Organic luminescent device containing coloured neutral dopant in hole transfer layer and/or electronic transfer layer

A technology of organic light-emitting devices and hole transfer, which is applied in the fields of electric solid-state devices, electroluminescent light sources, semiconductor/solid-state device manufacturing, etc., which can solve the problems of changing the electroluminescent color of devices, and achieve high luminous efficiency and long operating life , the effect of excellent brightness performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

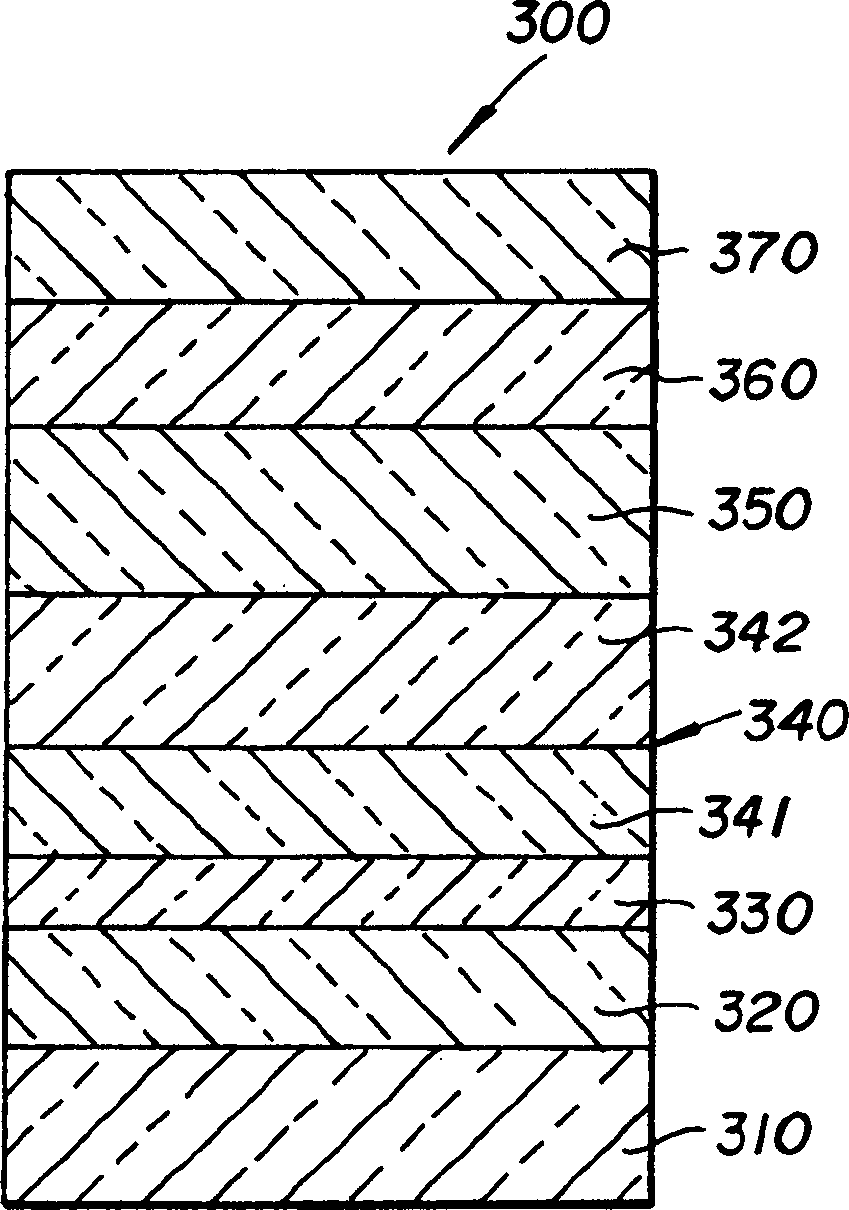

[0075] use as image 3 The structure shown, constructs the OLED of the present invention. The hole transport layer (340) consists of a 120nm undoped NPB sublayer (341) and a 30nm NPB sublayer (342) doped with ADN as a color-neutral dopant, ADN accounting for 5% of the sublayer . In all other respects, the structure and construction of this device was the same as that of the OLED of Comparative Example 1. The initial luminous efficiency, CIE coordinate value, and driving voltage are also shown in Table I. The relative luminance and drive voltage as a function of operating time are also shown in Image 6 with 7 middle. Example 3

Embodiment 3

[0076] use as Figure 4 The structure shown, constructs the OLED of the present invention. The electron transport layer (460) consists of a 20nm Alq sublayer (461) doped with ADN as a color-neutral dopant, ADN accounting for 5% of the layer, and a 15nm undoped Alq sublayer (462) . In all other respects, the structure and construction of this device was the same as that of the OLED of Comparative Example 1. The initial luminous efficiency, CIE coordinate value, and driving voltage are also shown in Table I. The relative luminance and drive voltage as a function of operating time are also shown in Image 6 with 7 middle. Example 4

Embodiment 4

[0077] use as Figure 5 The structure shown, constructs the OLED of the present invention. The hole transport layer (540) consists of a 120nm undoped NPB sublayer (541) and a 30nm NPB sublayer (542) doped with ADN as a color-neutral dopant, ADN accounting for 5% of the sublayer . The electron transport layer (560) consists of a 20nm Alq sublayer (561) doped with ADN as a color-neutral dopant, ADN accounting for 5% of the layer, and a 15nm undoped Alq sublayer (562) . In all other respects, the structure and construction of this device was the same as that of the OLED of Comparative Example 1. The initial luminous efficiency, CIE coordinate value, and driving voltage are also shown in Table I. The relative luminance and drive voltage as a function of operating time are also shown in Image 6 with 7 middle.

[0078] Example

[0079] exist Image 6 with 7 In , the stitch corresponding to the corresponding embodiment is identified by the number to the right of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com