Full-automatic home roll wire arrangement device for multi-wire cutting machine

A multi-wire cutting machine and wiring device technology, which is applied to fine work devices, work accessories, stone processing equipment, etc., can solve the problems of low wiring automation, high operator requirements, safety accidents, etc., to achieve compact structure, wiring Flexible, adaptable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

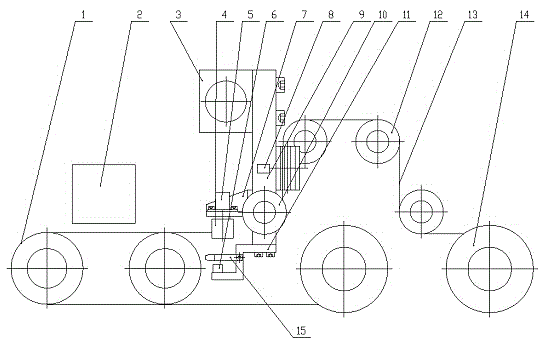

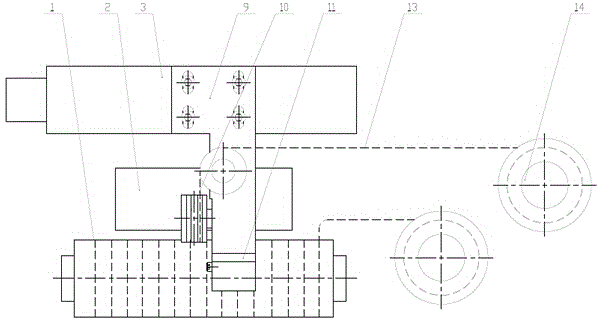

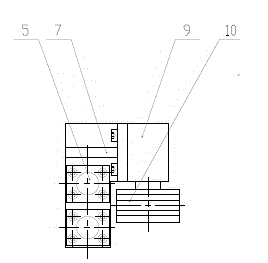

[0011] Such as Figure 1-Figure 3 As shown, an embodiment of the present invention includes a take-up and pay-off spool 14, a guide wheel 12, and a main roller 1; In the groove; the electric linear platform 3 is fixed between the guide wheel 12 and the main roller 1; the electric linear platform 3 is fixedly connected with the top of the fixed plate 9; the lower end of the fixed plate 9 is equipped with a positioning sensor 8 and a winding wire wheel 10; the steel wire 13 is wound in the wire groove of the main roller 1 through the winding wheel 10 after being drawn out from the guide wheel 12; the bottom end of the fixing plate 9 is fixed with an installation block 11; A detection sensor 6 is fixed on the mounting block 11, and the detection sensor 6 and the positioning sensor 8 can all move along the axial direction of the main roller 1 driven by the electric linear platform 3; the detection sensor 6 Close to the main roller 1, and opposite to the slot position of the main ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com