While-drilling micro-bore-enlarging well wall trimming tool and using method thereof

A dressing tool, while drilling technology, applied in drilling equipment and methods, drilling equipment, drill bits, etc., can solve the problems of irregular wellbore, wear of stabilizers, poor drillability, etc., to reduce workload and save drilling time , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of the present invention will be described in detail below with reference to the drawings and specific implementations.

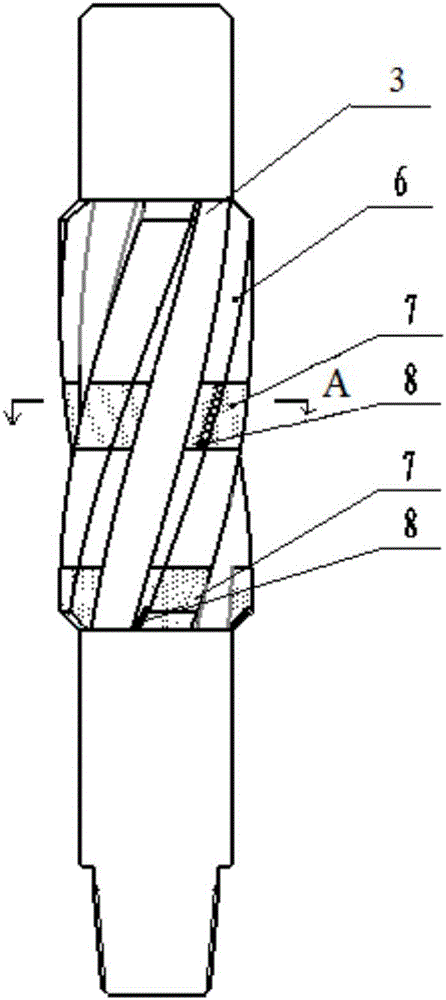

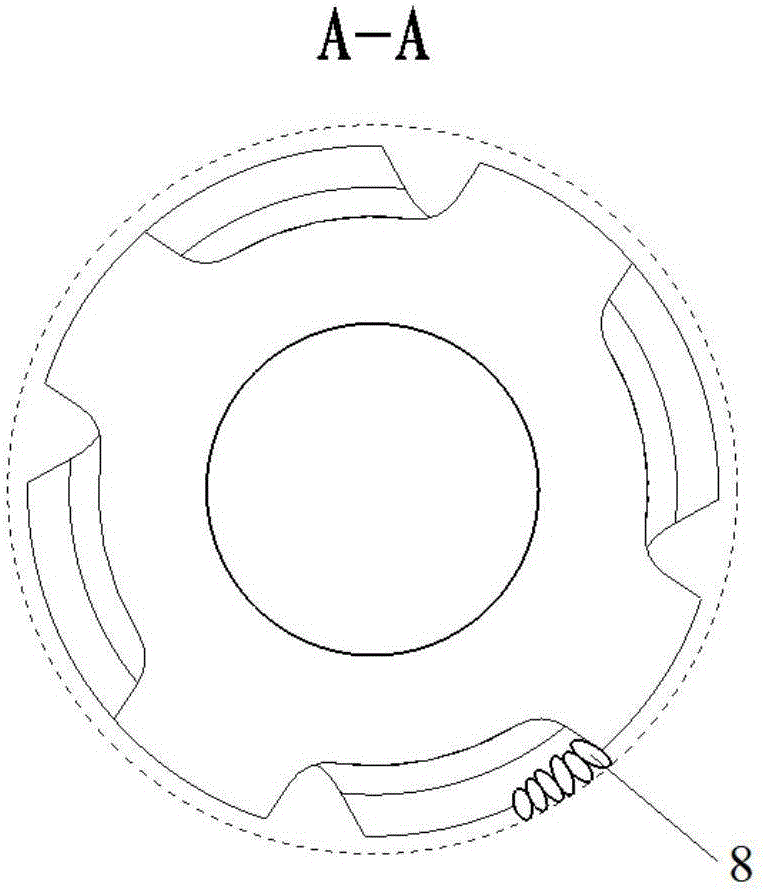

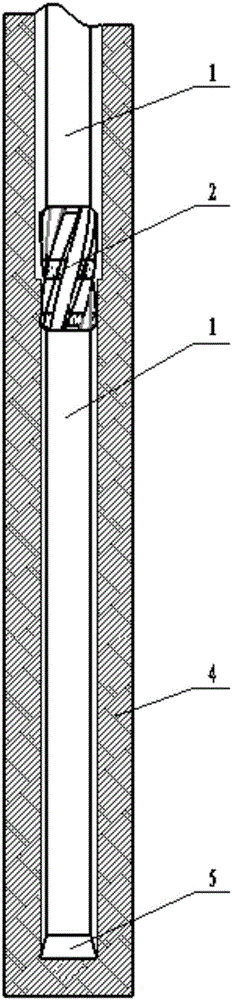

[0018] Such as figure 1 , 2 As shown, a micro-reaming while drilling well wall dressing tool includes a cylindrical body 3, a centralizing belt 6 and cutting teeth 8 arranged on the surface of the cylindrical body; the cylindrical body 3 can be connected to the drill collar 1 , It rotates with the rotation of the drill collar 1; there are multiple centralizing belts 6 parallel to each other, and each centralizing belt 6 is spirally protruding on the surface of the body 3; the helix angle of the centralizing belt 6 is 20-40°; The upper and lower ends of the centralizing belt 6 and the main body are arc-shaped transitions; the bottoms of multiple centralizing belts 6 are all provided with a cemented carbide layer 7, and at the same time, one of the centralizing belts 6 is provided with a cemented carbide layer 7 in the longitudinal d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com