Cold-extrusion forming process of high-temperature alloy high-strength skirt type self-locking hexagonal nut

A technology of high-temperature alloy and forming process, which is applied in the field of precision forging, can solve problems such as easily damaged tools, and achieve the effects of increasing service life, improving fatigue resistance, and improving toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

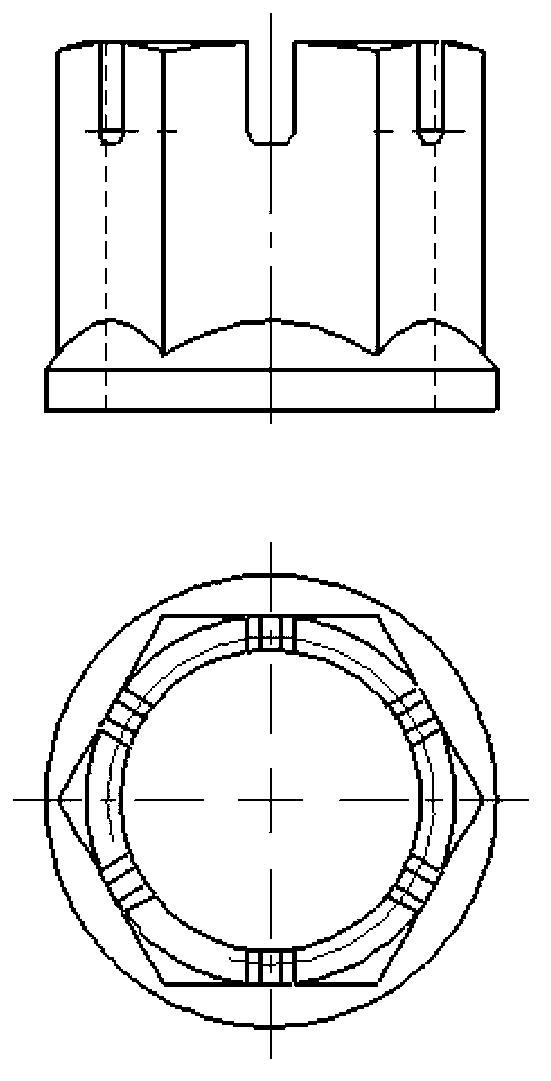

[0027] Take the MJ24X2 skirt-type self-locking hexagonal nut as an example: use Φ35mm bar stock, and cut the bar into 16±0.1mm bar sections. Machining is done first by turning one end face to the light, turning the car parallel to the other end to determine the total length, turning the length of the control rod section on the other end face to 15±0.1mm, turning the outer circle to Φ34.2+0.15mm, and turning a C2 angle. Put the machined billet into the shot blasting machine as a whole for shot blasting, and then coat the entire surface of the billet with lubricant. Among them, the lubricant is a830 lubricating oil produced by Jiashiduo Company.

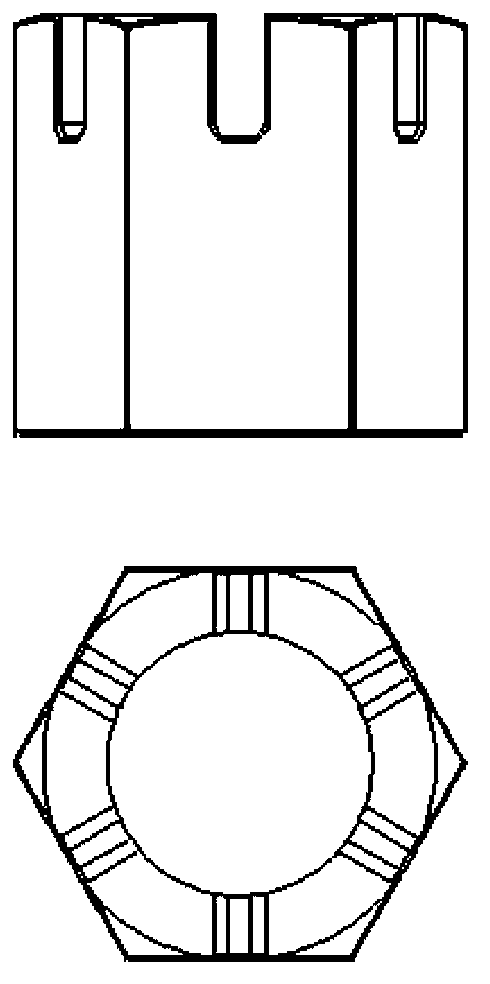

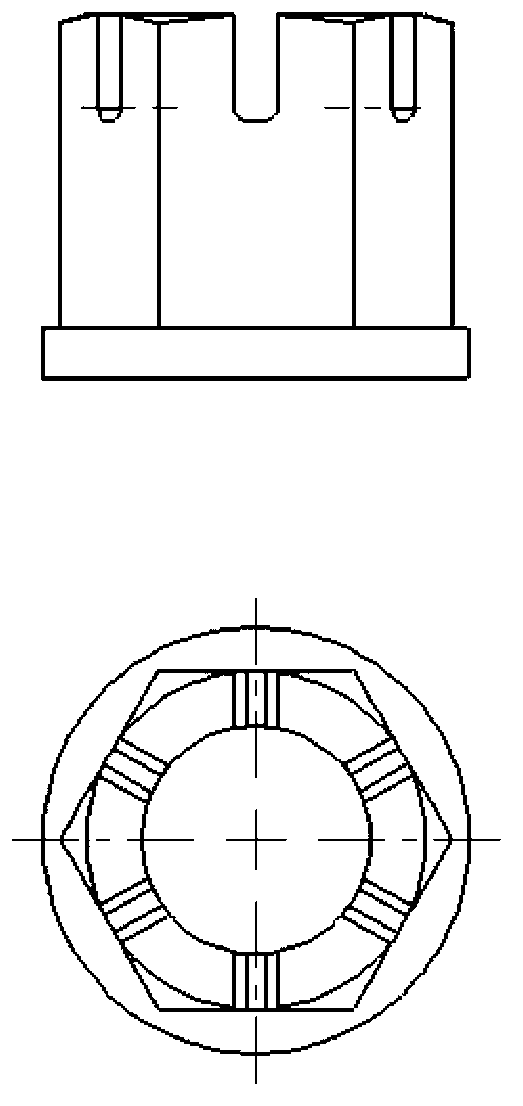

[0028] combine image 3 , Figure 4 and Figure 5 After the above-mentioned treatment, the billet is cold-extruded in the cavity of the cold-extrusion molding die, and formed into a skirt with a short cylindrical straight step and a 45° conical skirt, the end face of the skirt with a concave center blind hole, an outer hexahedron an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com