Rapid elevator steel wire rope installing method capable of prolonging service life

An installation method and wire rope technology, applied in the field of elevators, can solve the problems of large physical exertion of staff, increase construction risks, and difficulty in construction, and achieve the effects of reducing safety production risks, prolonging service life, and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

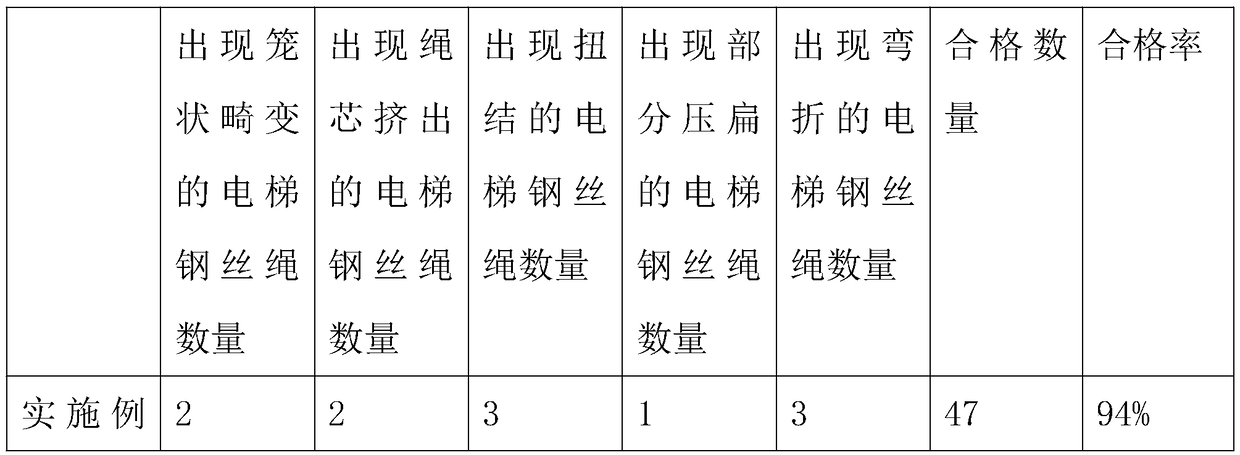

Examples

Embodiment 1

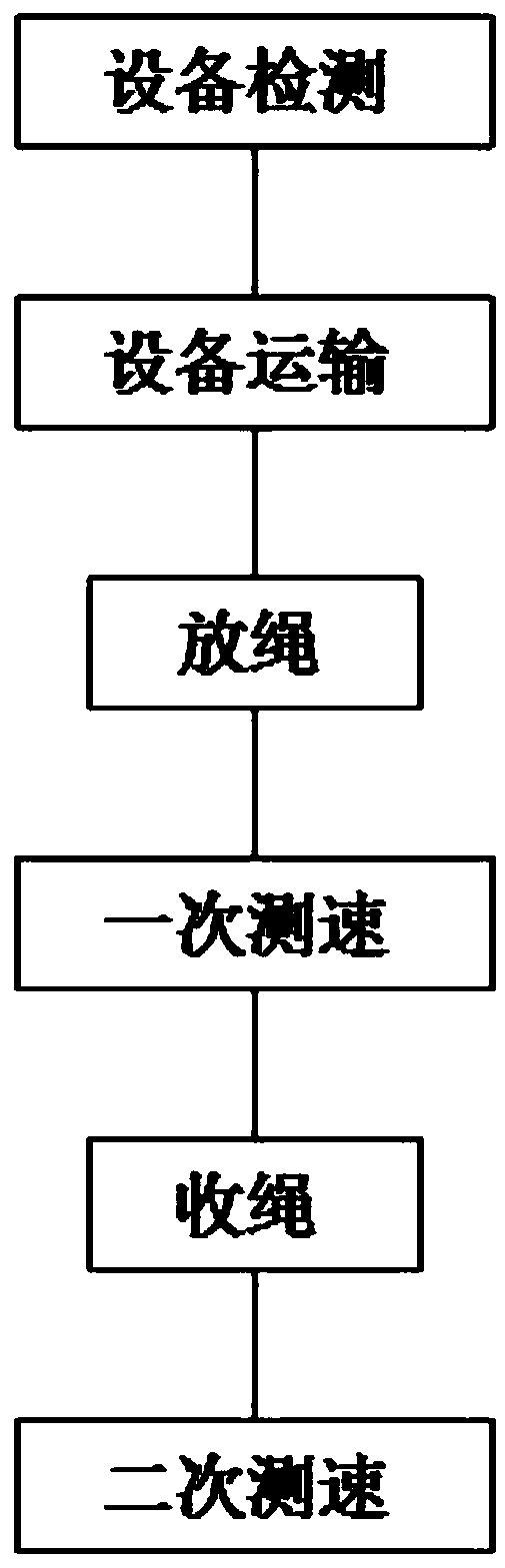

[0021] The present invention provides such figure 1 A fast and service-prolonging elevator wire rope installation method is shown, which specifically includes the following steps:

[0022] Step 1. Equipment inspection: inspect the elevator wire rope by visual inspection, whether there is cage distortion, rope core extrusion, kink, partial flattening and bending, and then use an electronic scale to weigh the elevator wire rope , to detect whether the average mass of the elevator wire rope is greater than or equal to 0.41-0.61 kg per meter;

[0023] Step 2. Equipment transportation: transport the unwound rope reel with elevator wire rope and belt brake installed, the unwound elevator wire rope with servo motor and servo motor drive installed rope reel and hand-held clutch to the elevator machine room Among them, the hand-held clutch includes a cut-off gear and an automatic gear;

[0024] Step 3. Rope release: Pass the end of the elevator wire rope through the hand-held clutch....

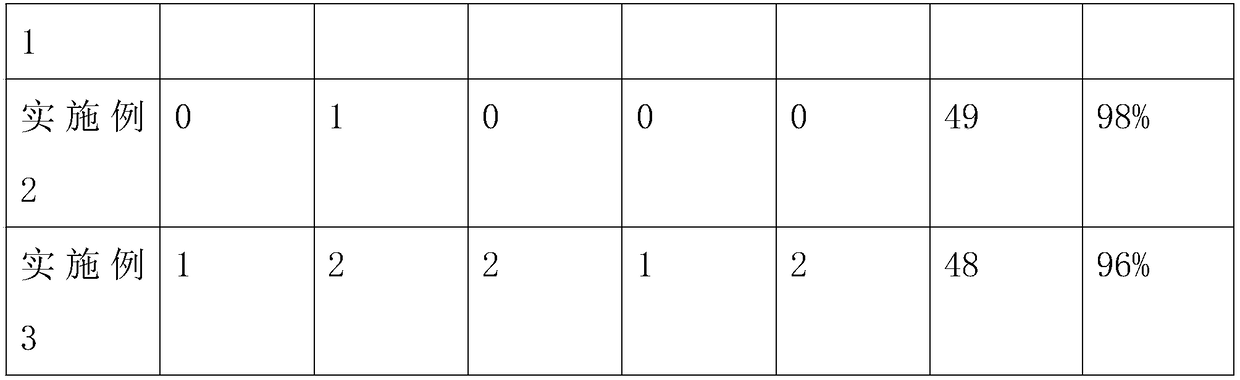

Embodiment 2

[0030] The present invention provides such figure 1 A fast and service-prolonging elevator wire rope installation method is shown, which specifically includes the following steps:

[0031] Step 1. Equipment inspection: inspect the elevator wire rope by visual inspection, whether there is cage distortion, rope core extrusion, kink, partial flattening and bending, and then use an electronic scale to weigh the elevator wire rope , to detect whether the average mass of the elevator wire rope is greater than or equal to 0.51 kg per meter;

[0032] Step 2. Equipment transportation: transport the unwound rope reel with elevator wire rope and belt brake installed, the unwound elevator wire rope with servo motor and servo motor drive installed rope reel and hand-held clutch to the elevator machine room Among them, the hand-held clutch includes a cut-off gear and an automatic gear;

[0033] Step 3. Rope release: Pass the end of the elevator wire rope through the hand-held clutch. At t...

Embodiment 3

[0039] The present invention provides such figure 1 A fast and service-prolonging elevator wire rope installation method is shown, which specifically includes the following steps:

[0040] Step 1. Equipment inspection: inspect the elevator wire rope by visual inspection, whether there is cage distortion, rope core extrusion, kink, partial flattening and bending, and then use an electronic scale to weigh the elevator wire rope , to detect whether the average mass of the elevator wire rope is greater than or equal to 0.61 kg per meter;

[0041] Step 2. Equipment transportation: transport the unwound rope reel with elevator wire rope and belt brake installed, the unwound elevator wire rope with servo motor and servo motor drive installed rope reel and hand-held clutch to the elevator machine room Among them, the hand-held clutch includes a cut-off gear and an automatic gear;

[0042] Step 3. Rope release: Pass the end of the elevator wire rope through the hand-held clutch. At t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com