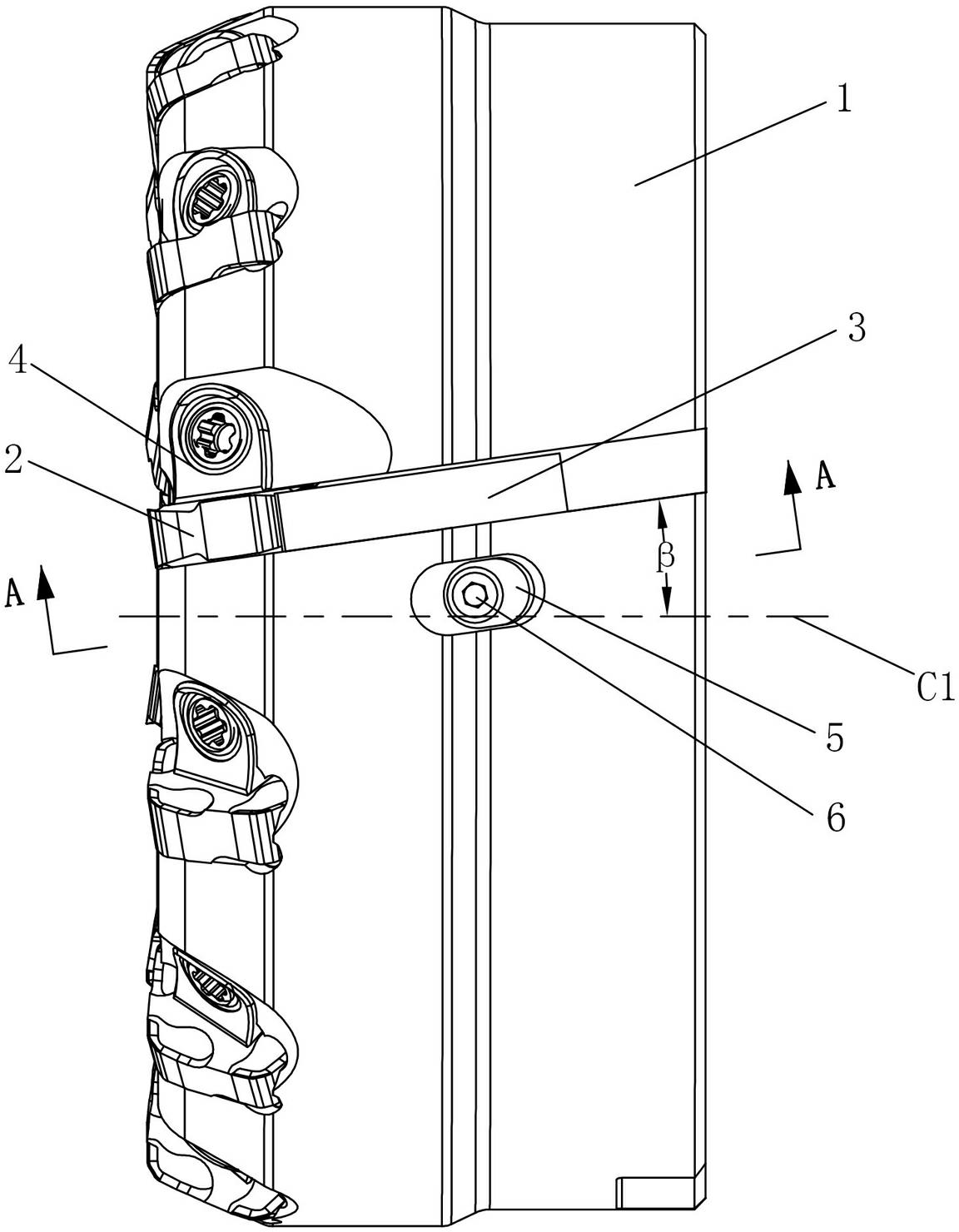

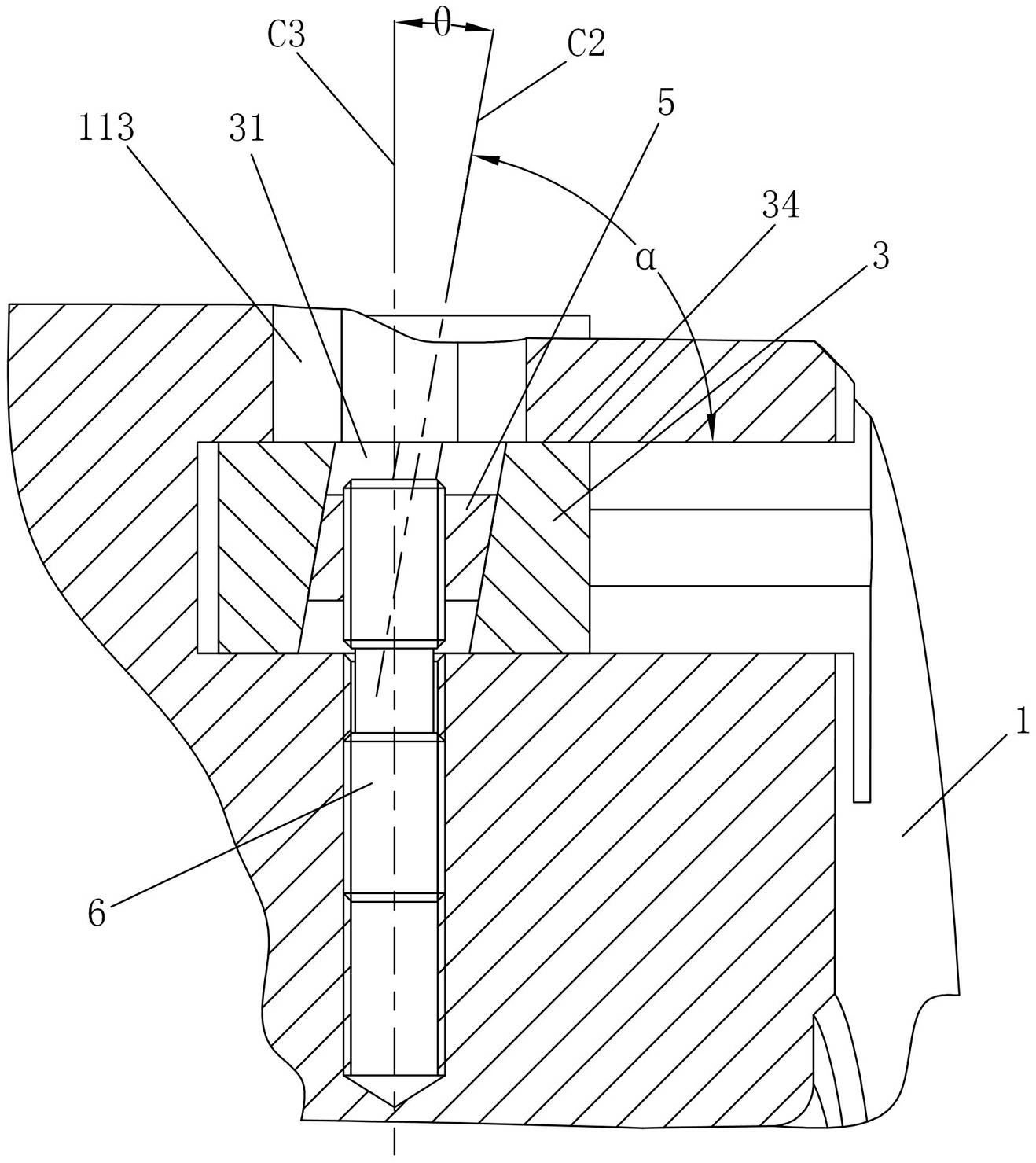

[0029] Figure 1 to Figure 9 An embodiment of an adjustable finishing face milling cutter of the present invention is shown, the milling cutter includes a cutter body 1, a cutting blade 2, an axial positioning block 3 and a locking member 4, and at least one adjustable The accommodating cavity 11 that accommodates the axial positioning block 3, the axial positioning block 3 is slidably arranged in the accommodating cavity 11, the cutting blade 2 is installed on one end of the axial positioning block 3 and fixed by the locking piece 4, and the axial positioning The block 3 is provided with an axial drive hole 31, and the inner wall of the axial drive hole 31 is provided with a pair of oppositely arranged axial positioning surfaces 311, and an adjustment block 5 is slidably arranged in the axial drive hole 31, and the outer wall of the adjustment block 5 is connected to a In close contact with the axial positioning surface 311, the adjustment block 5 is connected to the tool bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com