Gas phase medium gasifying nozzle and using method

A technology of gasification medium and gas phase, which is applied in the direction of chemical methods, chemical instruments and methods, and combustion methods for reacting gas medium and gas medium, and can solve problems such as obstruction of gasification substances and unfavorable gasification of gasification substances, and achieve Satisfy the effect of long period, solve the short service life and prolong the operation life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with the preferred embodiment shown in accompanying drawing, be described in further detail:

[0020] Below by embodiment the present invention is described in further detail, but the present invention is not limited to embodiment:

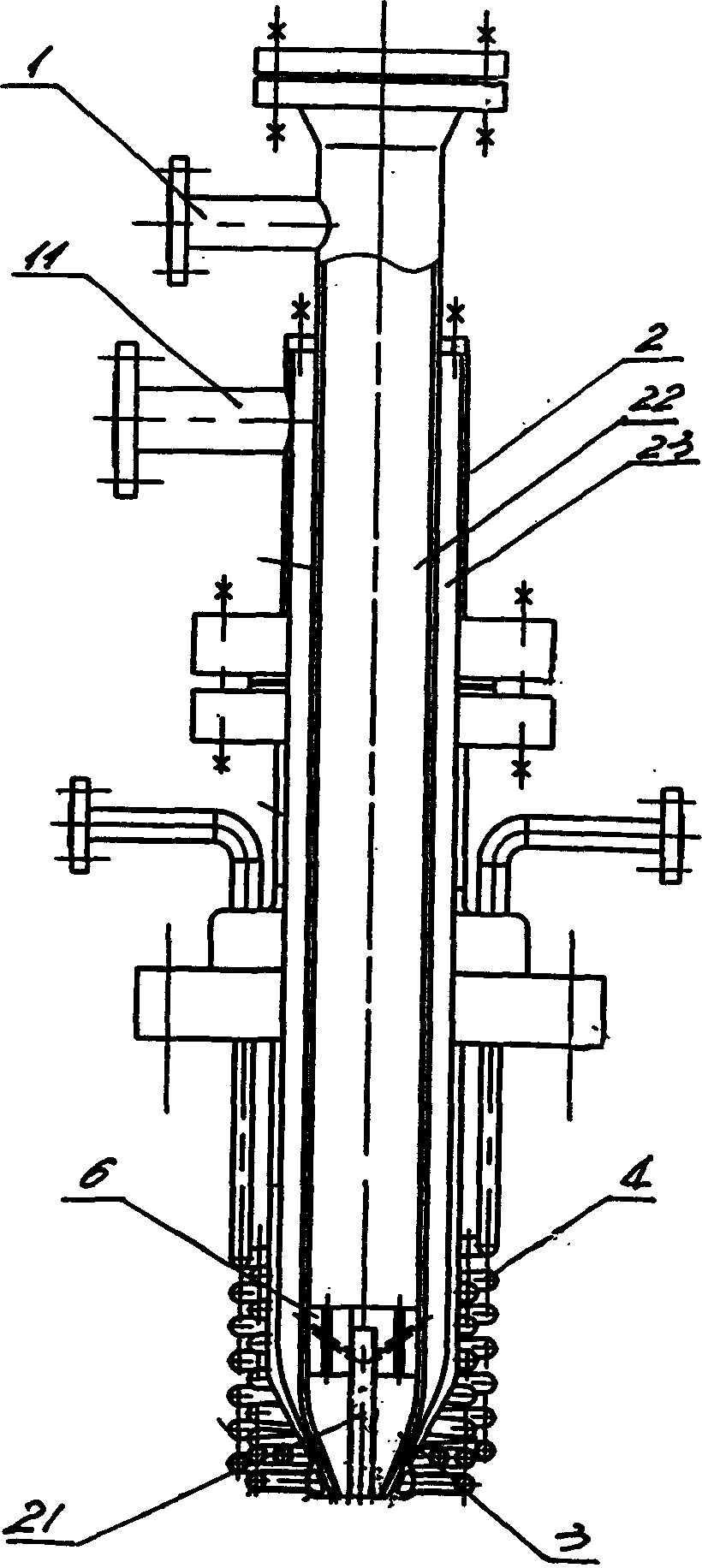

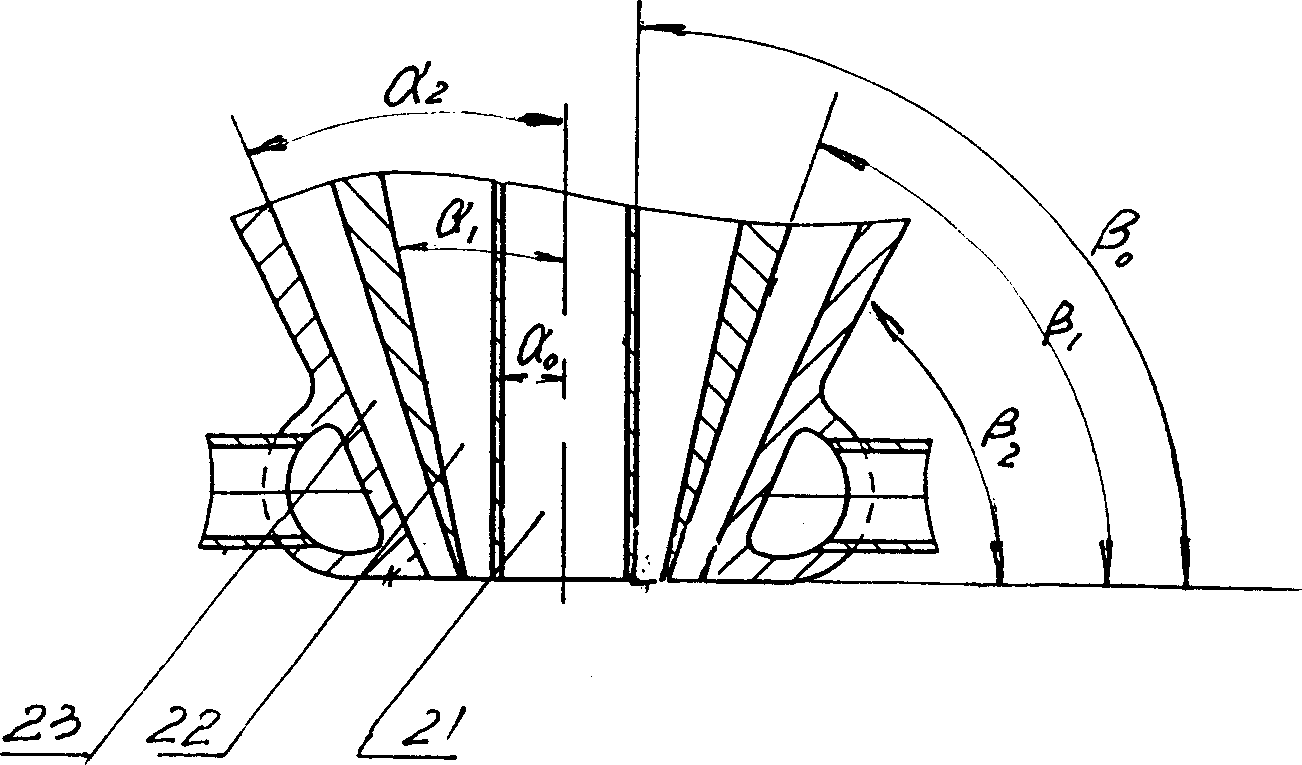

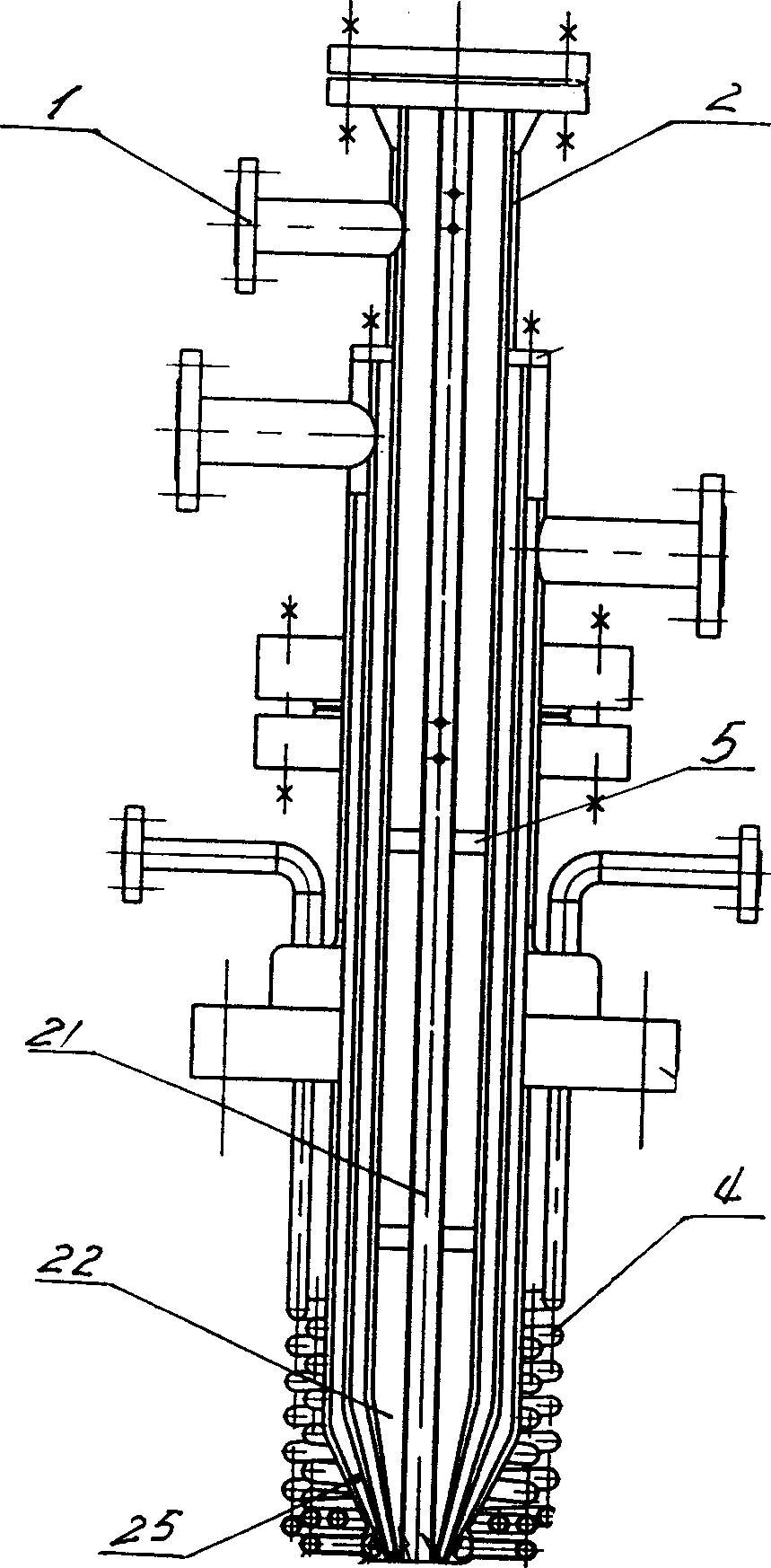

[0021] See figure 1 , figure 2 , Invention Example 1 Three-channel gas-phase medium gasification nozzle, the gasification medium inlet pipe 1 with a flange is fixedly connected to the corresponding multi-channel nozzle 2, the nozzle 3 and the nozzle 2 are fixed or integrated, Nozzle 3 and nozzle 2 are fixedly connected with equal wall thickness, and the transition is smooth; the inner and outer walls of the nozzle are tapered, and the wall thickness is uniformly thinned by a straight line, which is trapezoidal; the wall thickness of the nozzle at the end of nozzle 3 is 1~ 4mm. Nozzle 3 is made of high temperature resistant alloy material INCONEL600. The water cooling coil 4 is made of HASTELLOY high temperature res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com