Hydraulic impactor driven by spiral impeller

A technology of hydraulic impactor and helical impeller, which is applied in the field of oil drilling, can solve the problems of short life of impactor and small single impact force, and achieve the effects of stable working performance, large impact force, and easy use and promotion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

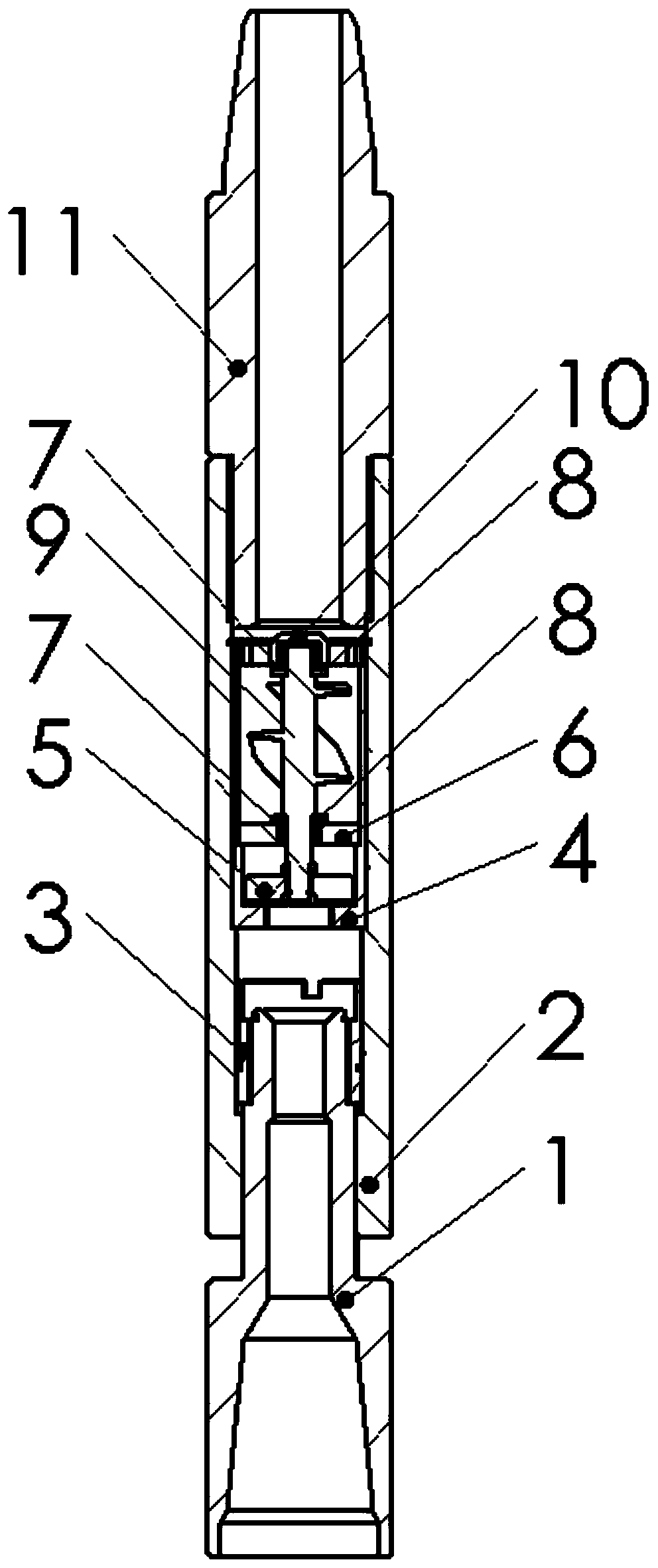

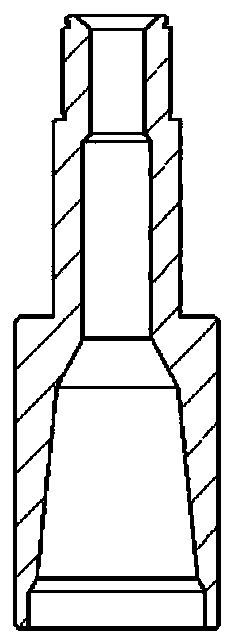

[0052] Such as Figure 1-16 As shown, a hydraulic impactor driven by a helical impeller provided in this embodiment includes a transmission short 1, a screw lock 3, an impact chamber 2, a rectifier 4, an impeller shaft 9, and an impactor main body 11;

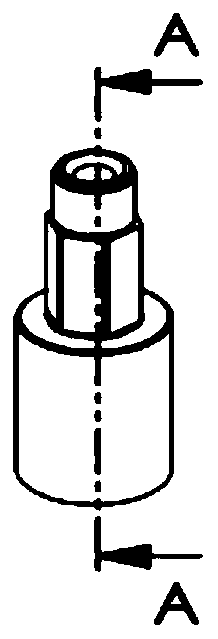

[0053] The rectifier 4 is a hollow cylindrical structure, and one end of the rectifier 4 is open, and the other end is provided with a closed plate 401, and the closed plate 401 is provided with a through discharge hole 402 and a main channel 403; the impeller shaft 9 An impeller 901 is arranged on it, and an upper fixed plate 10 and a lower fixed plate 6 are respectively arranged on the impeller shaft 9 above and below the impeller 901. The end of the impeller shaft 9 is provided with a transmission plate 5, and the upper fixed plate 10 and the lower fixed plate 6 are provided with a flow port 12, and the transmission plate 5 is provided with a flow hole 501; the impeller shaft 9 is located in the rectifier 4, and the transmis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com