Extra-large karst cave bottom treatment construction method

A construction method and technology for karst caves, which are applied in the fields of earthwork drilling, infrastructure engineering, soil protection, etc., can solve the problem that the reinforcement construction method cannot be applied to extra-large karst caves, and achieve the effects of improving work efficiency, saving time and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045]The specific embodiment of the present invention will be further described in conjunction with the accompanying drawings.

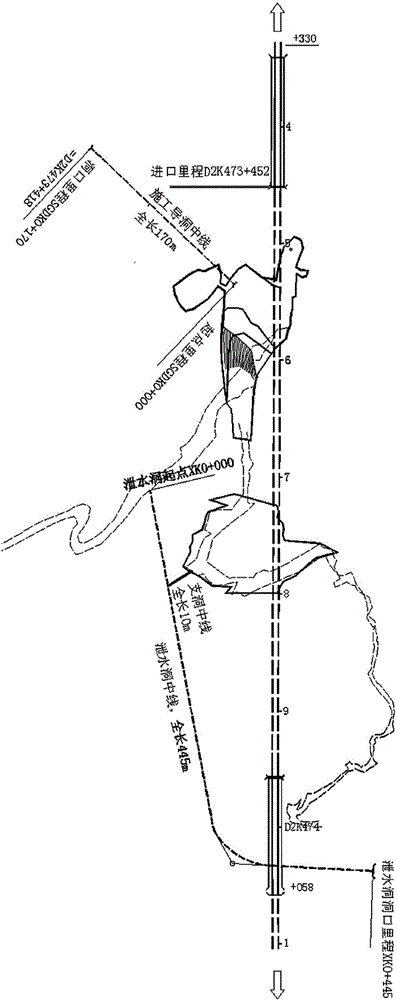

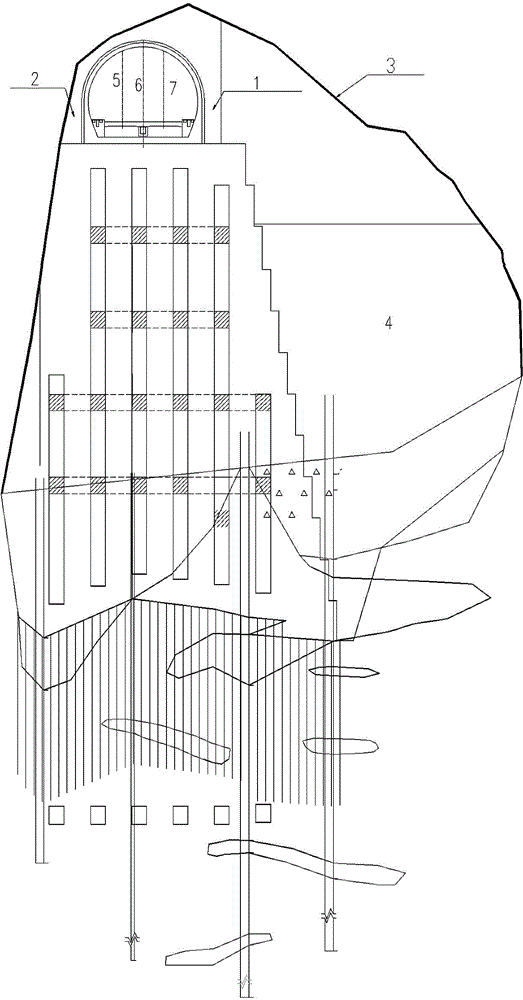

[0046] General situation of the tunnel cave: According to the change design of a certain tunnel, the karst cavity section of D2K473+505~+585 adopts the full masonry backfill scheme, and the bottom of the cave is supplemented by drilling. There are beaded filling caves at the bottom of the cave, and small empty cave. The specific treatment plan is as follows:

[0047] The tunnel bottom of section D2K473+505~+585 is basically in the dissolution cavity, and the bottom of the tunnel in this section is backfilled by masonry; the collapse of the wall of the solution cavity in section D2K473+565~+585 affects the safety of the tunnel lining structure, and the masonry backfill surface and the hole The wall cavity is backfilled with waste ballast. Before backfilling, the gravel soil at the bottom of the solution cavity should be removed. Among them, D2K473...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com