Hydro-hammer

A technology of hydraulic impactor and impact seat, which is applied to the driving device for drilling in the borehole, drilling equipment, earthwork drilling and production, etc. It can solve the problems of not being able to meet the requirements of rapid drilling, affecting the working efficiency of the drill bit, and poor drillability. Achieve the effect of improving downhole operation efficiency, shortening drilling time and saving drilling cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The main idea of the present invention is to install the tool on the bottom hole assembly during drilling operations, and use high-pressure liquid as power to realize the reciprocating motion of the hammer head so that the impact load acts on the drill bit to achieve rotation and impact compound rock formation. Through the following description of the embodiments, it will be more helpful for the public to understand the present invention, but the specific embodiments given by the applicant cannot and should not be regarded as limitations on the technical solutions of the present invention, any components or technical features Changes to the definition and / or formal but not substantive changes to the overall structure should be regarded as the scope of protection defined by the technical solutions of the present invention.

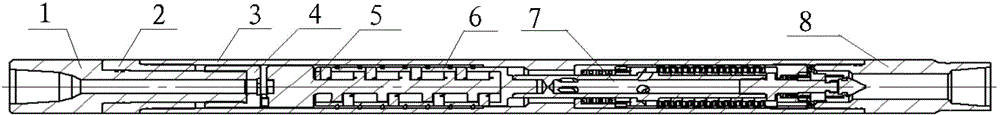

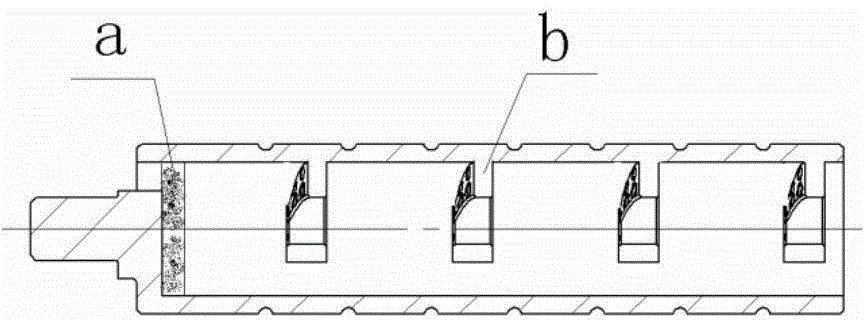

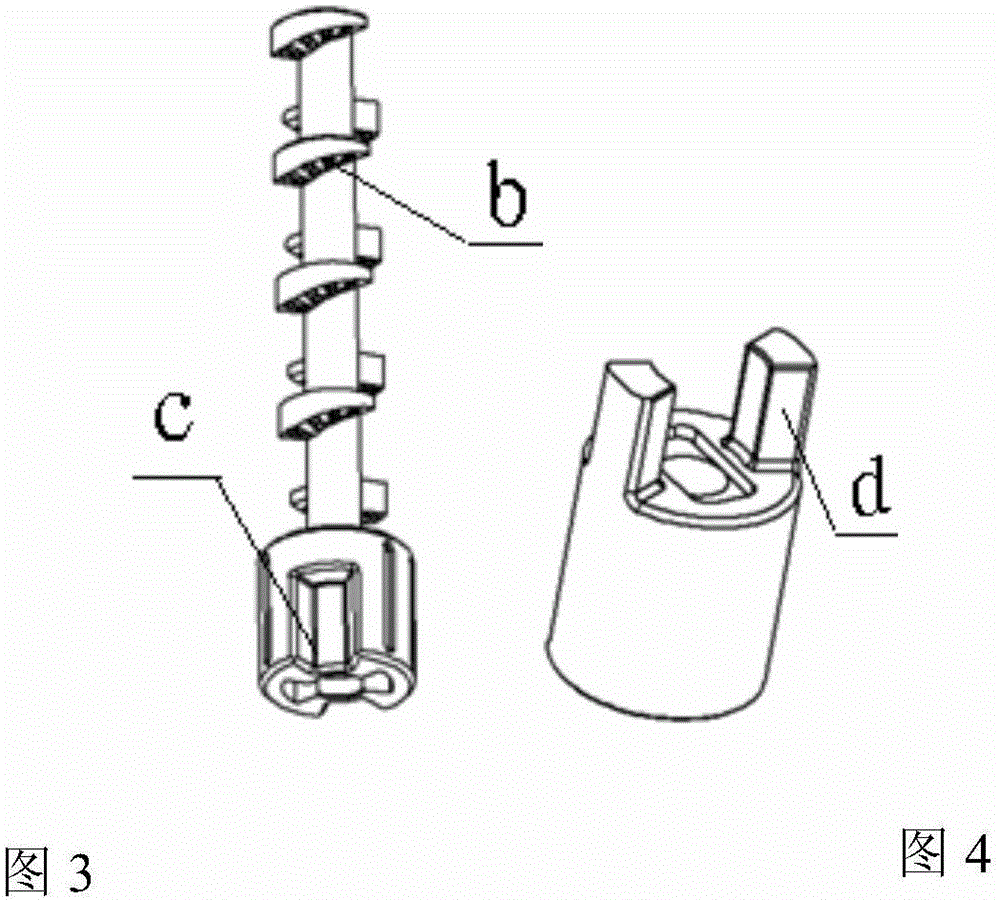

[0020] Such as Figure 1 to Figure 4 The hydraulic impactor shown includes an impact seat 1, a transmission sleeve 2, a casing 3, a guide sleeve 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com