Conveyor belt tensioning device and belt conveyor

A belt conveyor and tensioning device technology, applied in conveyors, conveyor objects, conveyor control devices, etc., can solve problems such as shortening the service life of stressed components, affecting material conveying efficiency, and improving equipment durability. , to meet the normal operation, the effect of low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

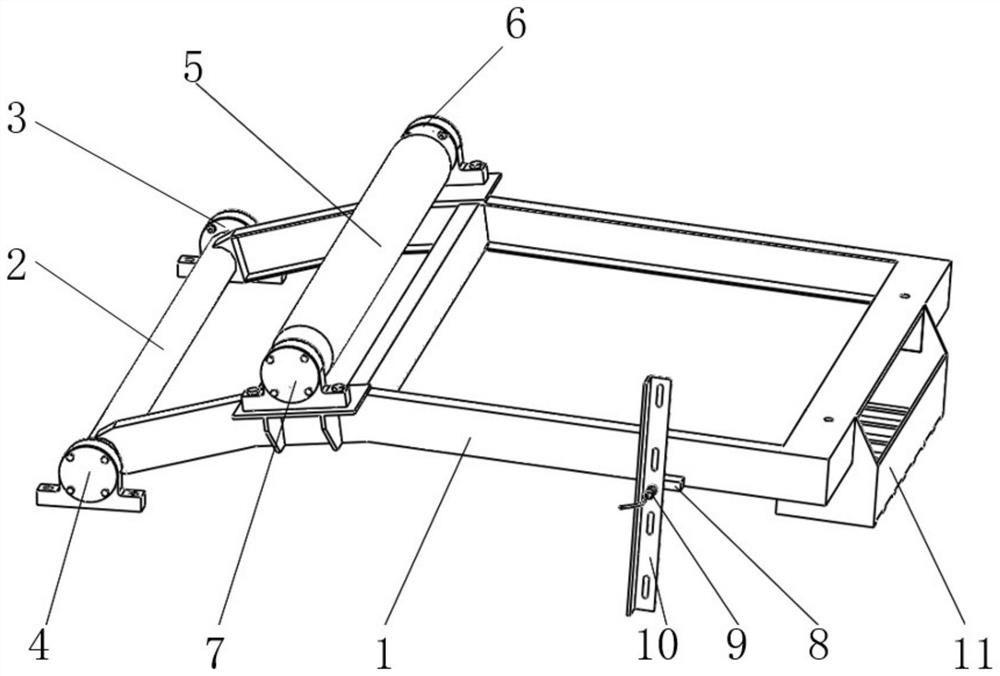

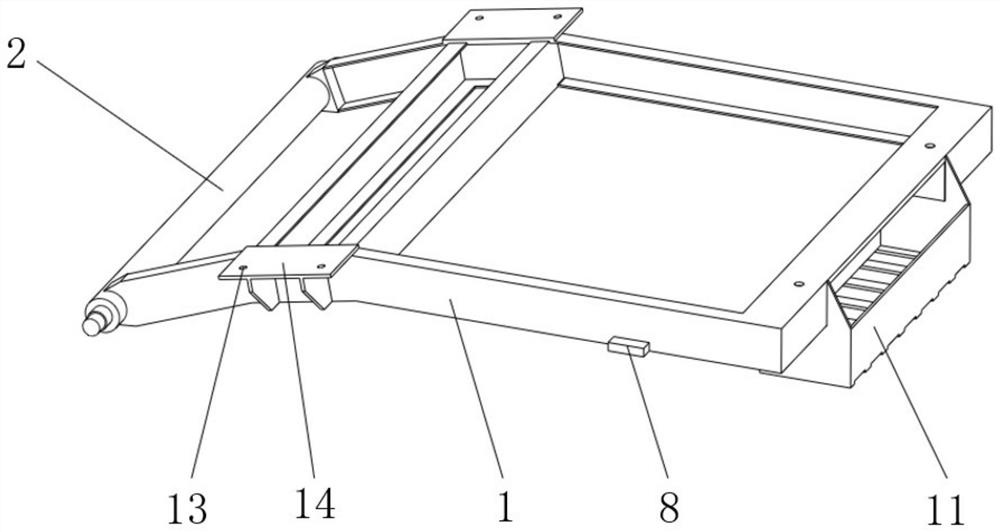

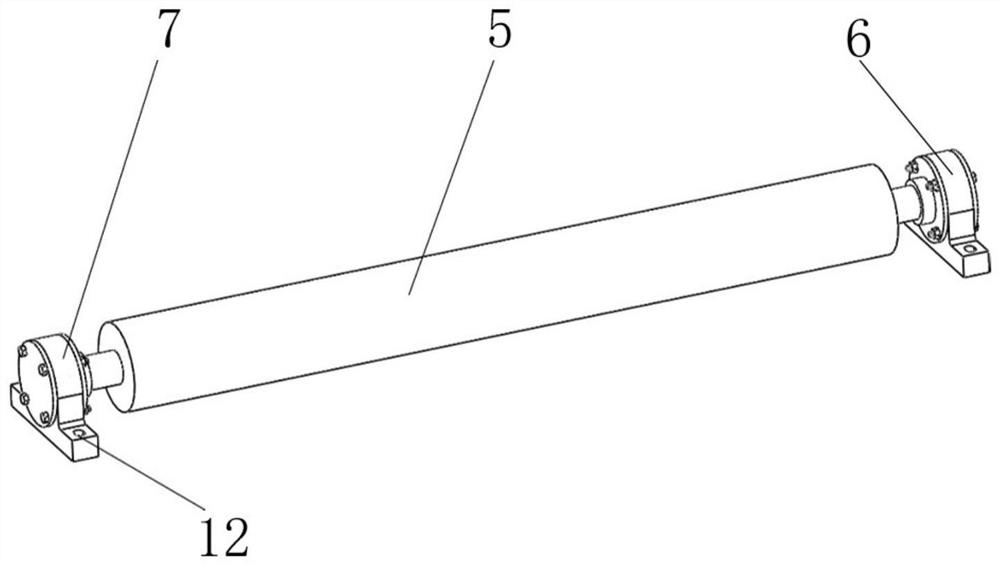

[0037] A conveyor belt tensioner for tensioning the conveyor belt of a belt conveyor such as Figure 1~4 As shown, it includes a rotating assembly, a main frame 1, a conveyor belt pressing assembly, a weight assembly, and a sensor assembly. The rotating assembly is installed on one end of the main frame 1, and the weight assembly is installed on the other end of the main frame 1. The conveyor belt pressing assembly is arranged on the middle top surface of the main frame 1 . When in use, the conveyor belt tensioning device is set on the belt conveyor, the main frame 1 is rotatably connected with the frame of the belt conveyor through the rotating assembly, and the return part of the conveyor belt of the belt conveyor passes through the conveyor belt and is compressed Components, the hammer component drives the main frame 1 and the conveyor belt pressing component to press down to complete the self-adaptive tensioning of the conveyor belt, adjust the tension of the conveyor belt...

Embodiment 2

[0046] A belt conveyor, including a conveyor belt tensioning device described in Embodiment 1, the conveyor belt tensioning device is rotatably connected to the frame of the belt conveyor through a rotating assembly, and the conveyor belt of the belt conveyor The return part of the belt passes through the conveyor belt compression assembly, and the weight assembly drives the main frame 1 to rotate and drives the conveyor belt compression assembly to press and tension the conveyor belt.

[0047] Specifically, the present invention can be set at the return part of the conveyor belt of the belt conveyor. As in this embodiment, the conveyor belt tensioning device is arranged at the rear of the driving roller of the belt conveyor to tighten the transmission. The elongation of the conveyor belt when the roller is dragging the conveyor belt.

[0048] In this example, if Figure 7 Shown is an existing belt conveyor structure, which includes a head drop coal hopper 18 set at the head,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com