Pole disc type multi-boom drill jumbo

A technology of rock drilling rigs and pole discs, which is applied to drilling equipment, drilling equipment and methods, and earthwork drilling and production, and can solve problems such as slow drilling positioning speed, low operating efficiency, and slow project progress, and achieve a reduction in drilling The effect of reducing the time for hole positioning, improving work efficiency, and saving positioning time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in combination with specific embodiments.

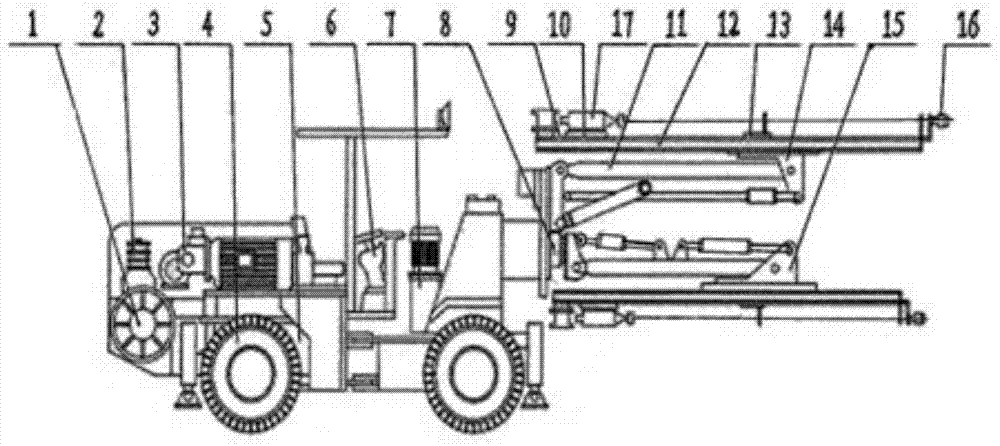

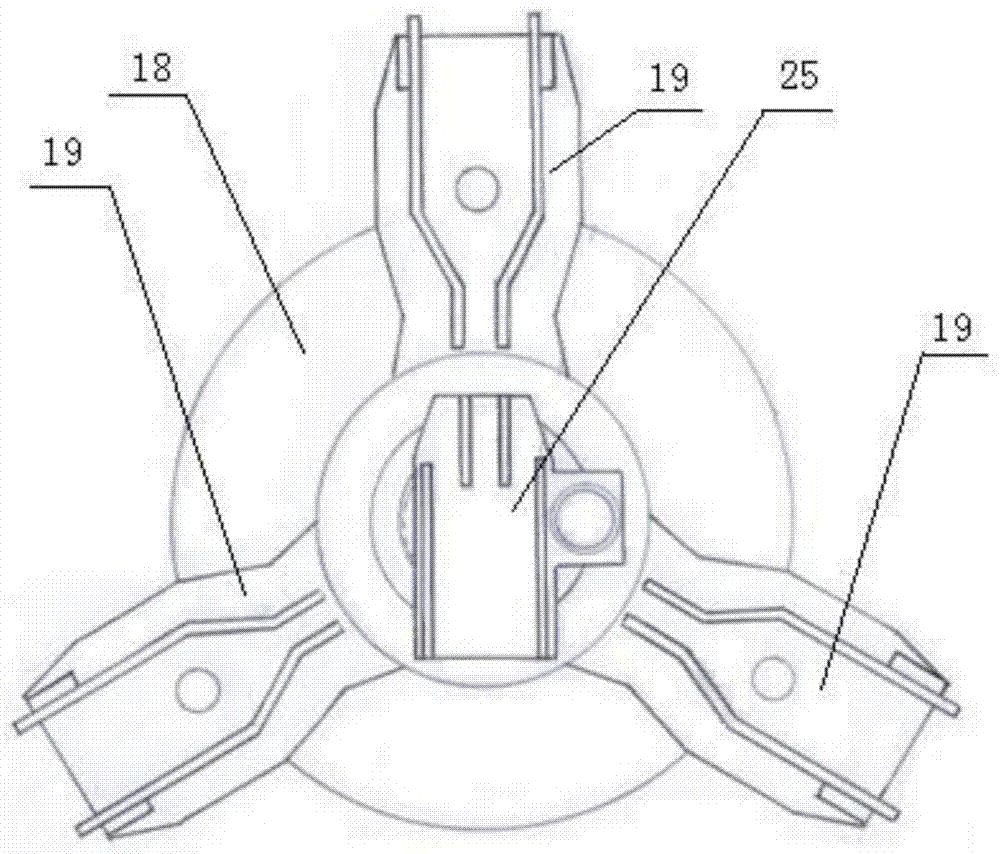

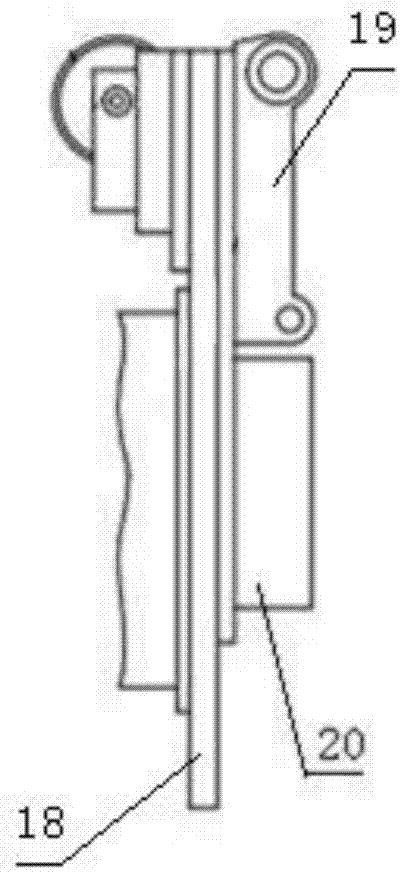

[0025] Such as figure 1 As shown, a pole plate multi-arm rock drilling jumbo includes a chassis traveling mechanism 4, a frame, an engine, a hydraulic system 3, a cooling system, an electrical system, a slag cleaning system, an operating system 6, a pole plate mechanism 8, A plurality of main boom assemblies, propelling beam assemblies and rock drilling machines 17, the frame is arranged on the chassis traveling mechanism 4, the frame includes a front frame and a rear frame, the front frame and the rear frame are hingedly connected, and the rear frame An engine, a hydraulic system 3, a cooling system, an electrical system, a slag cleaning system and an operating system 6 are installed, a pole plate mechanism 8 is installed on the front frame, and a plurality of main arm assemblies are installed on the pole plate mechanism 8, and the main arm assembly A propelling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com