Patents

Literature

43results about How to "Stable gas pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

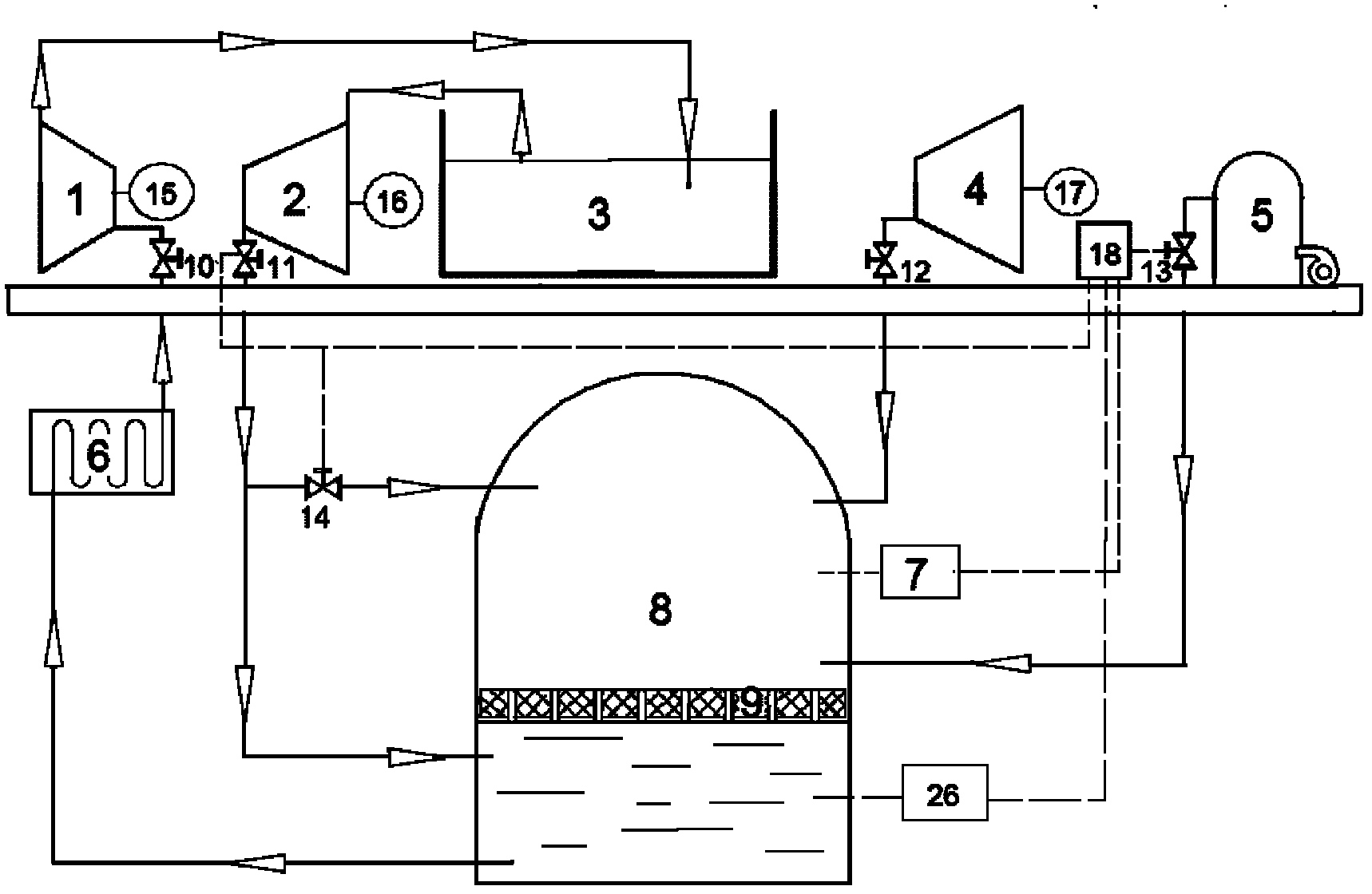

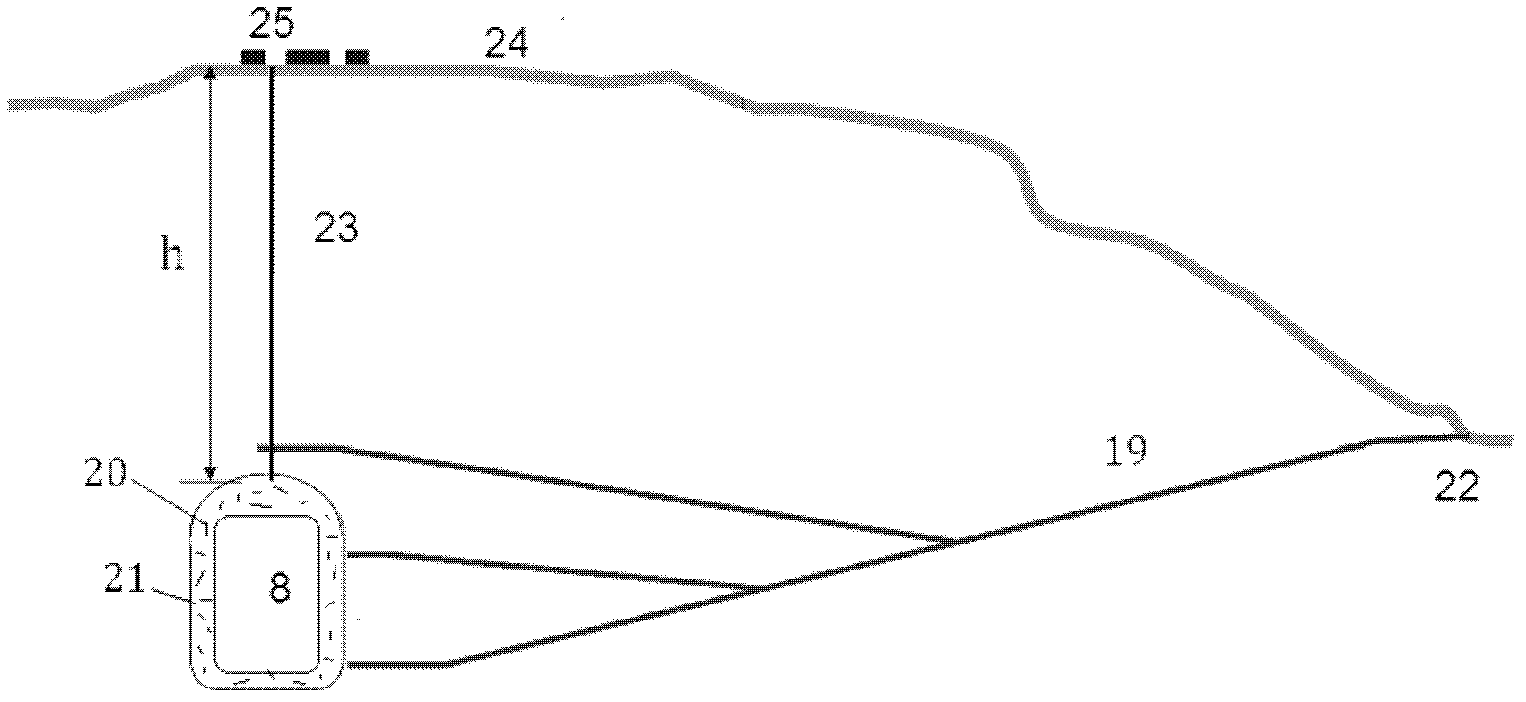

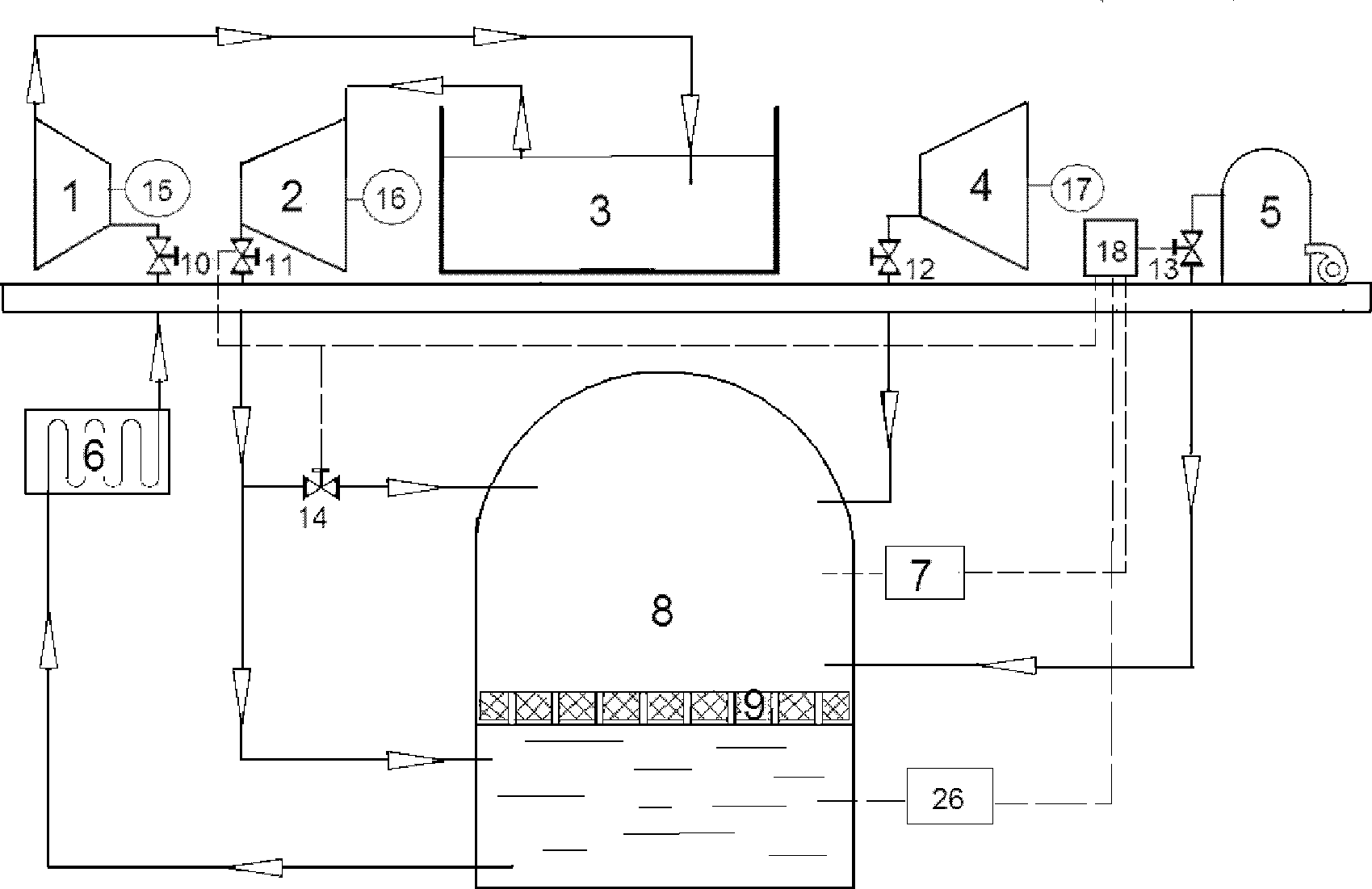

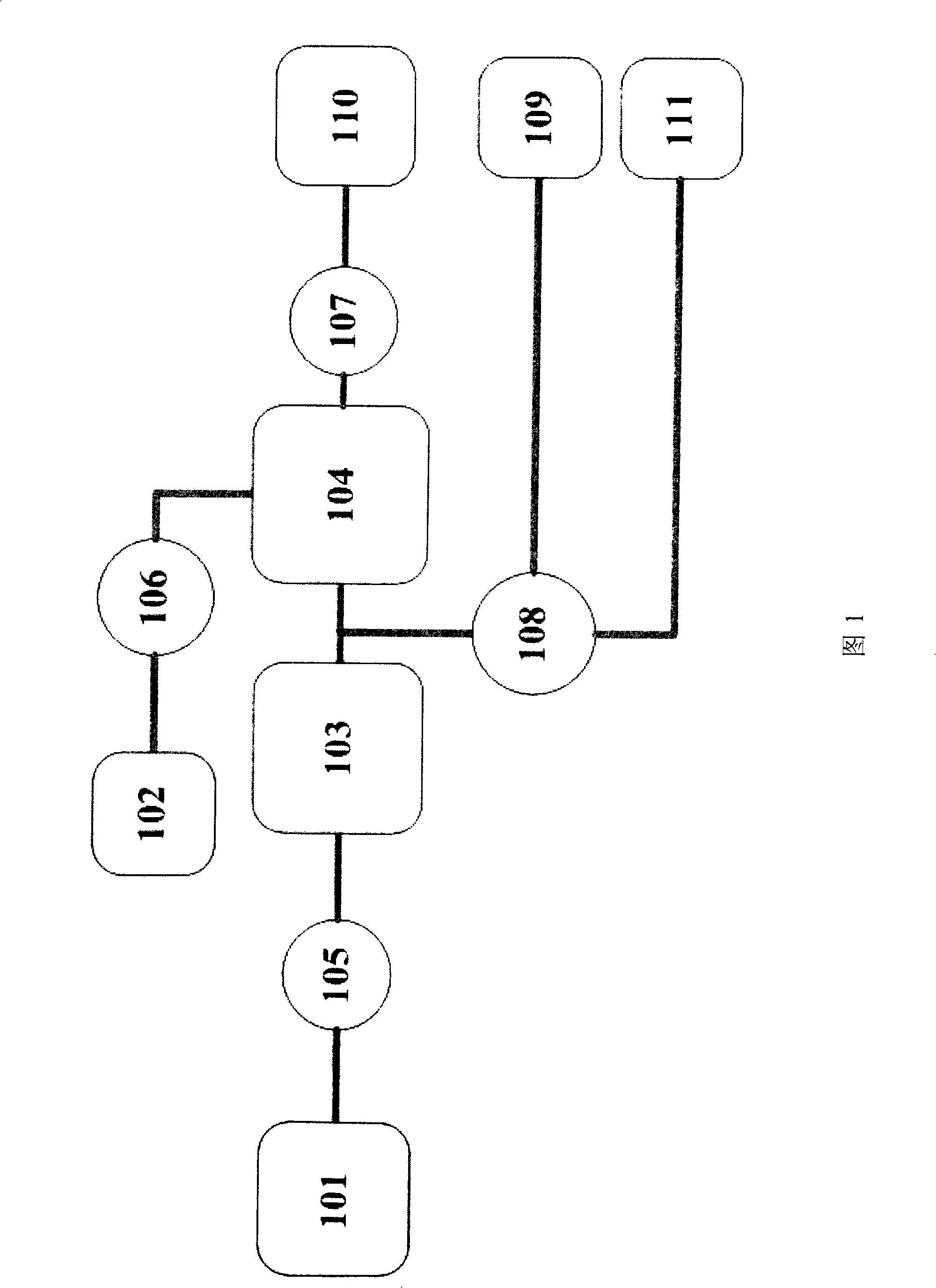

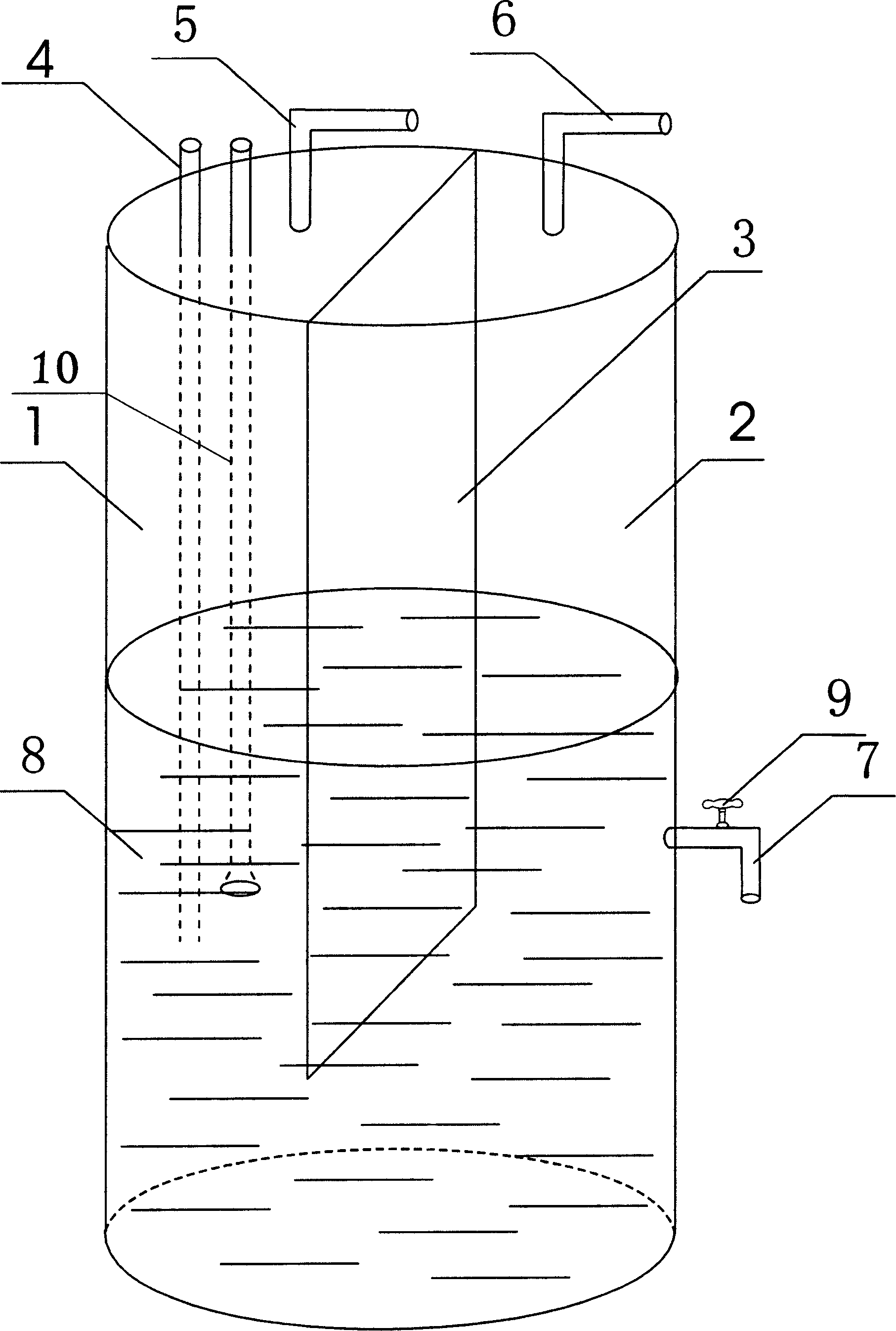

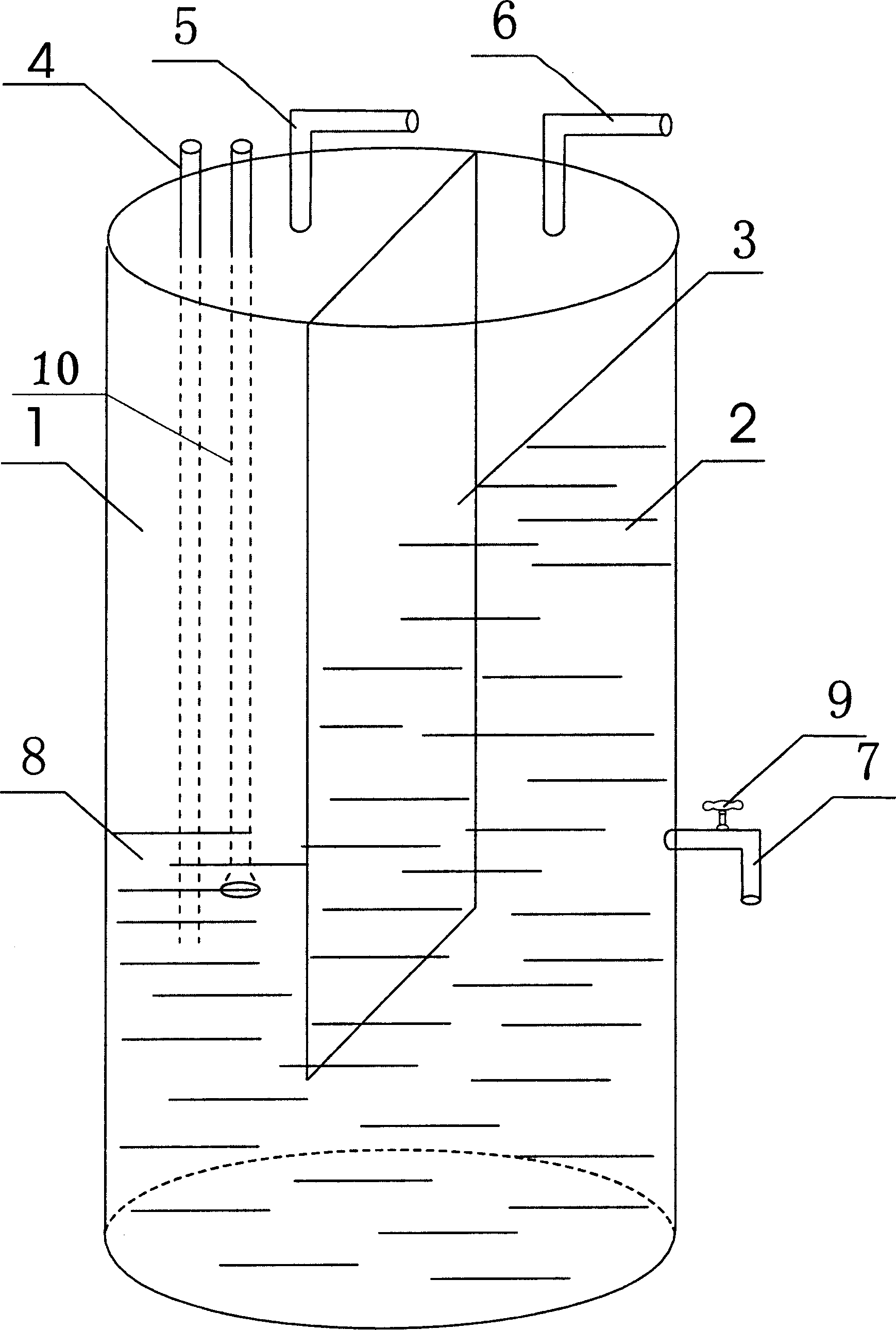

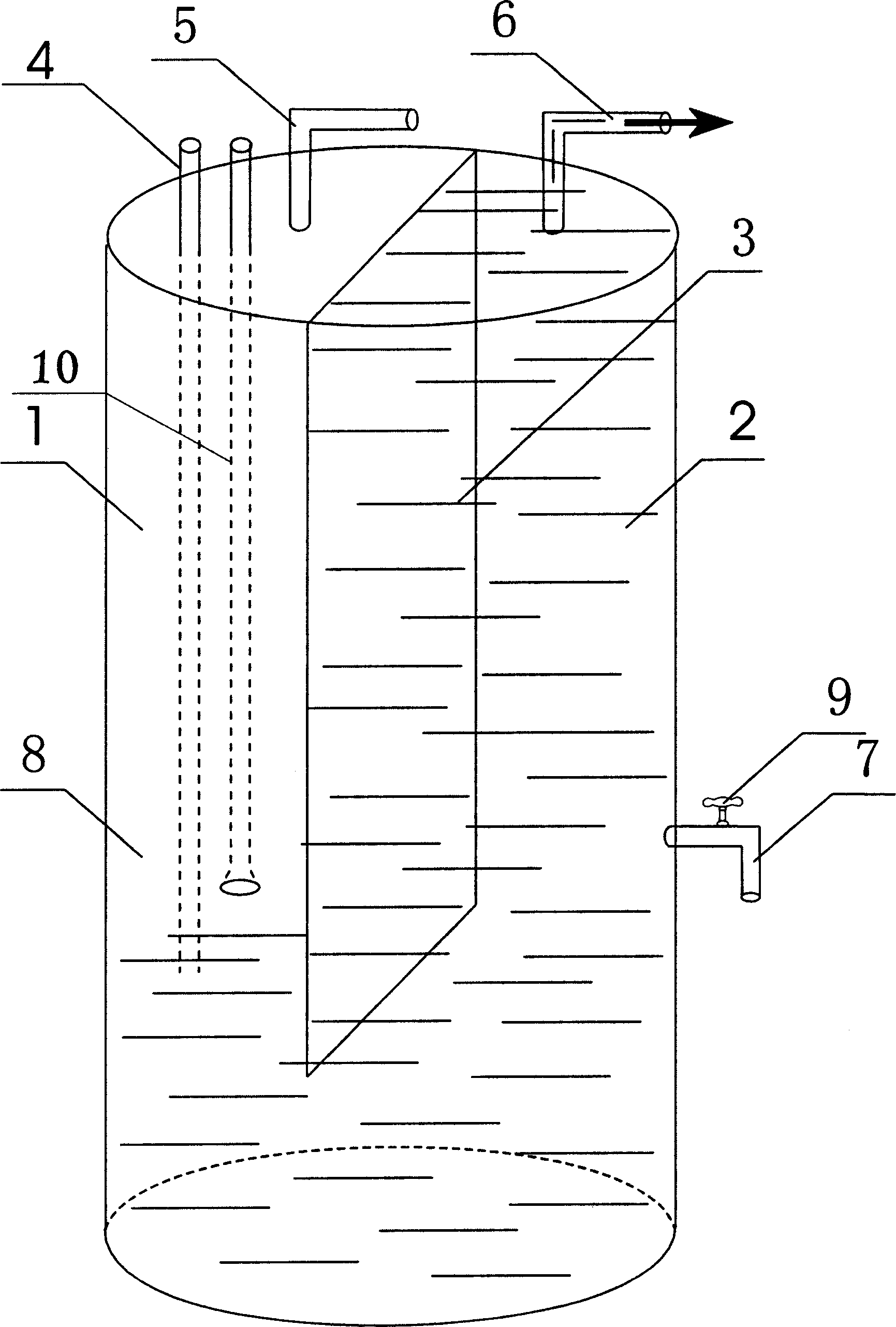

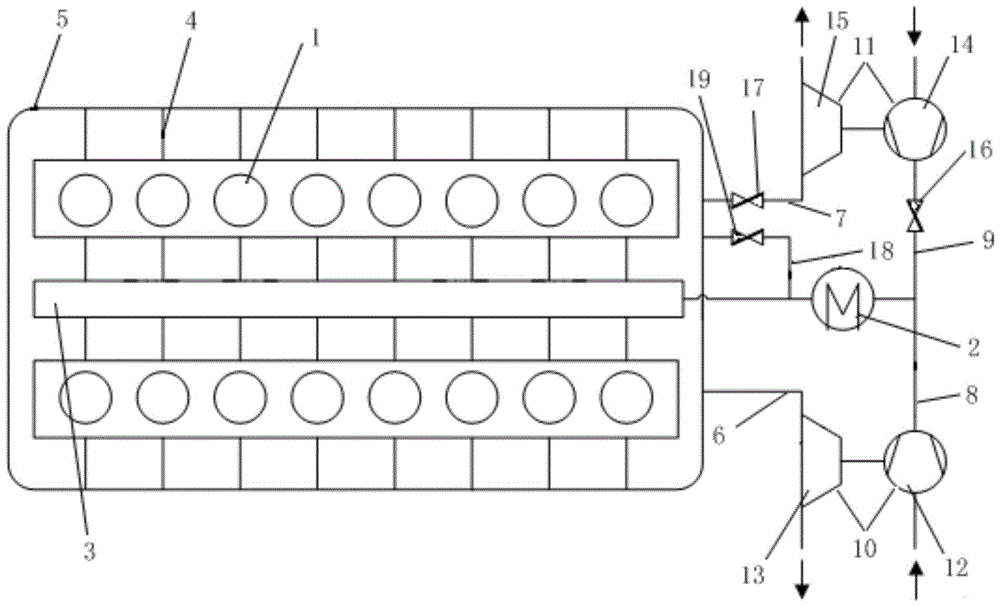

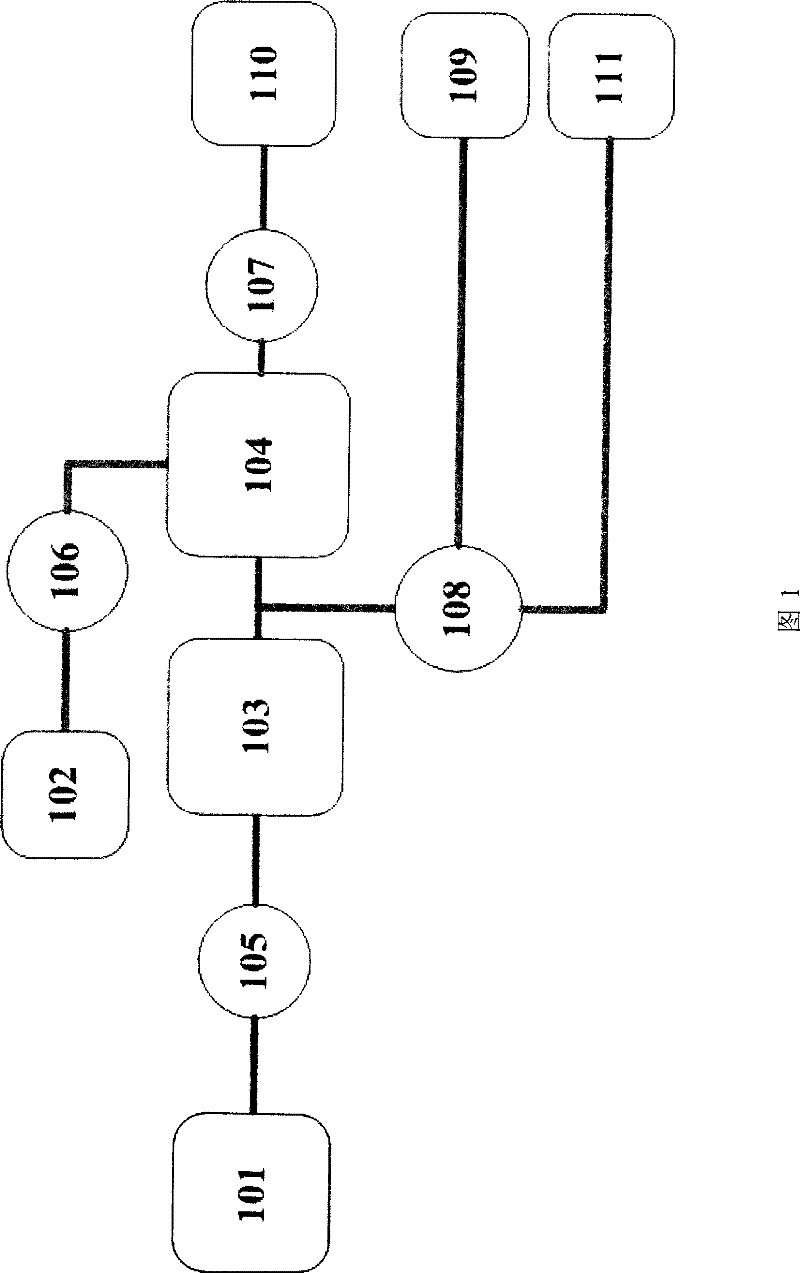

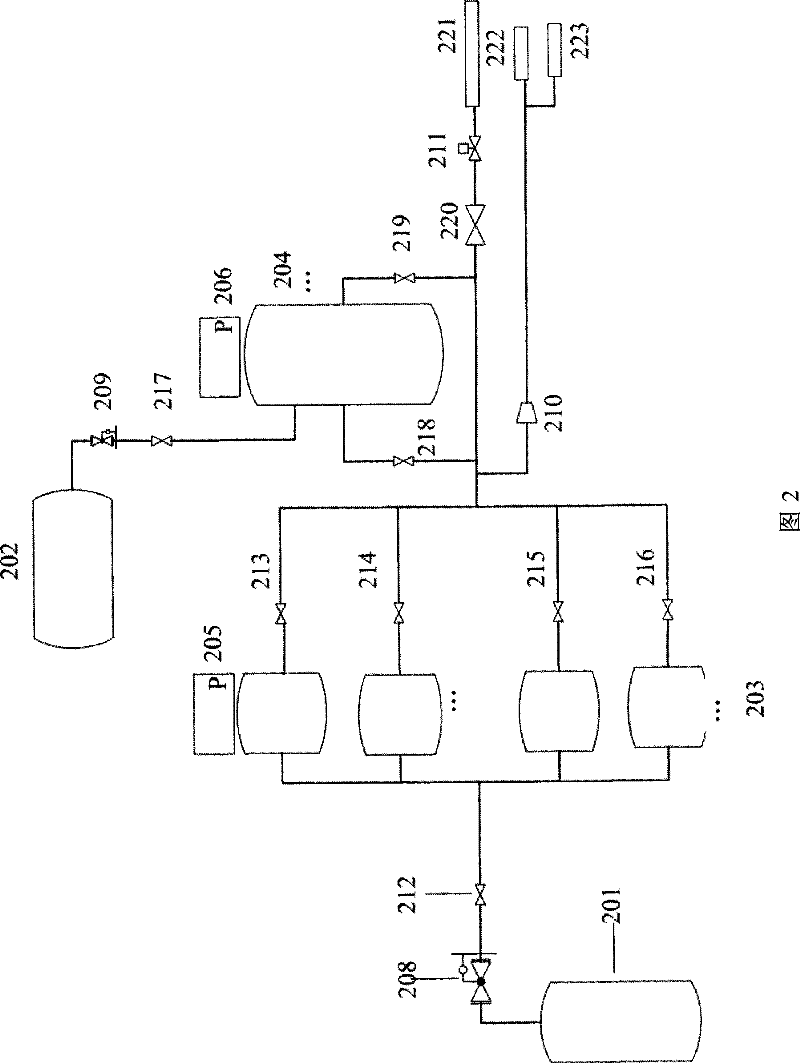

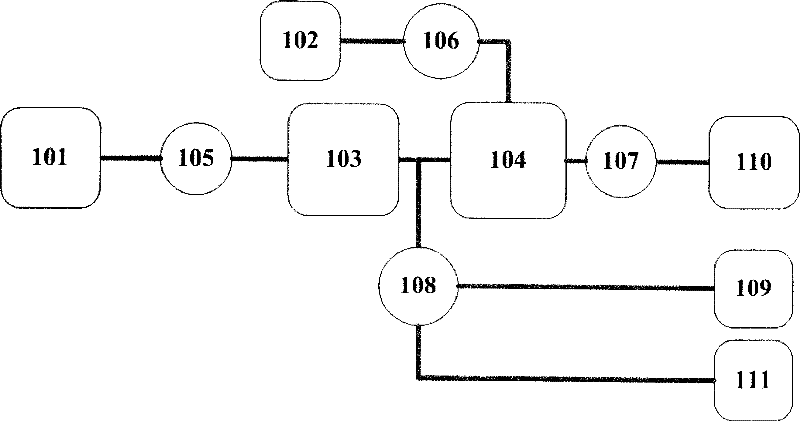

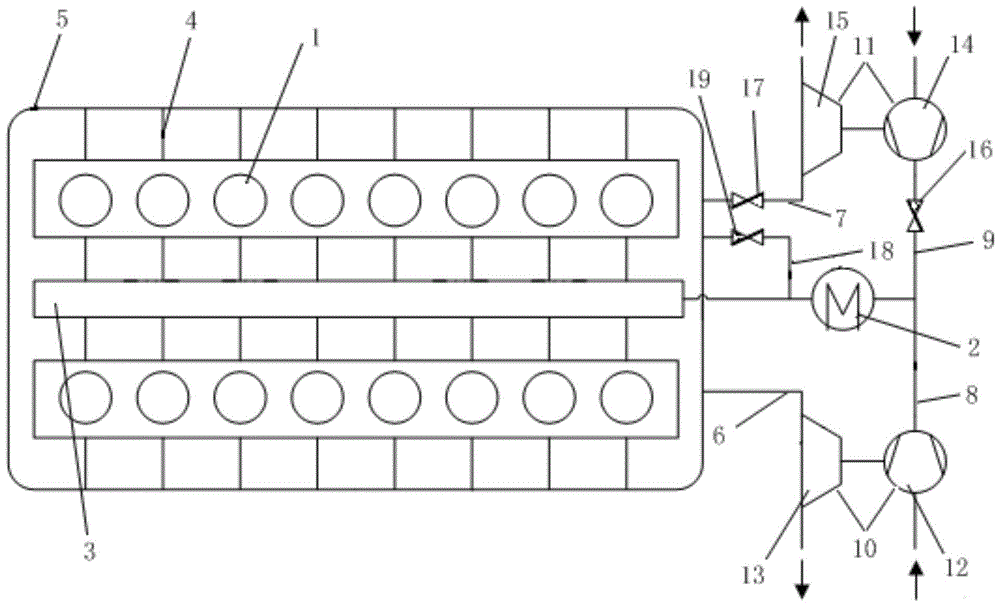

Constant-pressure water-gas compatible cabin power energy storage system

ActiveCN102619668AStable gas pressureGas pressure stabilization controlMachines/enginesEngine componentsGas compressorWater turbine

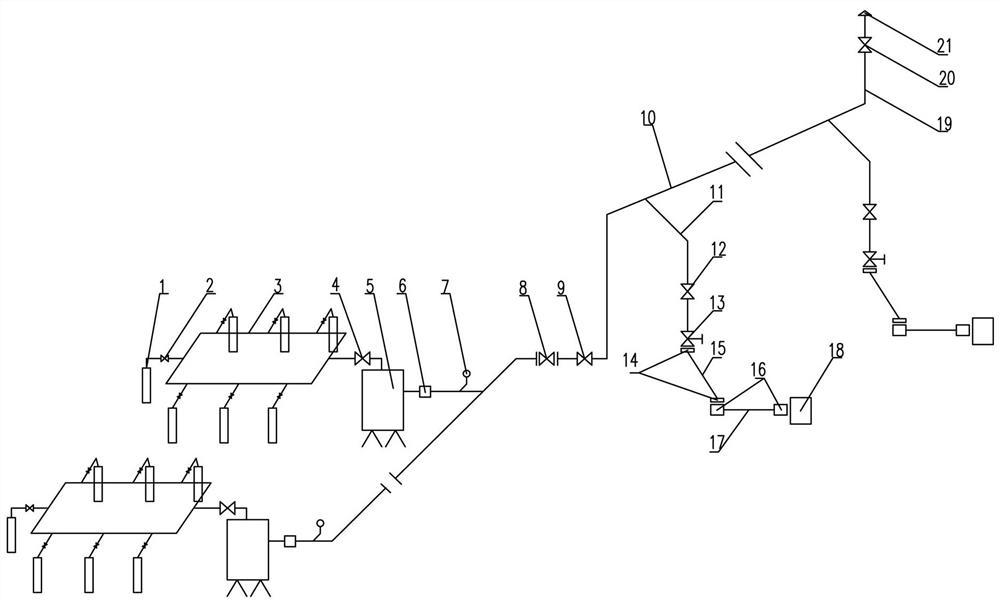

The invention discloses a constant-pressure water-gas compatible cabin power energy storage system. The power energy storage system comprises a water-gas compatible cabin, a gas compressor unit, a water pump unit, a water reservoir and a water turbine, wherein a water draining port of the water turbine is used for providing ingoing water for the water reservoir; the water pump unit is used for pumping water from the water reservoir through a pipeline; an outlet of the gas compression unit is communicated with the water-gas compatible cabin through a valve and a pipeline; an outlet of the water-gas compatible cabin is communicated with the water turbine through a pipeline and a valve; and the water turbine drags a generator to generate power and output power energy. The power energy storage system is characterized by further comprising a steam boiler which is connected with the water-gas compatible cabin through a first intelligent valve and a steam conveying pipeline; one path of an outlet of the water pump unit is communicated with the lower part of the water-gas compatible cabin through a third intelligent valve and a pipeline; another path of the outlet of the water pump unit is communicated with the upper part of the water-gas compatible cabin through a second intelligent valve and a spraying pipe; and the three intelligent valves are controlled by a gas pressure stability control device.

Owner:王焕然

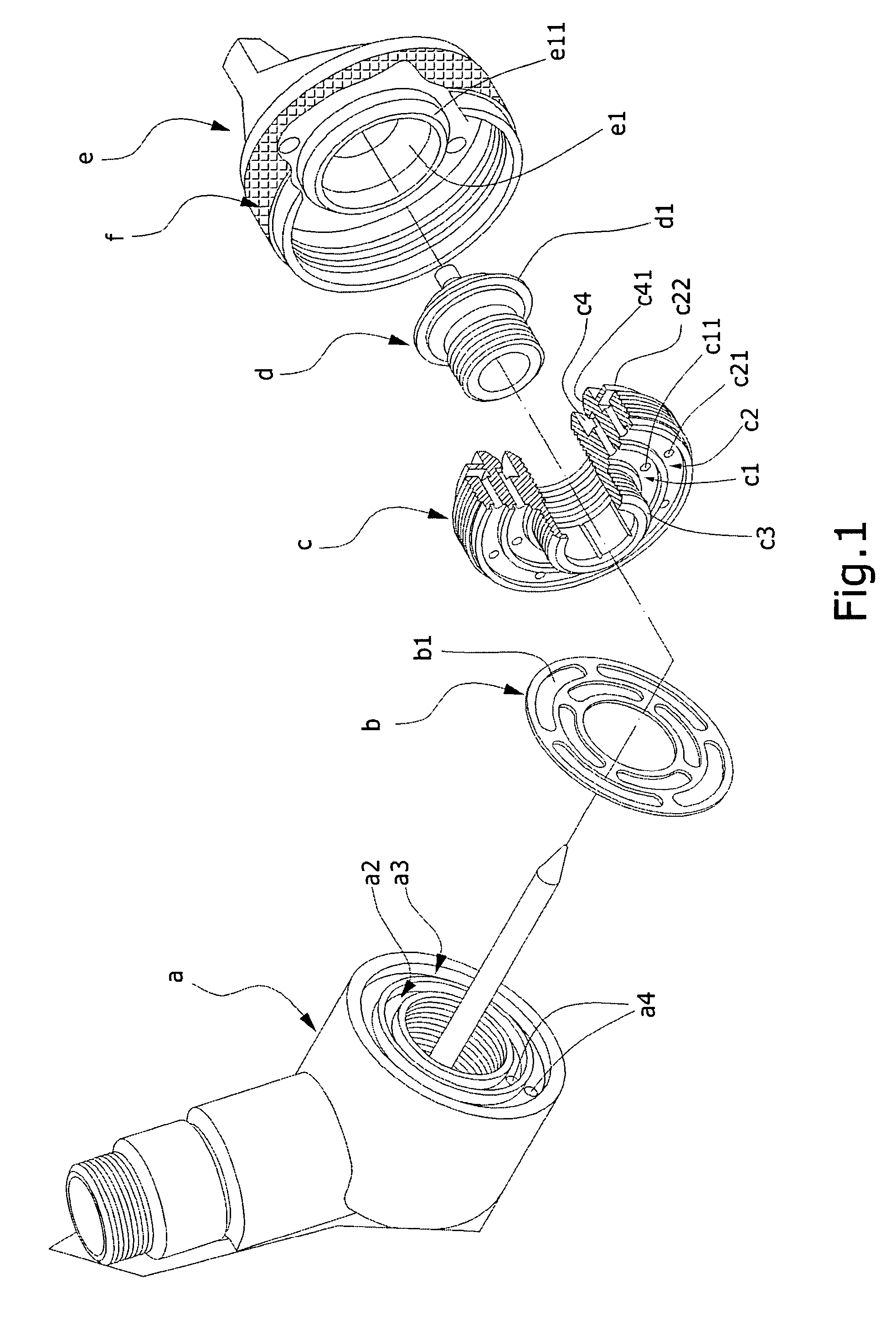

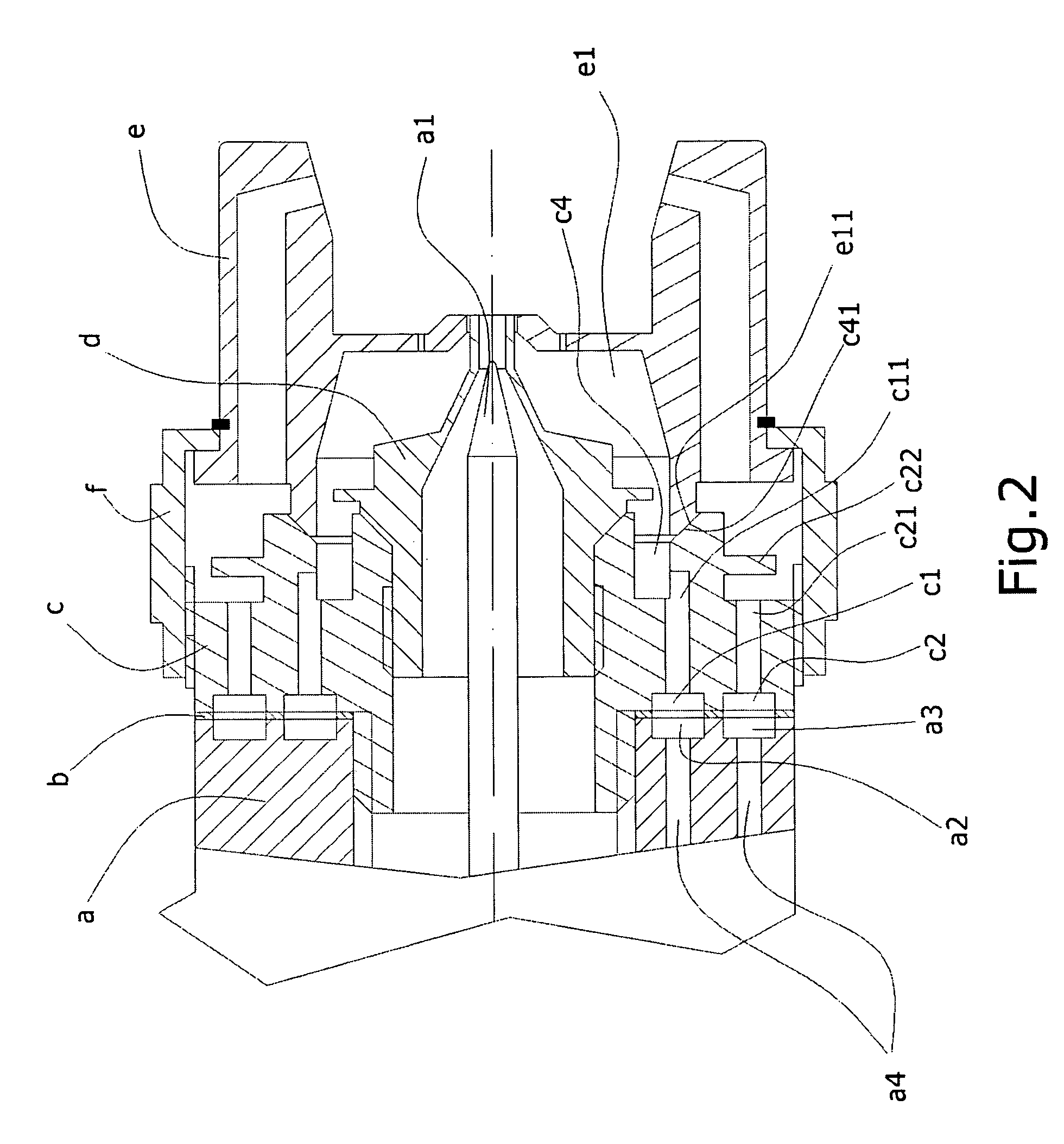

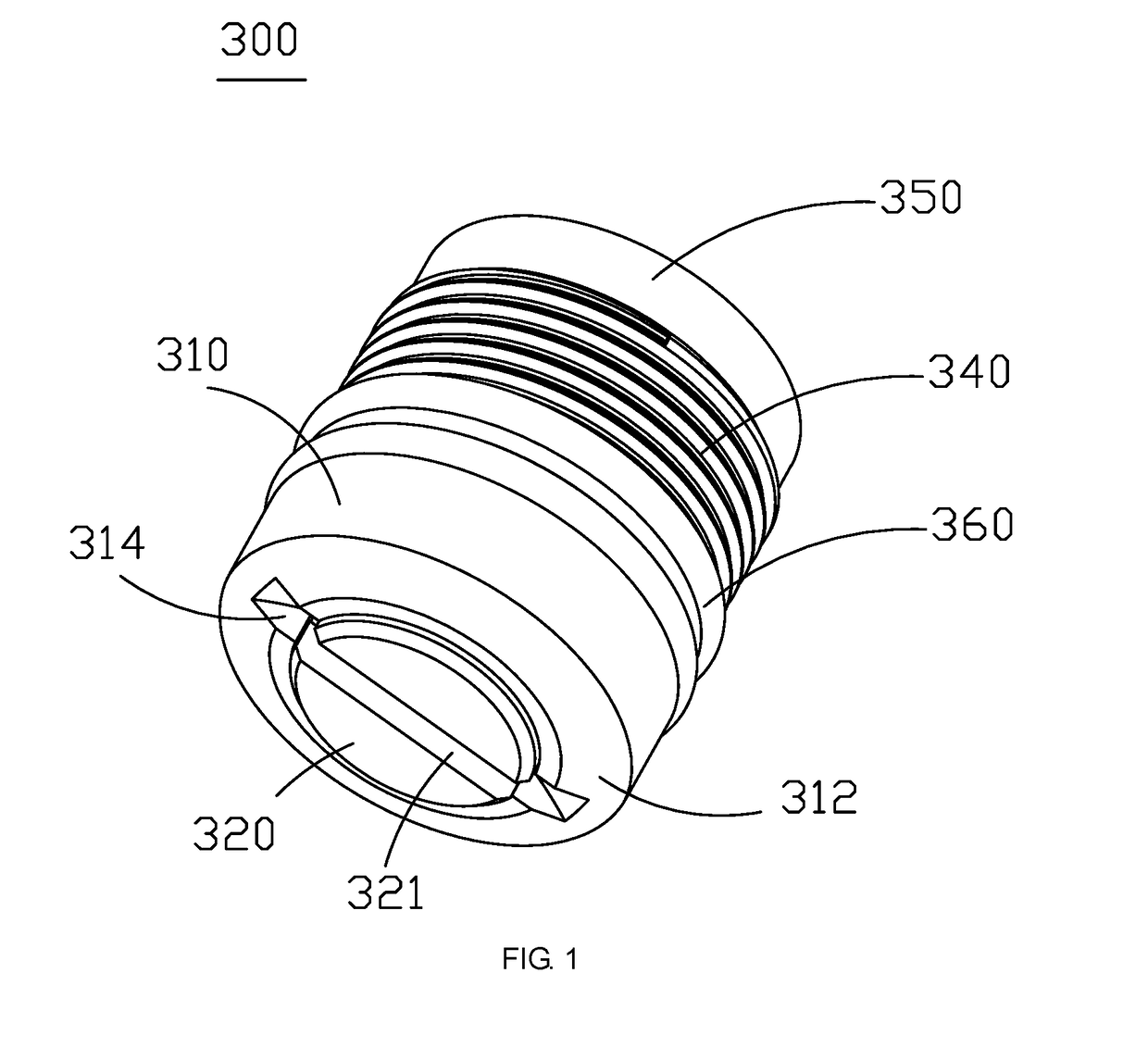

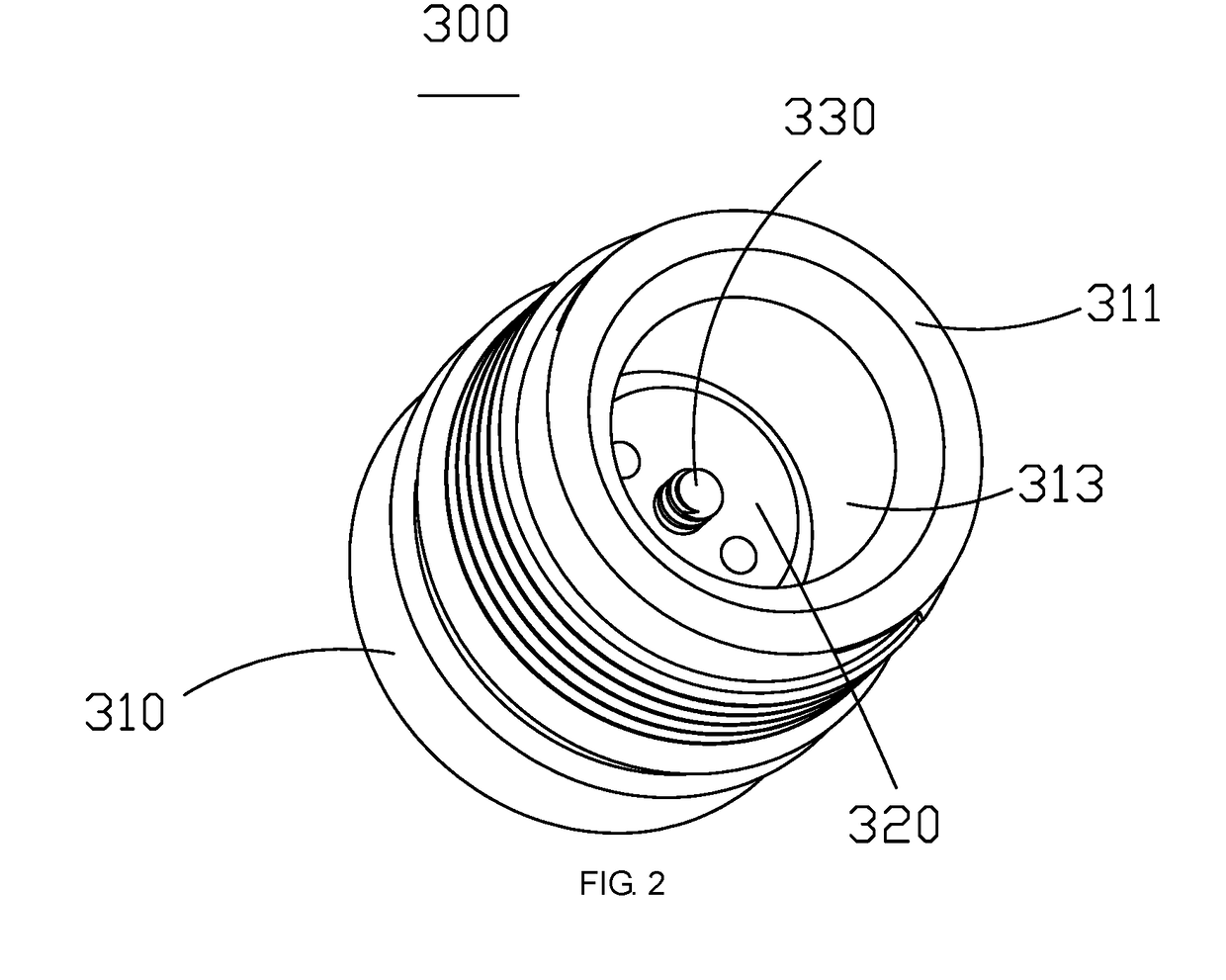

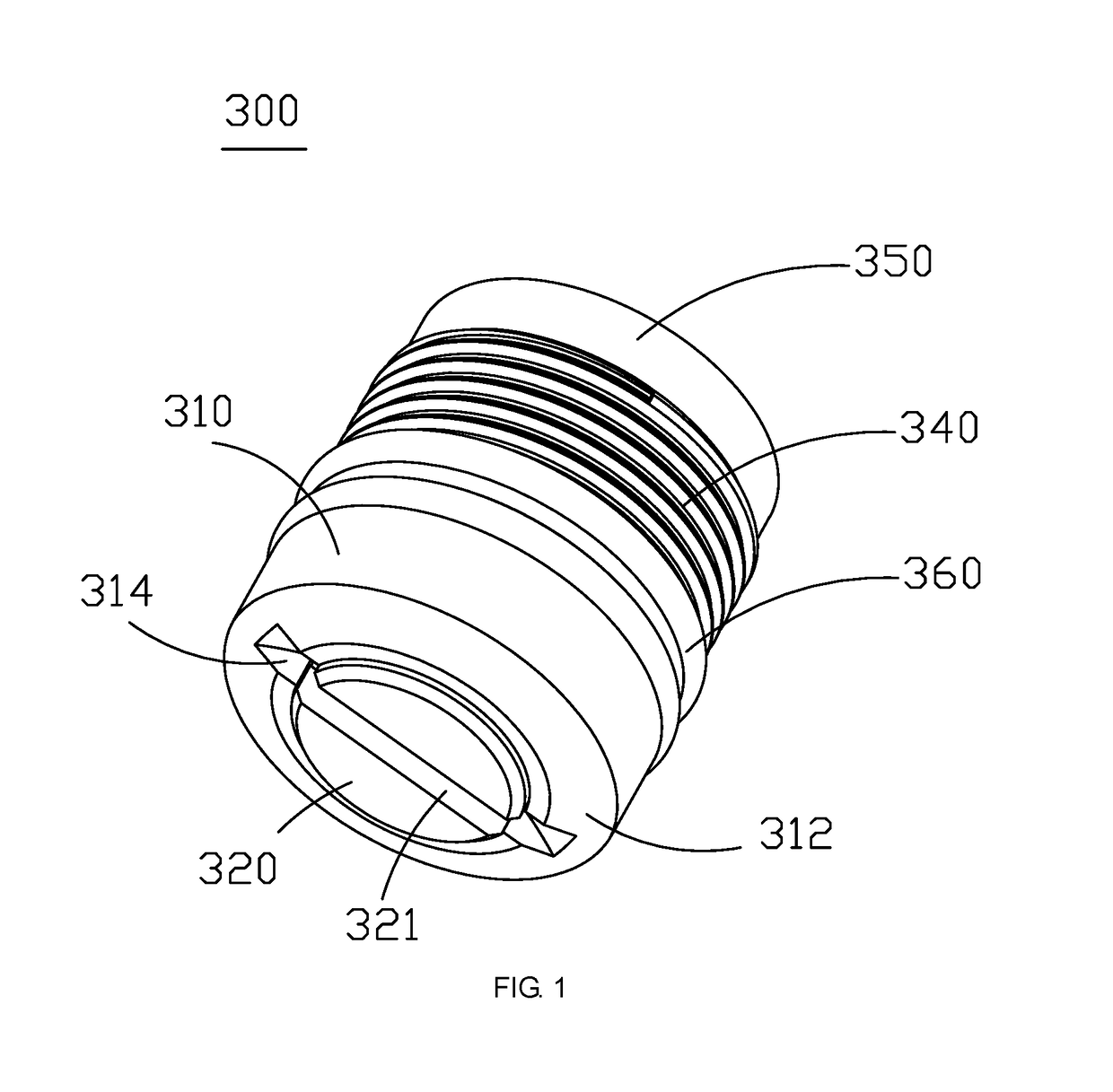

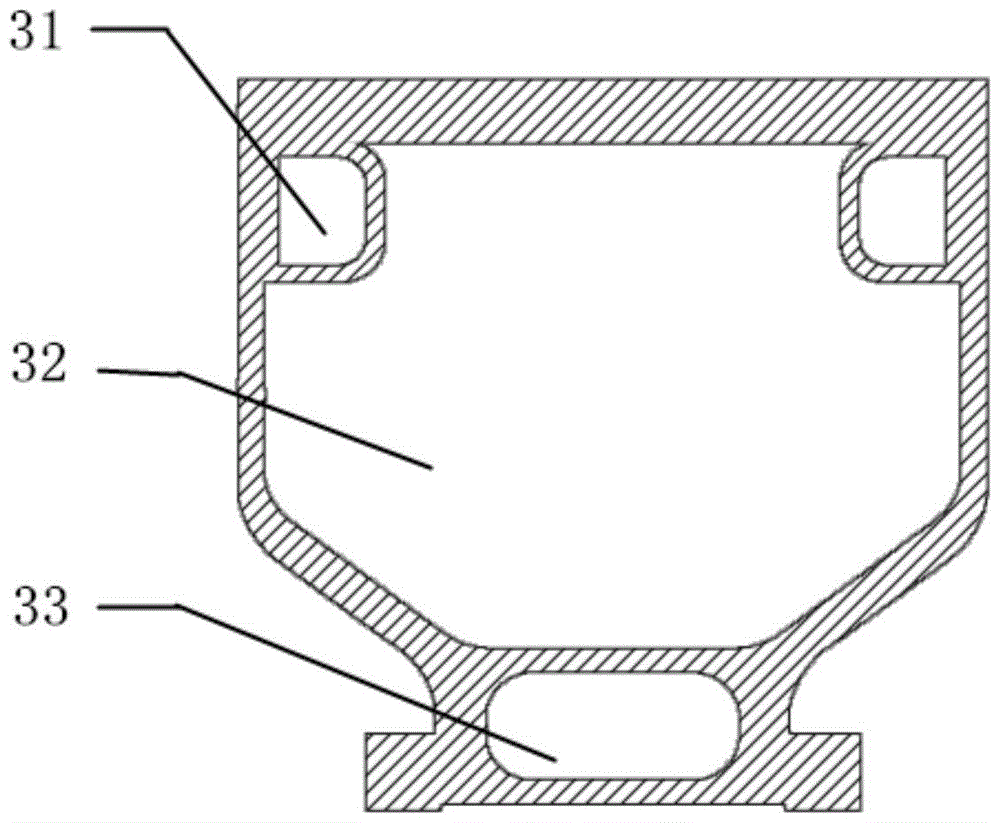

Spray head structure of a spray gun

InactiveUS20070262169A1Stable gas pressureSimple structureSpray nozzlesLiquid spraying apparatusEngineeringHead parts

A spray head structure of a spray gun includes a shunt ring, and two end surfaces of which are extended outward with positioning pillars corresponding to position holes of a fixing seat and the spray gun, respectively. An end surface of the shunt ring, facing to the spray gun, is provided with a shunt sink and an outer gas hole, and the fixing seat is provided with a connection hole and a cover ring. Gas inside the spray gun can be shunted to an interior of spray head and pressure of the gas can be stabilized, by locking a nozzle with the shunt ring and the fixing seat.

Owner:CHIA CHUNG PRECISION INDAL

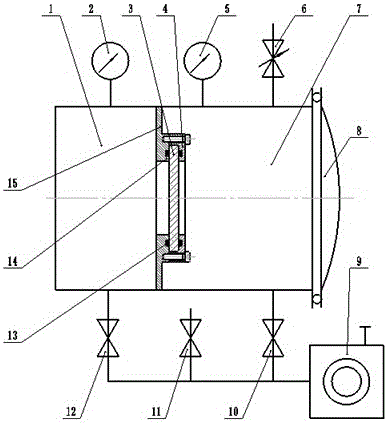

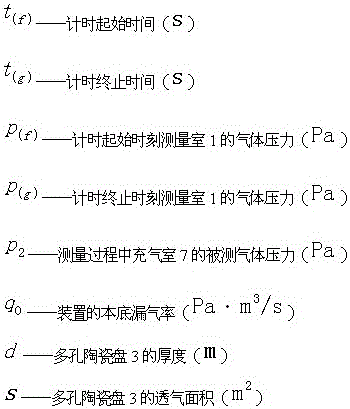

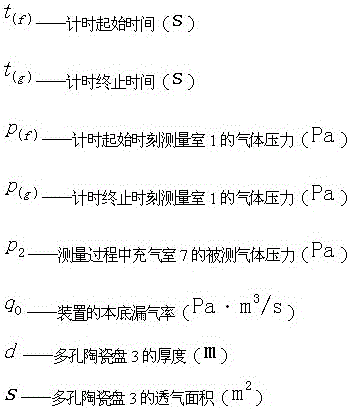

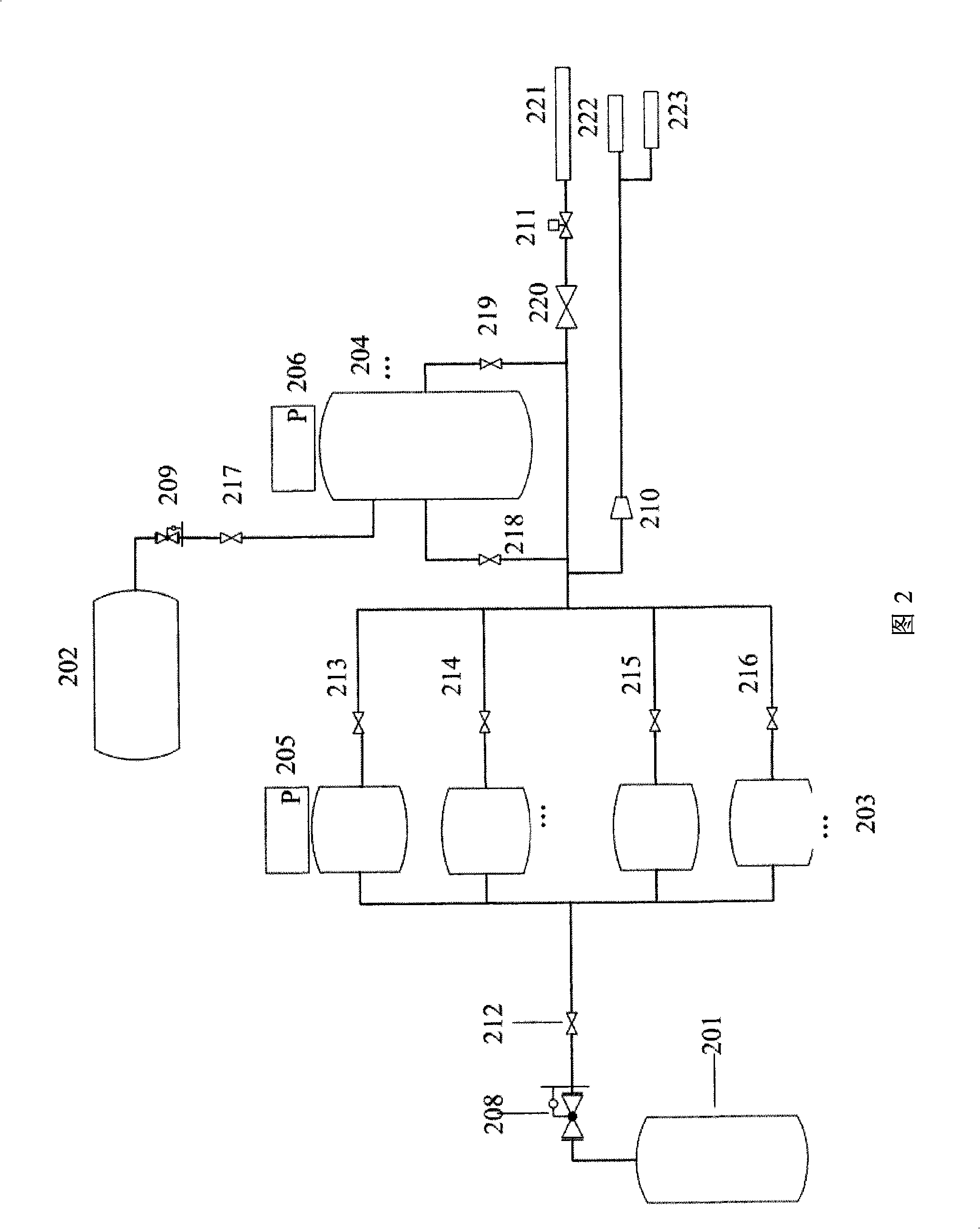

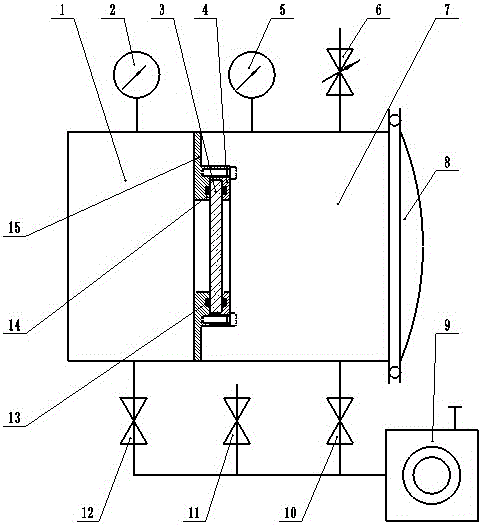

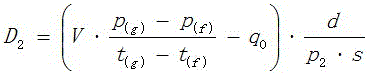

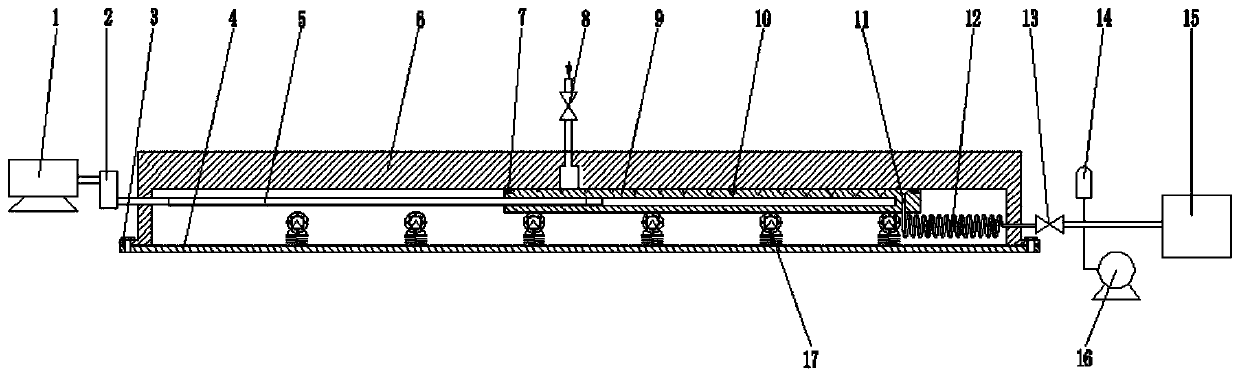

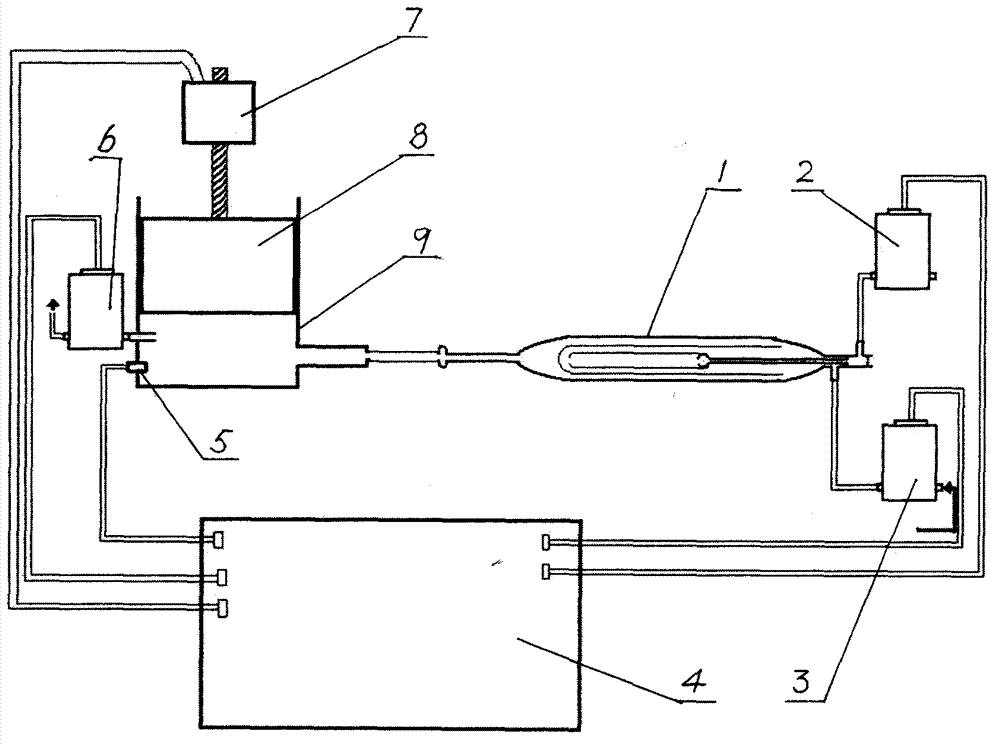

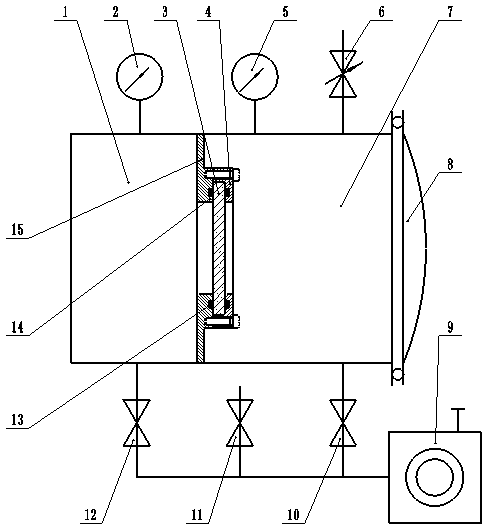

Apparatus and method for measuring gas mass-transfer diffusivity of film material

ActiveCN106092827AIncrease transfer rateStable gas pressureDiffusion analysisPressure differenceVacuum pump

An apparatus and a method for measuring gas mass-transfer diffusivity of film material relate to an apparatus and a method for measurement of a film material. The apparatus comprises two connected vacuum chambers, that is, a measurement chamber and a plenum chamber of which the background leak rate has been determined. The measurement chamber and the plenum chamber are connected through an air exhaust channel with a sealing flange, the sealing flange faces to the side of the plenum chamber, and flange covers and seal rings are utilized for sealing and fixing a disc-shaped blind flange or a test piece; the plenum chamber is provided with an openable plenum chamber door for facilitating mounting or dismounting of the blind flange or the test piece; and the plenum chamber is provided with a plenum-chamber pressure gage, a pneumatic pipeline with a pressure-adjusting control valve and a pumping pipeline with a plenum-chamber valve. The apparatus employs a porous ceramic support material and accelerates gas transportation rate by utilizing a vacuum pump for making a larger pressure difference, and for film materials with low permeability, the apparatus can rapidly obtain stable gas pressure and gas flux data and has accurate measurement result.

Owner:辽宁博仕创业服务中心管理有限公司

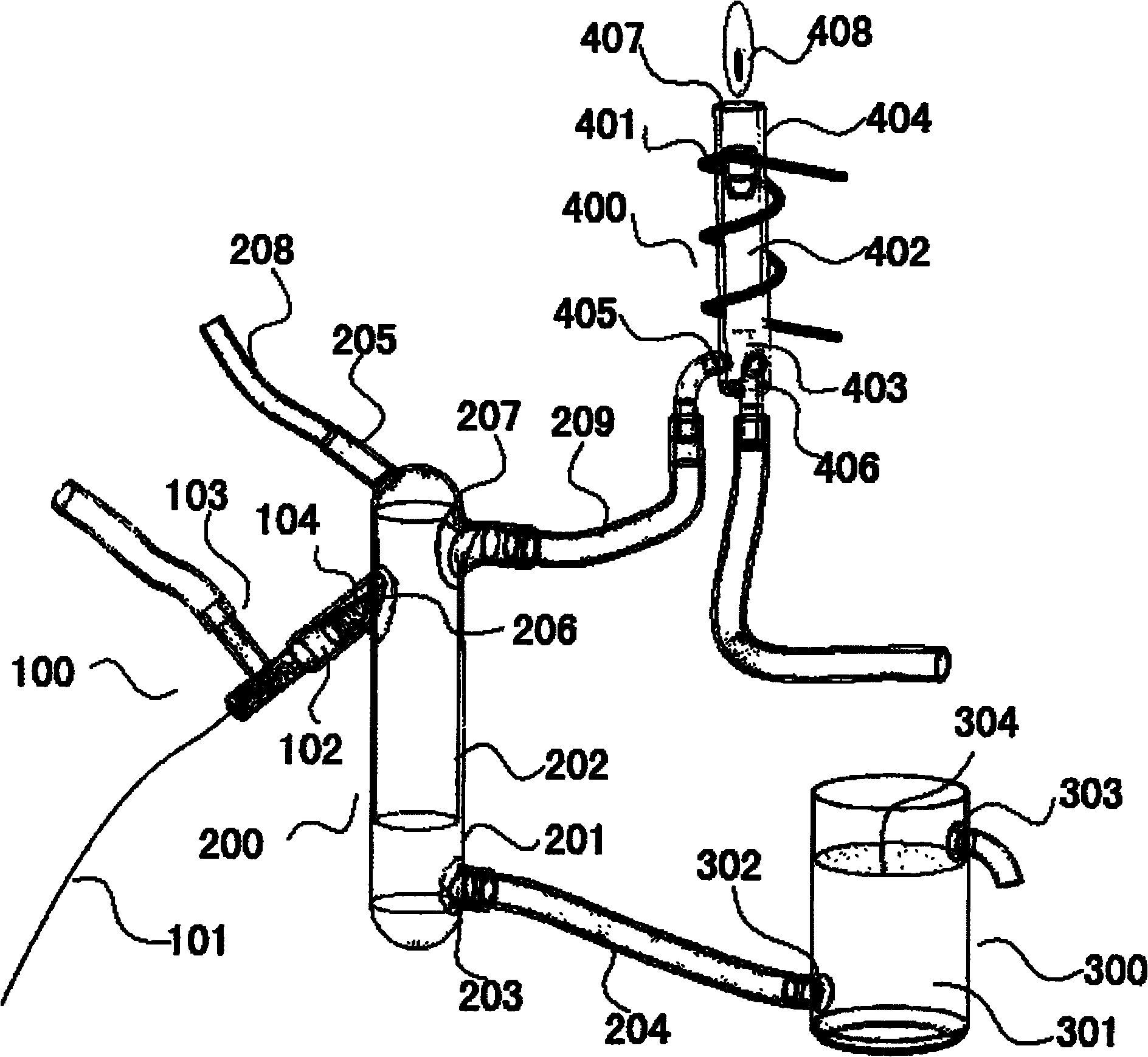

Pipe gas pressure stabilizing regulation system

The invention provides a pipeline gas pressure stabilization regulating system including a pressure monitoring system and a pressure regulating system, the pressure regulating system includes a fuel tank, a first pressure release valve and solenoid switch connected in turn, the solenoid switch connects to a first buffer vessel set, the other end of the first buffer vessel set connects to a regulating valve set by a second buffer vessel set, then connected to a combustor on the one hand; on the other hand the other end of the first buffer vessel set separately connects a secure boot flame and an igniter by a general pressure reducer; a gas pressure sensor in the pressure monitoring system is arranged on the top of the first buffer vessel set and the second buffer vessel set. The inventive system can reduce gas pressure wave motion for maintaining stabilization of the pipeline gas pressure.

Owner:THE QUARTERMASTER EQUIPMENT RESEARCH INSTITUTE OF THE GENERAL LOGISITIC DEPARTME

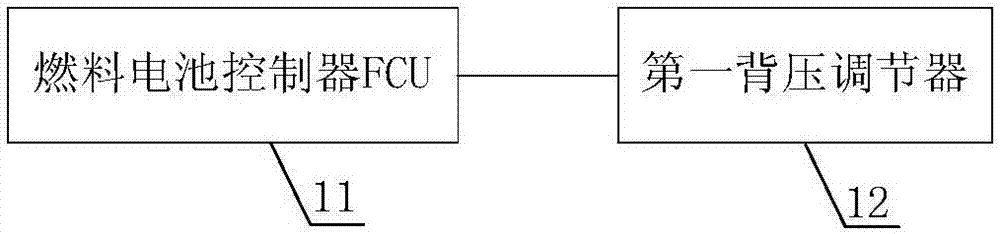

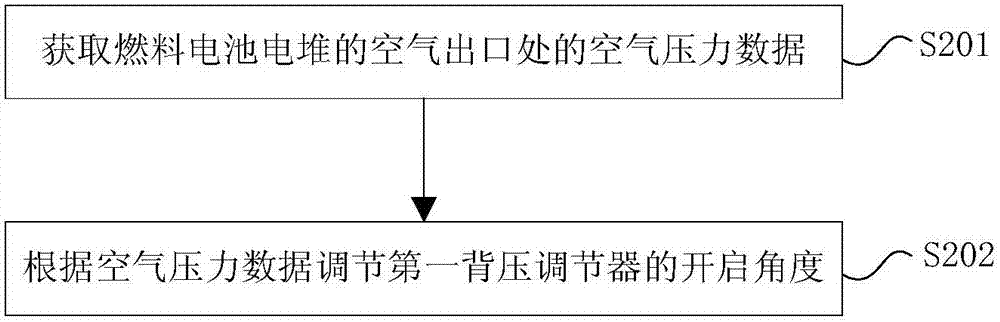

Gas pressure control system and method

The invention discloses a gas pressure control system and method. The gas pressure control system comprises a fuel cell controller FCU and a first back pressure regulator and / or a second back pressure regulator; the first back pressure regulator and / or the second back pressure regulator are / is connected to the FCU; the first back pressure regulator is arranged in an air outlet of a fuel cell stack; the second back pressure regulator is arranged in a hydrogen outlet of the fuel cell stack; the FCU is used for obtaining air pressure data of the air outlet of the fuel cell stack and / or the hydrogen pressure data of the hydrogen outlet of the fuel cell stack and regulating an opening angle of the first back pressure regulator according to the air pressure data and / or regulating an opening angle of the second back pressure regulator according to the hydrogen pressure data. The system and the method solve the problems that the low gas pressure in a flow channel of a fuel cell can affect the reaction efficiency of the fuel cell, the high gas pressure leads to difficulty in pile stealing, and the increase of differential pressure of gas at two sides is easy to cause a damage to a diaphragm in the existing technology.

Owner:上海厚瓴能源科技有限公司

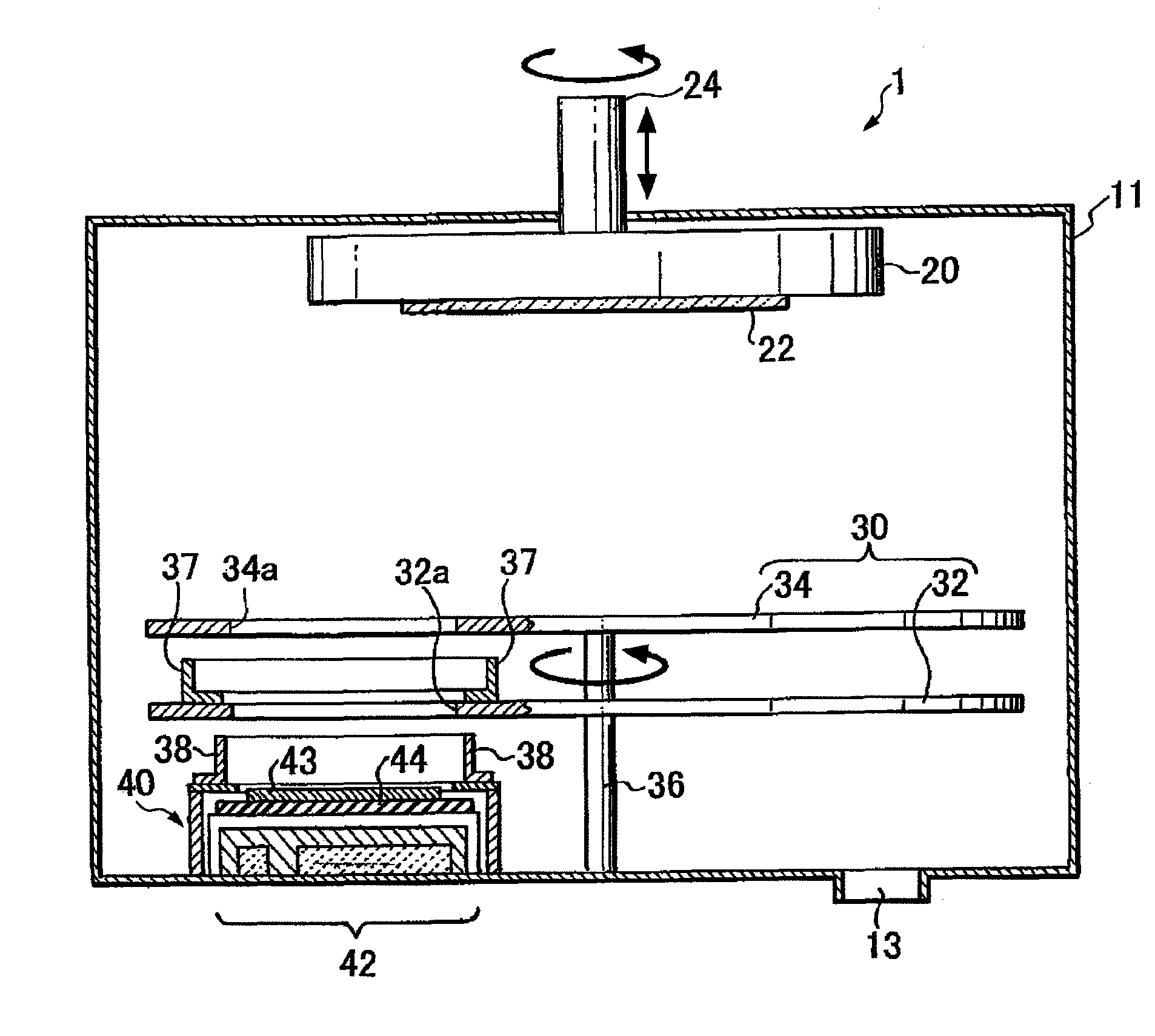

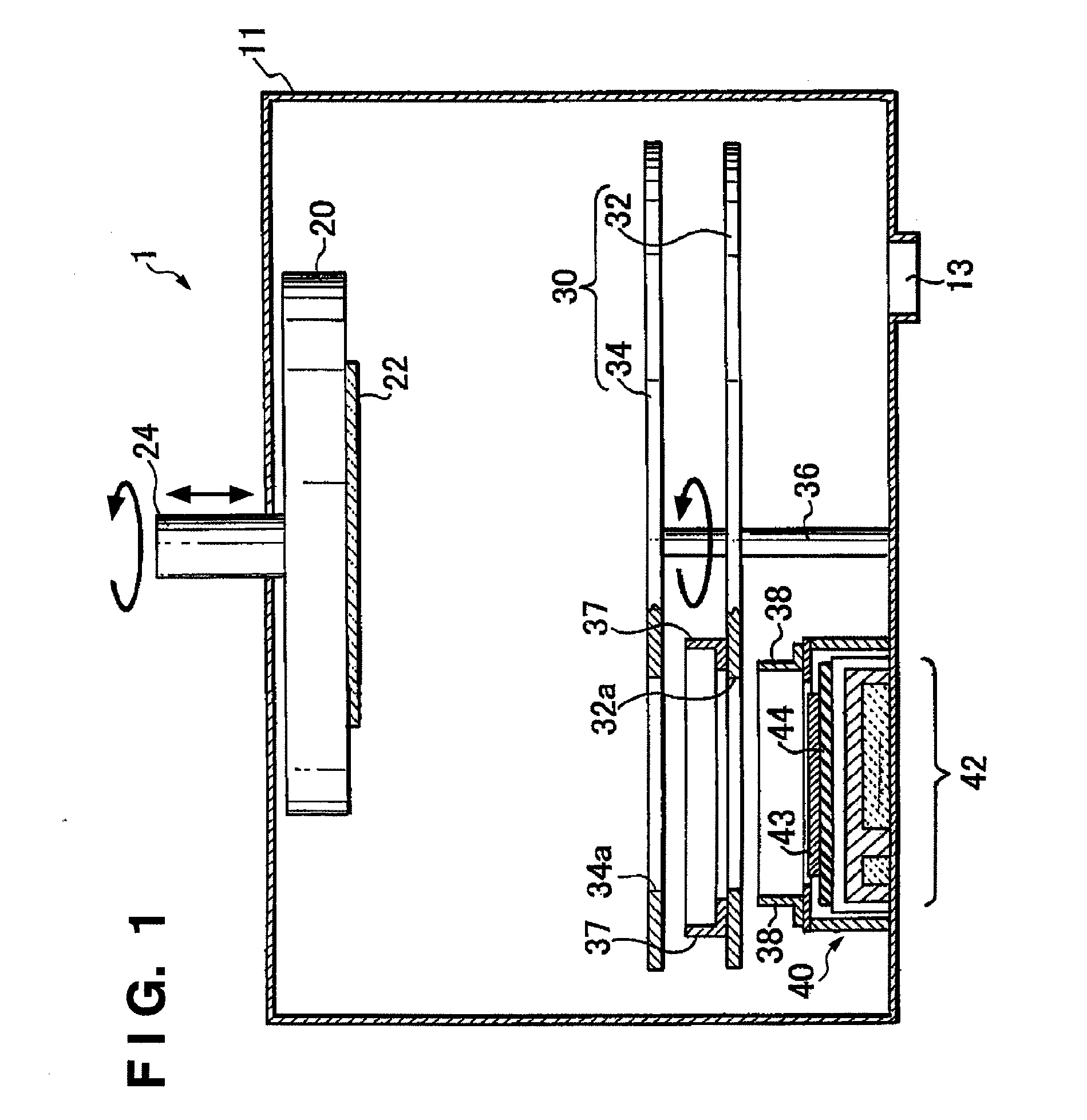

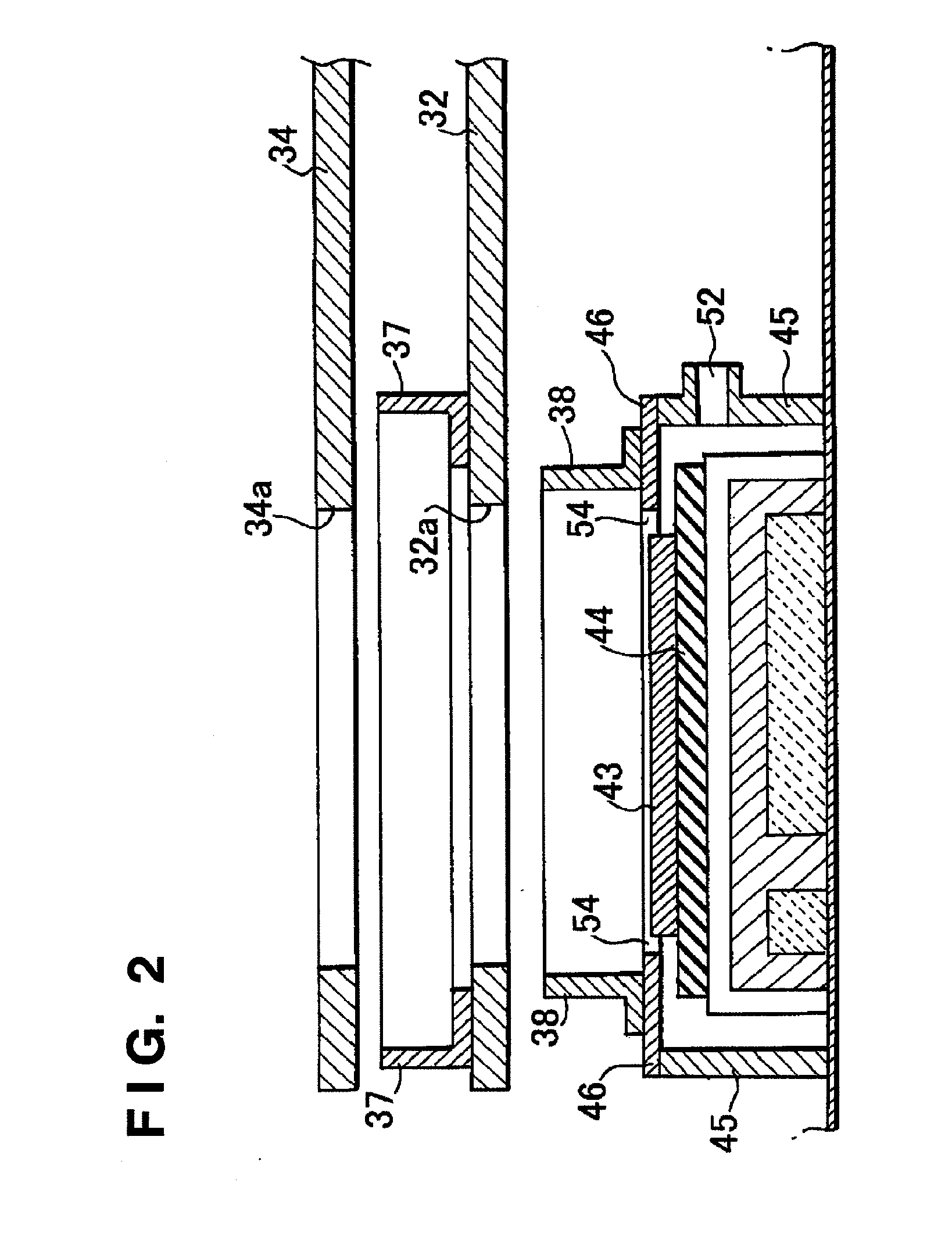

Sputtering apparatus, double rotary shutter unit, and sputtering method

InactiveUS20100206715A1Reliable preventionAvoid cross contaminationCellsElectric discharge tubesSputteringEngineering

Two shutter plates form a double rotary shutter mechanism. A cylindrical second deposition shield is interposed between the first shutter plate disposed on the side of a target and the second shutter plate so as to surround a first opening formed in the first shutter plate. A cylindrical first deposition shield is interposed between a sputtering cathode and the first shutter plate so as to surround the front surface region of the target. This makes it possible to prevent a sputtering substance from passing through the gaps between the first shutter plate and the second shutter plate and between the first shutter plate and the sputtering cathode, and to, in turn, prevent generation of any cross-contamination.

Owner:CANON ANELVA CORP

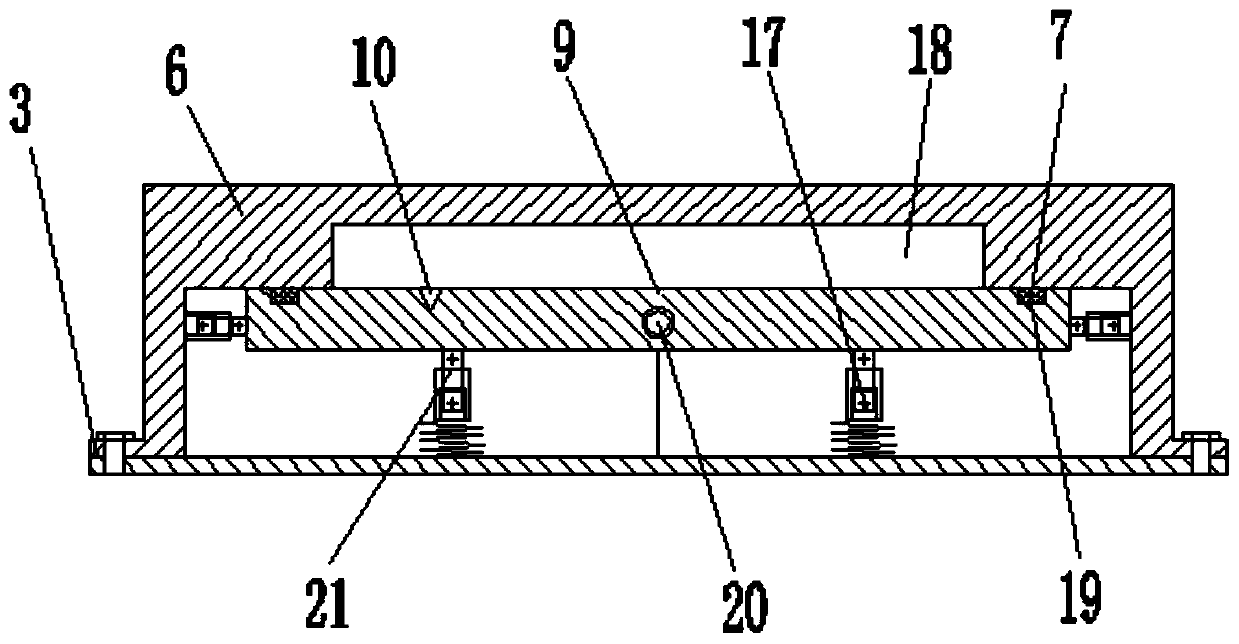

Apparatus and method for determining gas diffusion coefficient of low-intensity low-permeability coating material

ActiveCN106092826AIncrease transfer rateEffective shape measurementDiffusion analysisChamber pressureTest sample

The invention provides an apparatus and a method for determining gas diffusion coefficient of a low-intensity low-permeability coating material, which relates to the coating material coefficient determination apparatus and the method thereof. The apparatus comprises two paralleled vacuum chambers of a measuring chamber and an aeration chamber which are connected through an air exhaust channel with a seal flange, the seal flange faces to one side of the aeration chamber, a disk shaped blank flange or a test sample is fixed in a sealing mode by using a flange gland and a sealing ring; an operable aeration chamber door is arranged in the aeration chamber, which is used for arranging or dismounting the blank flange or the test sample; an aeration chamber pressure gauge, an aeration pipeline having a pressure adjusting control valve and an air exhaust pipeline having an aeration chamber valve are arranged in the aeration chamber; the measuring chamber pressure gauge and the air exhaust pipeline having a measuring chamber valve are arranged in the measuring chamber, and the background leakage rate of the measuring chamber is relatively stationary. The apparatus can use a thin coating material for measurement, for the low-permeability coating material, data for stabilization of gas pressure and gas flux can be rapidly acquired, and the measurement result is accurate.

Owner:辽宁博仕创业服务中心管理有限公司

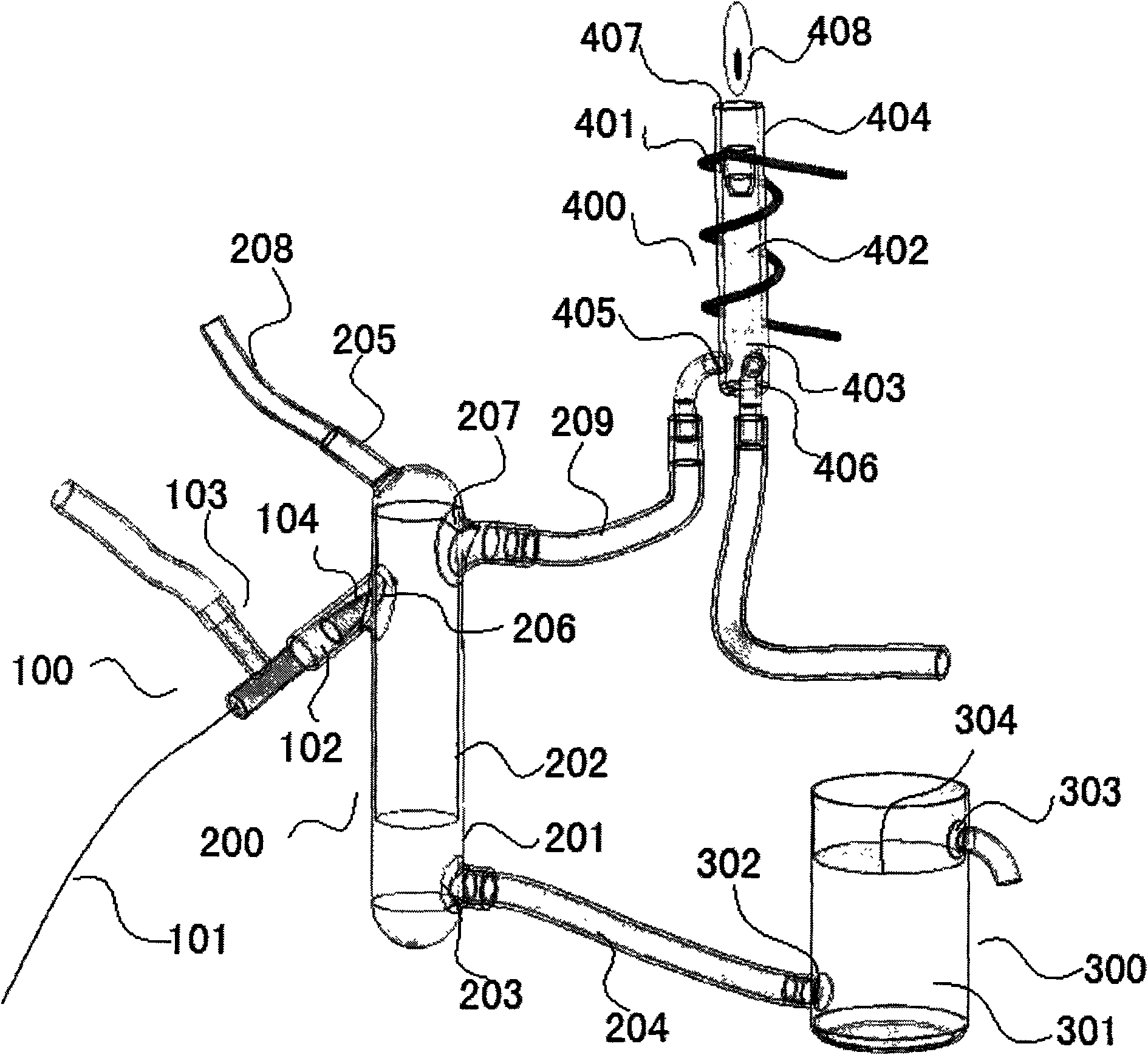

Sensitive and stable atomic fluorescence generating system capable of atomizing continuously

InactiveCN102012369AEasy to collectAvoid interferenceFluorescence/phosphorescenceElectricityHydrogen

The invention discloses a sensitive and stable atomic fluorescence generating system capable of atomizing continuously. The system comprises an electrically heated quartz tube, an argon source, a solution atomizer, a gas-liquid separating and gas mixing device, a water seal, and a hydrogen generator, wherein the solution atomizer is connected with the argon source and the gas-liquid separating and gas mixing device which is respectively communicated with the hydrogen generator, the electrically heated quartz tube and the water seal. The sensitive and stable atomic fluorescence generating system capable of atomizing continuously has the advantages of stable flame, high atomic fluorescence sensitivity and high sample atomizing efficiency, and has the characteristic of continuous sample introduction, so that an analytical instrument can reduce the measurement error through prolonging the measurement time so as to obtain ideal measurement precision and detection limit.

Owner:SHANGHAI SPECTRUM INSTR

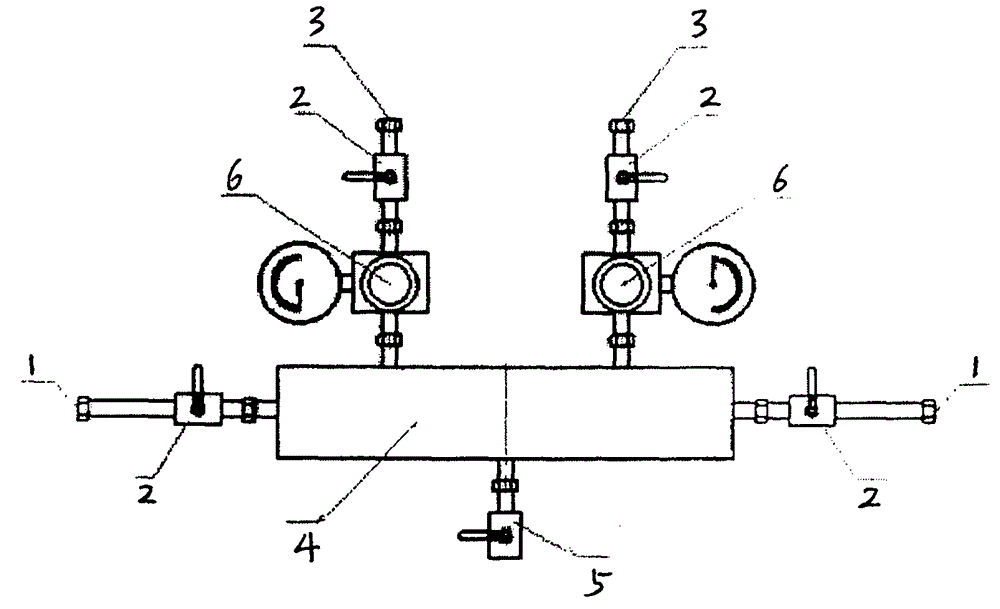

Gas control device

InactiveCN105276378AReduce shockExtended useful lifePipeline systemsPressure vesselsProcess engineeringCorrosion

The invention relates to a gas control device. The gas control device comprises two gas inlet pipes provided with gas inlet valves, and two gas outlet pipes provided with gas outlet valves. The gas control device is characterized in that the gas control device is further provided with a gas storage chamber, and a water drainage valve is arranged below the gas storage chamber. By arranging the gas storage chamber, it is ensured that gas pressure in a pipeline can be kept within the working pressure range, the working pressure standard can be met even when an air curtain spraying device is suddenly started, and no pressure loss phenomenon can be generated. Moisture condensed in the pipeline can be removed through the gas storage chamber, and corrosion to the whole pipeline caused when moisture can not be removed and is accumulated can not happen. Foreign matter which can possibly be generated in a gas way is eliminated, and the danger that air curtain spraying holes are blocked by the foreign matter is reduced. Impact of high-pressure gas on the pipeline is reduced, the service life of the pipeline is prolonged, the working pressure of high-pressure gas is stabilized, and normal work of an air curtain spraying system is ensured.

Owner:黑龙江省华升救援装备有限公司

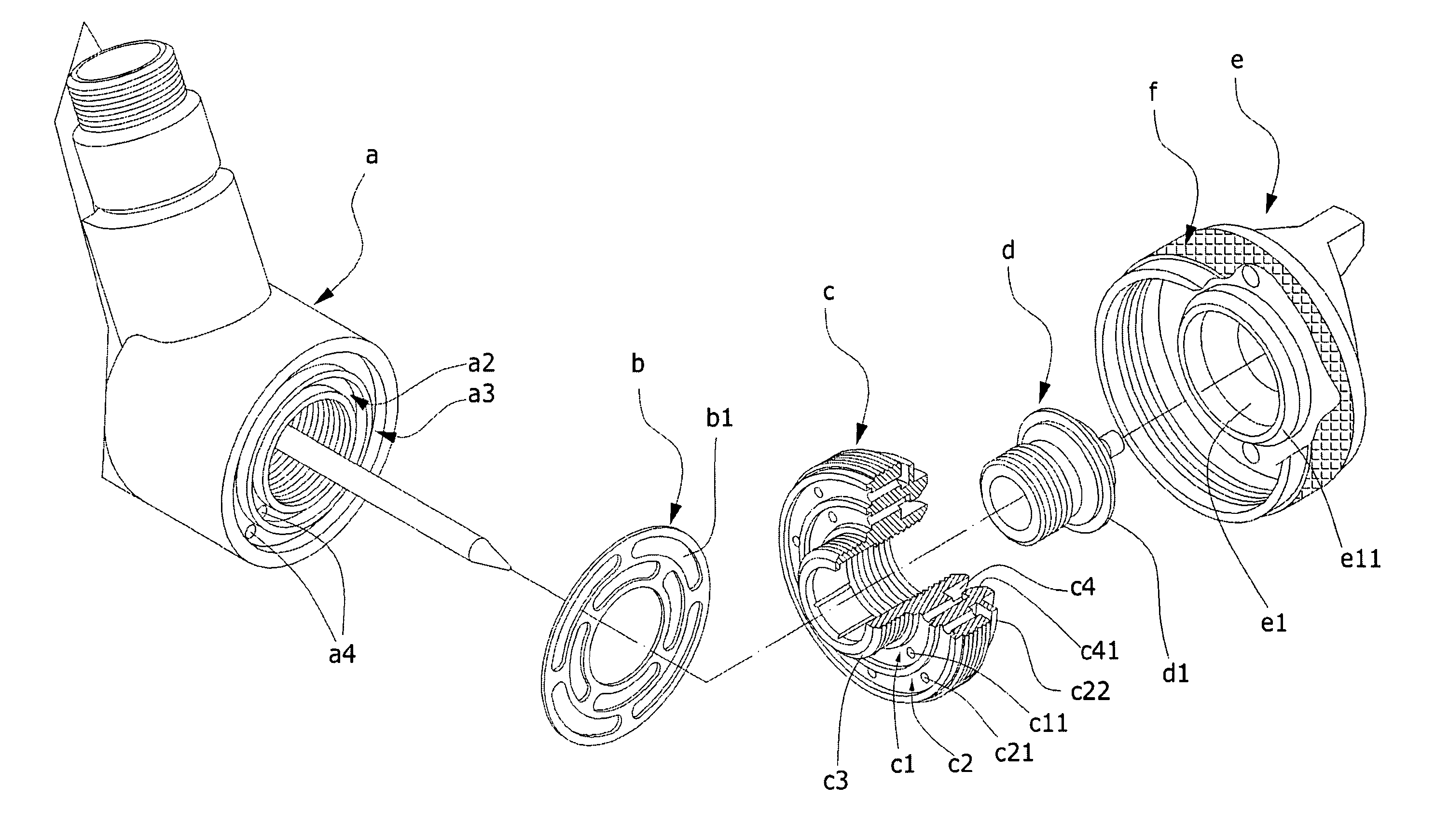

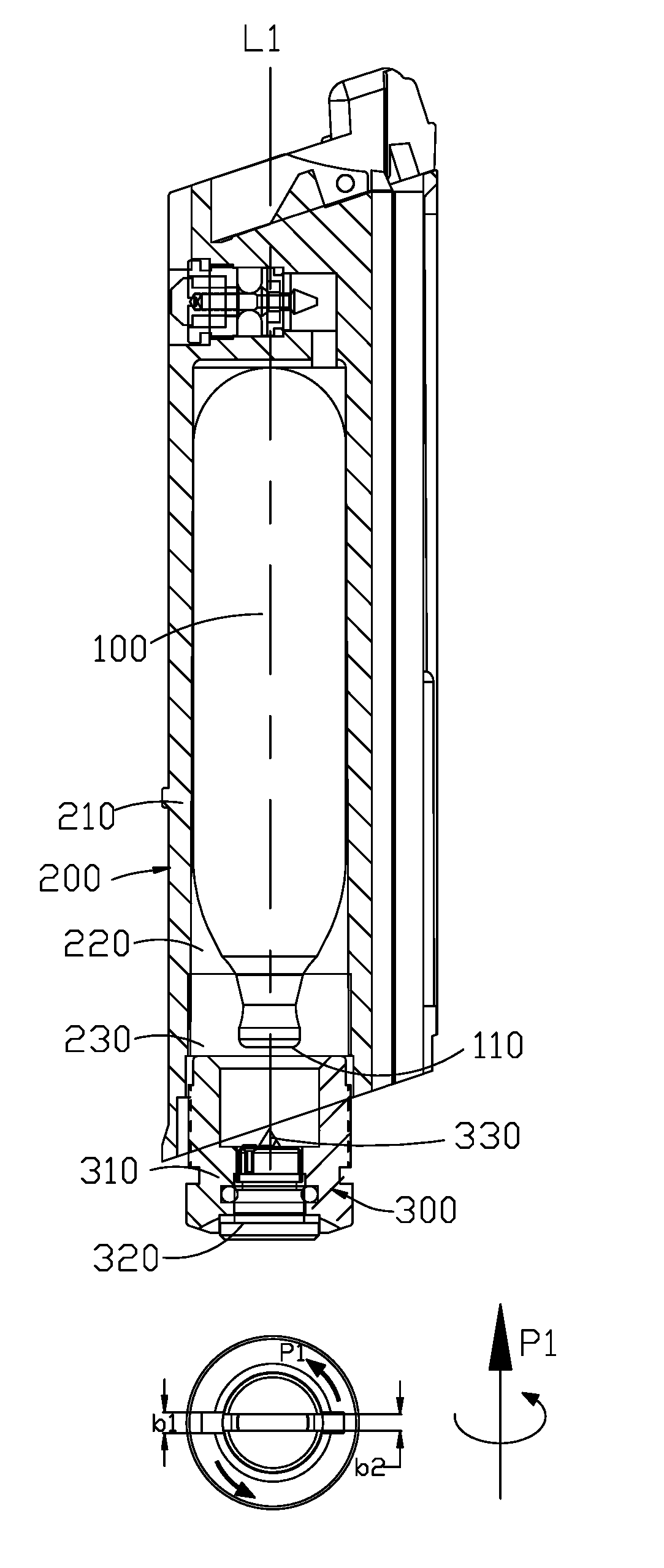

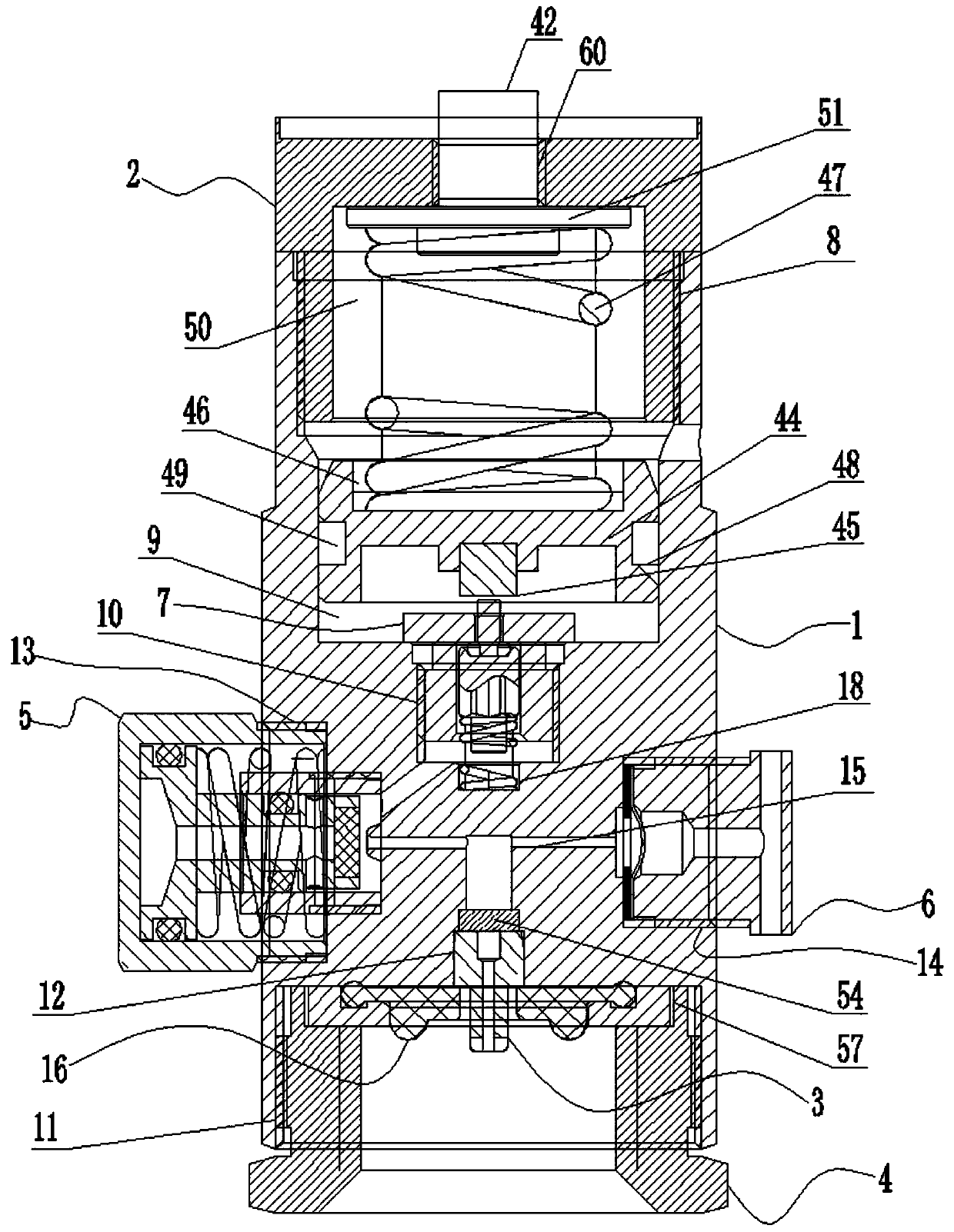

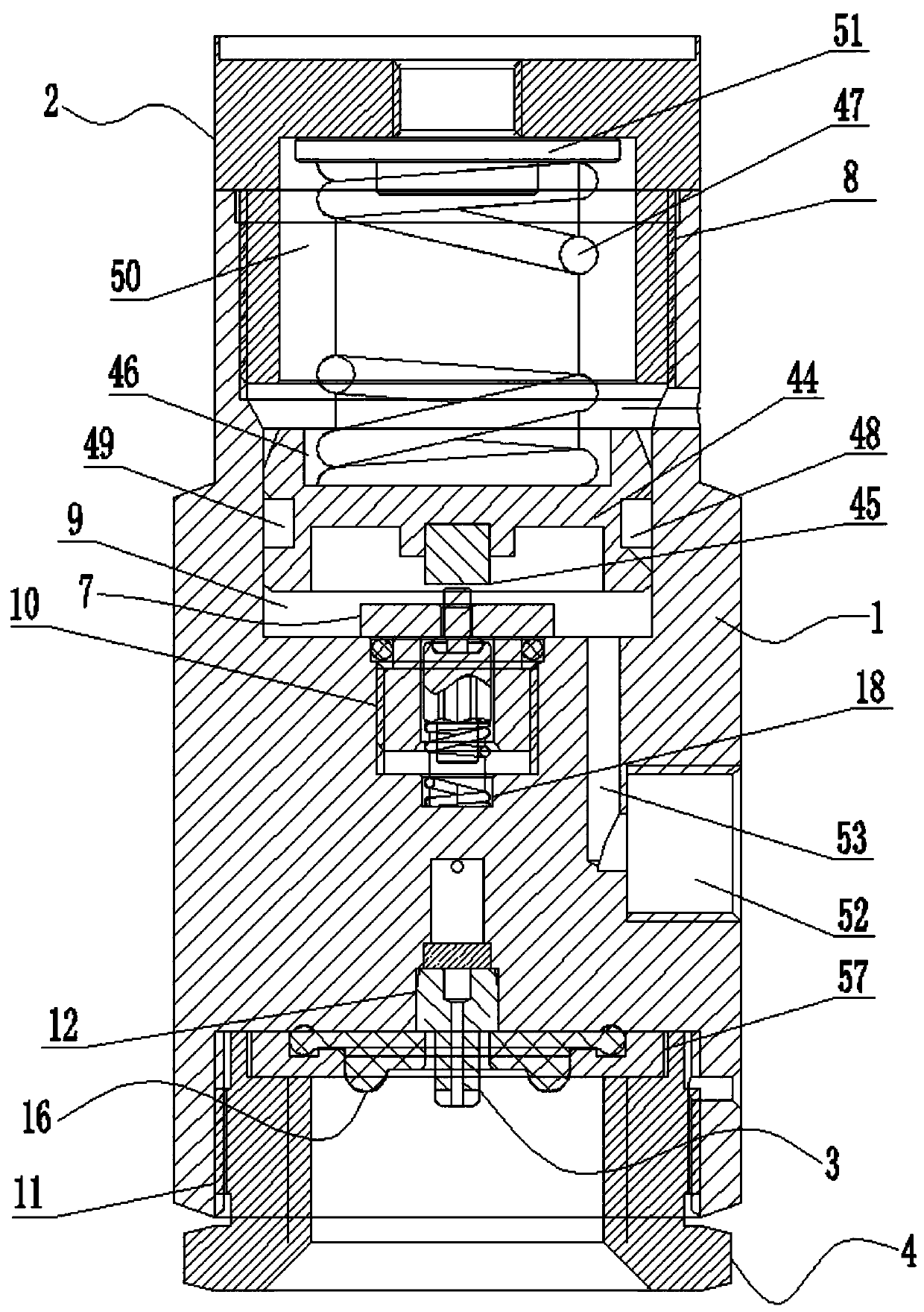

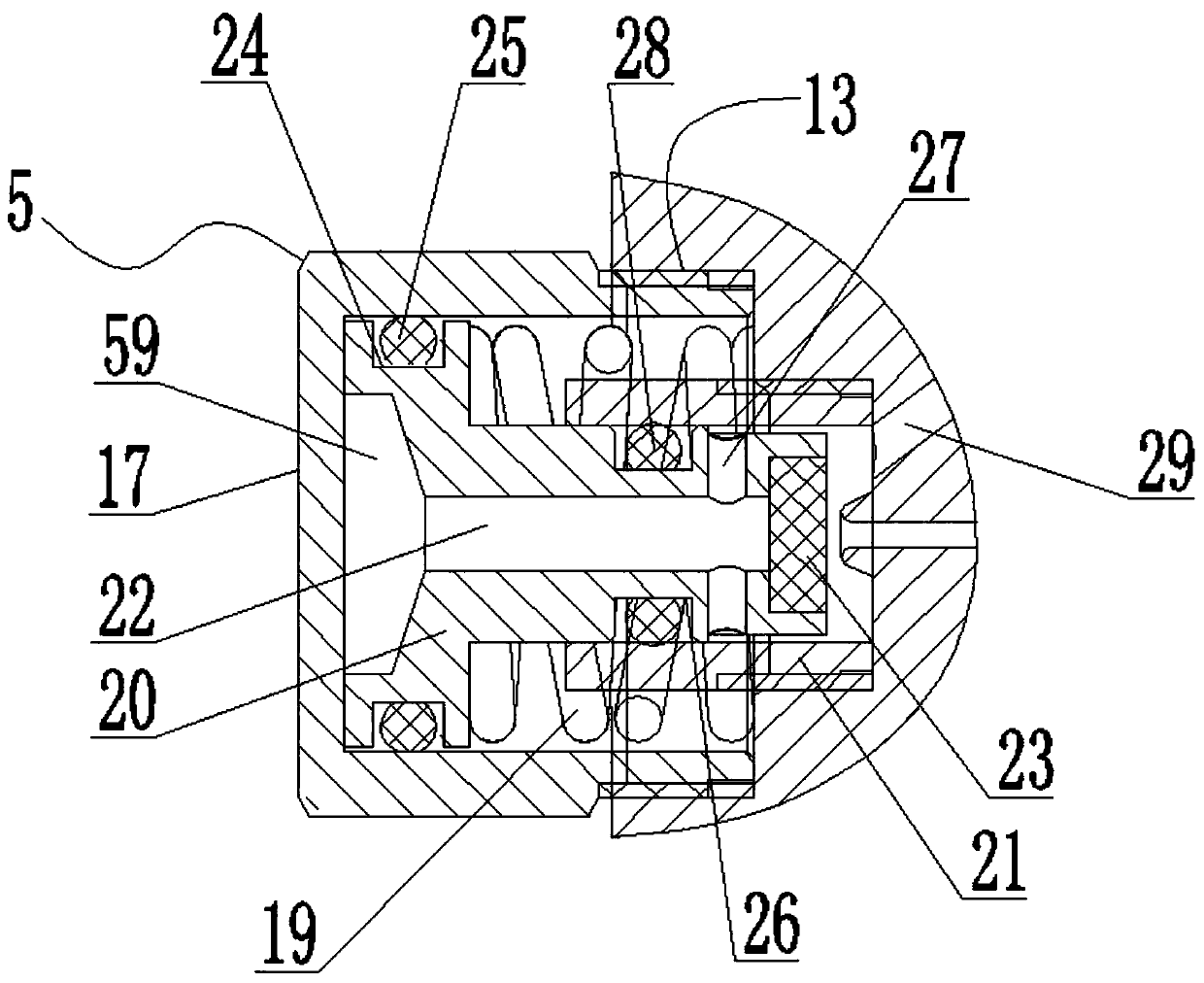

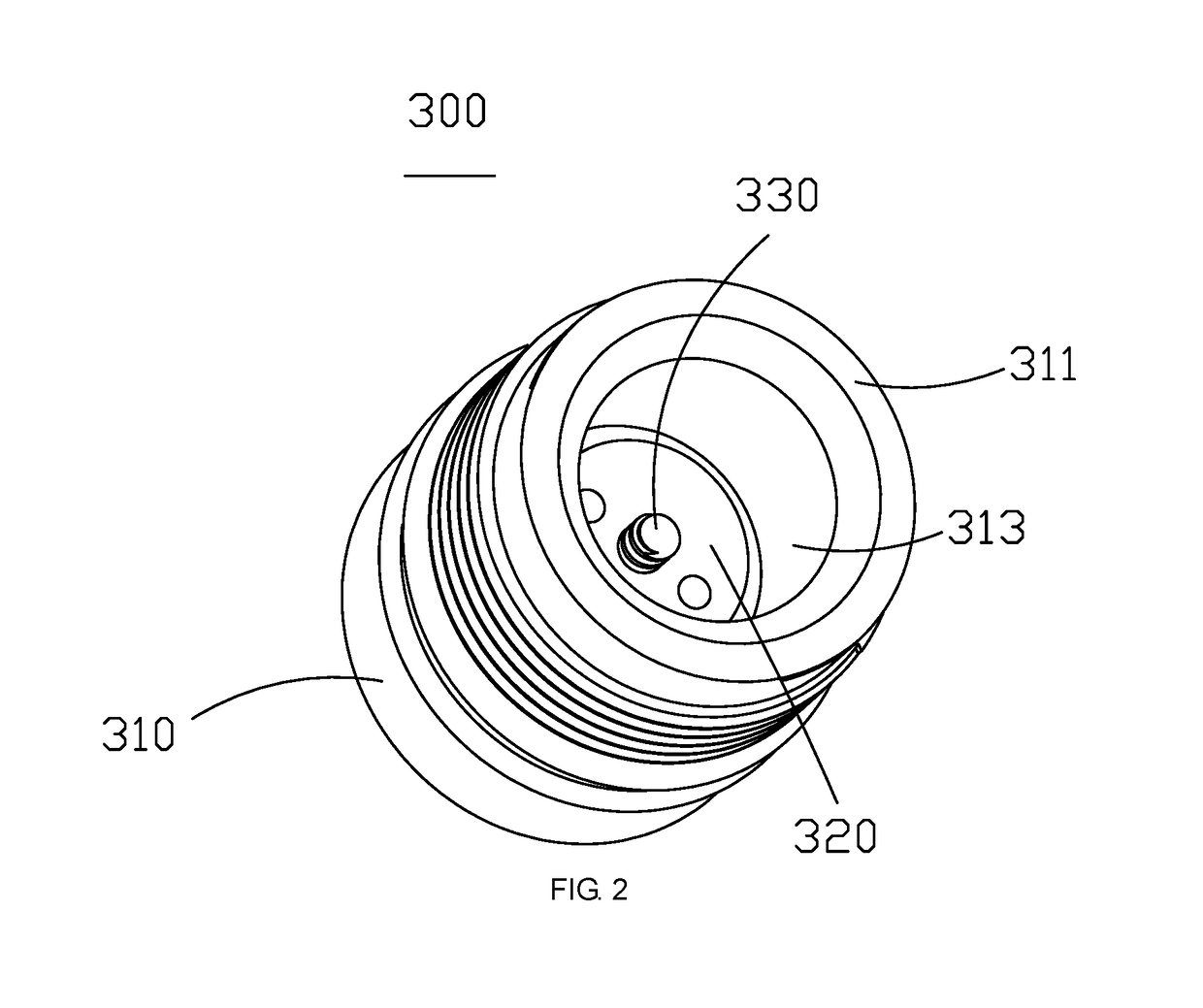

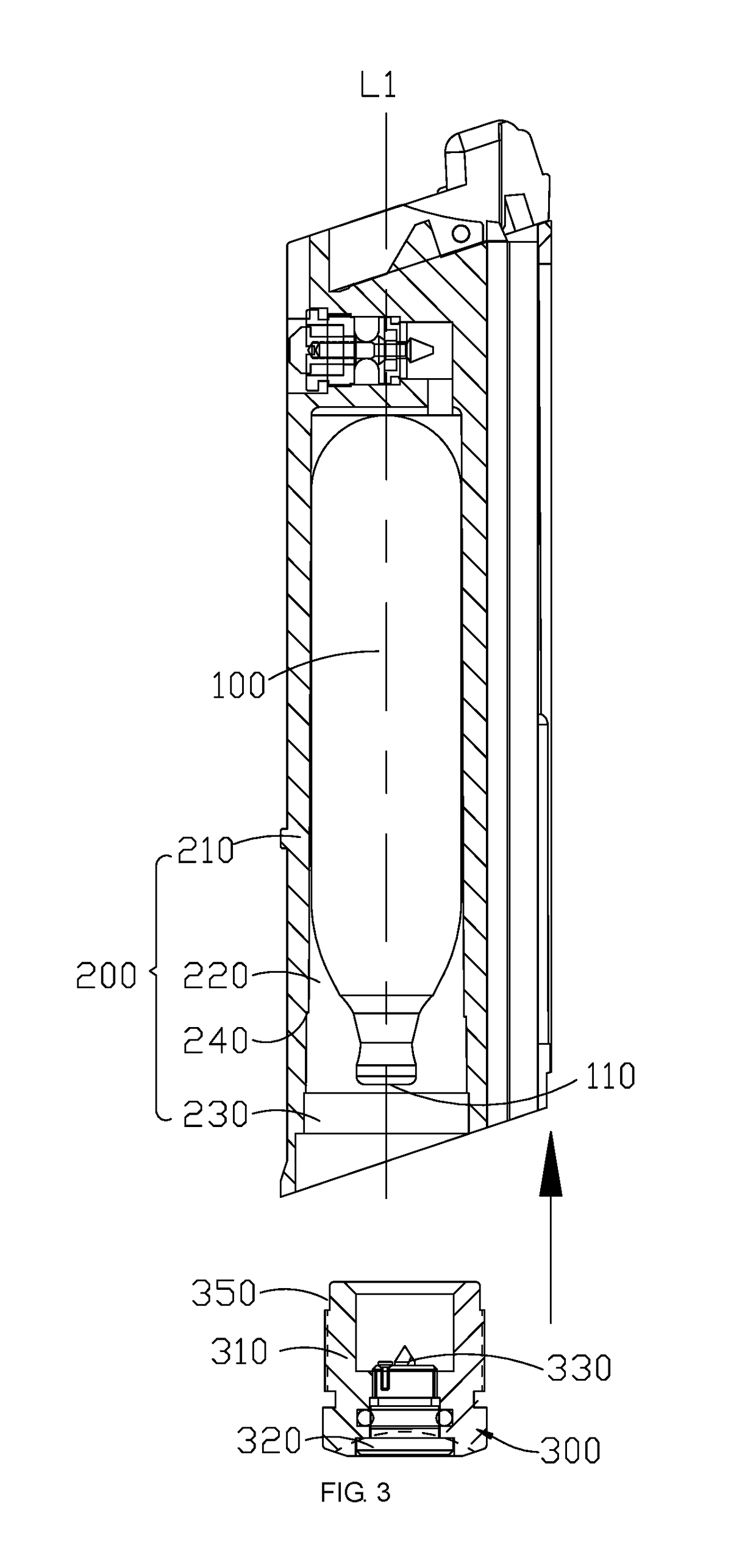

Piercing device for gas bottle, magazine and pistol comprising the same

A piercing device is provided, which comprises a housing movable with respect to a gas bottle holder having a gas bottle held therein; a piercing element received in the housing and configured for piercing into a sealing membrane of the gas bottle; and a stressing element, received in the housing; the piercing element being fixed on one end of the stressing element that is close to the gas bottle; the stressing element being capable of synchronously rotating along with the housing for being inserted into the gas bottle, or individually rotating and moving with respect to the housing for pushing the piercing element to pierce into the sealing membrane or releasing gas inside the gas bottle.

Owner:YU FUNG WAN CONNIE

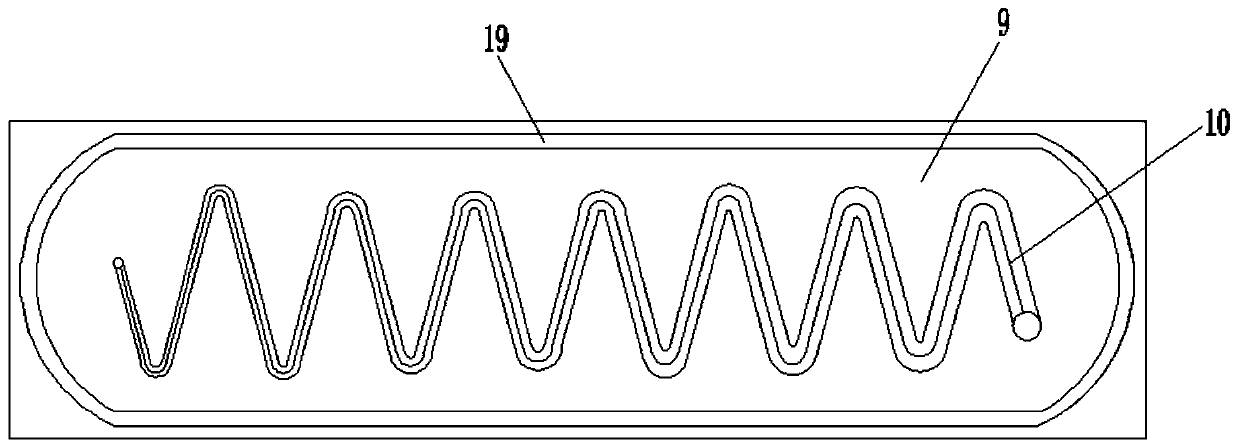

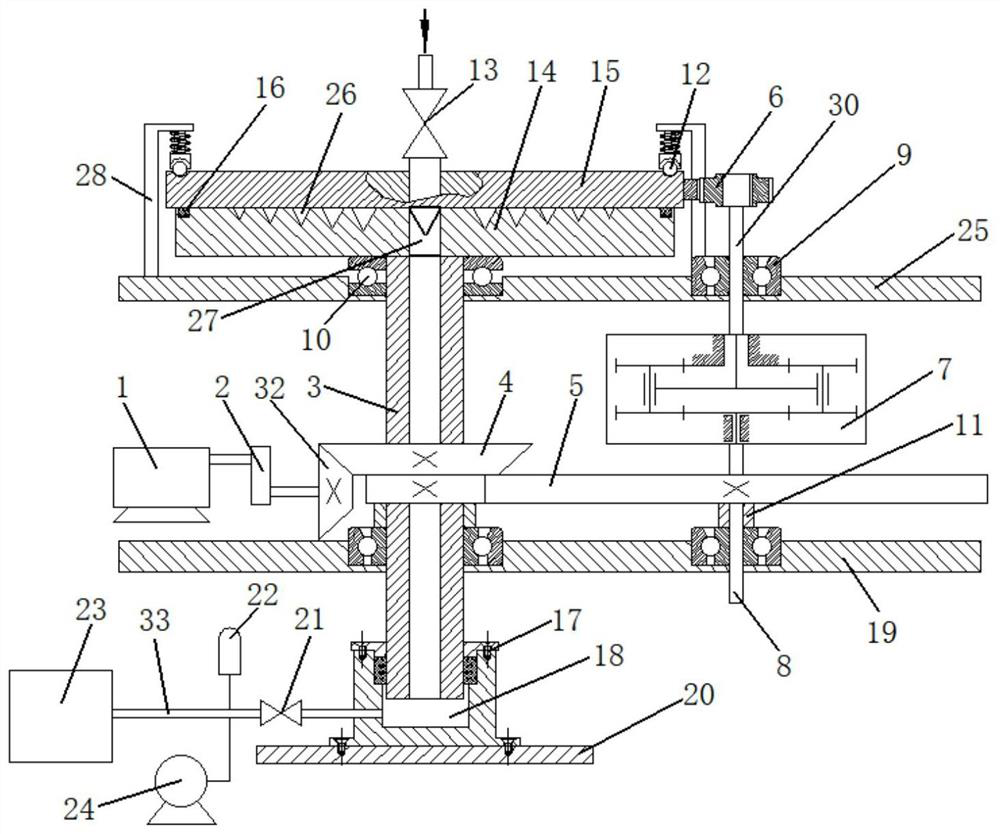

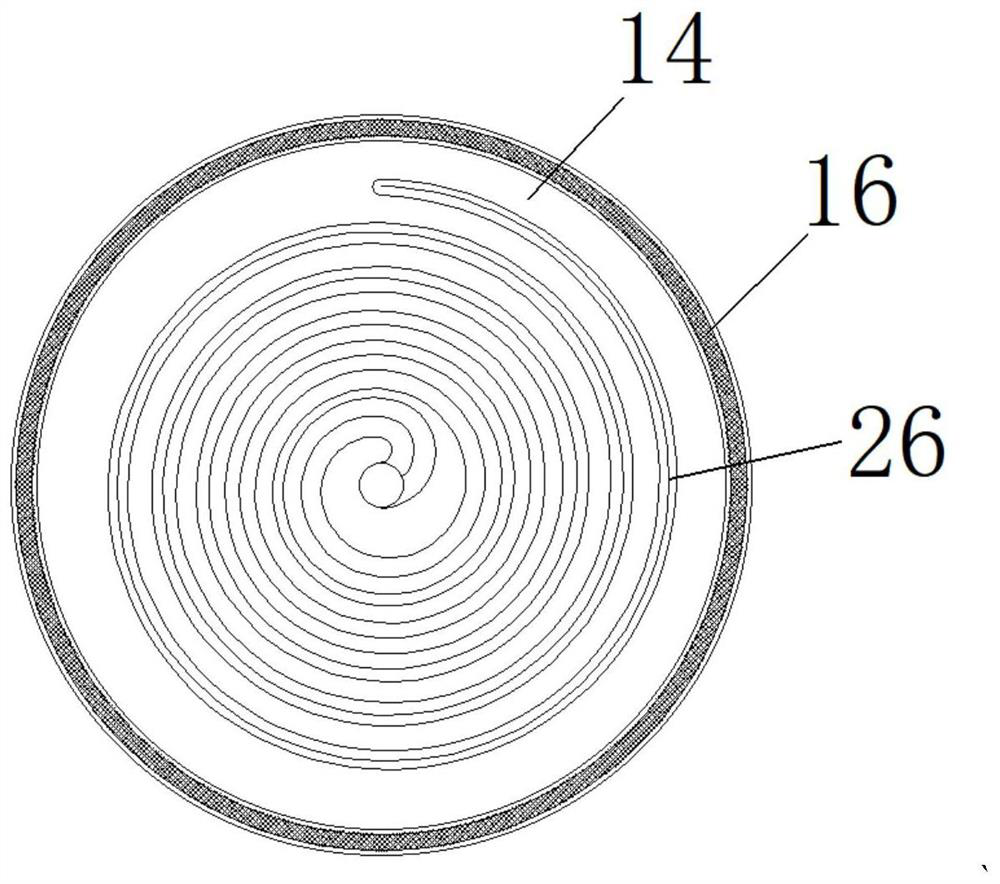

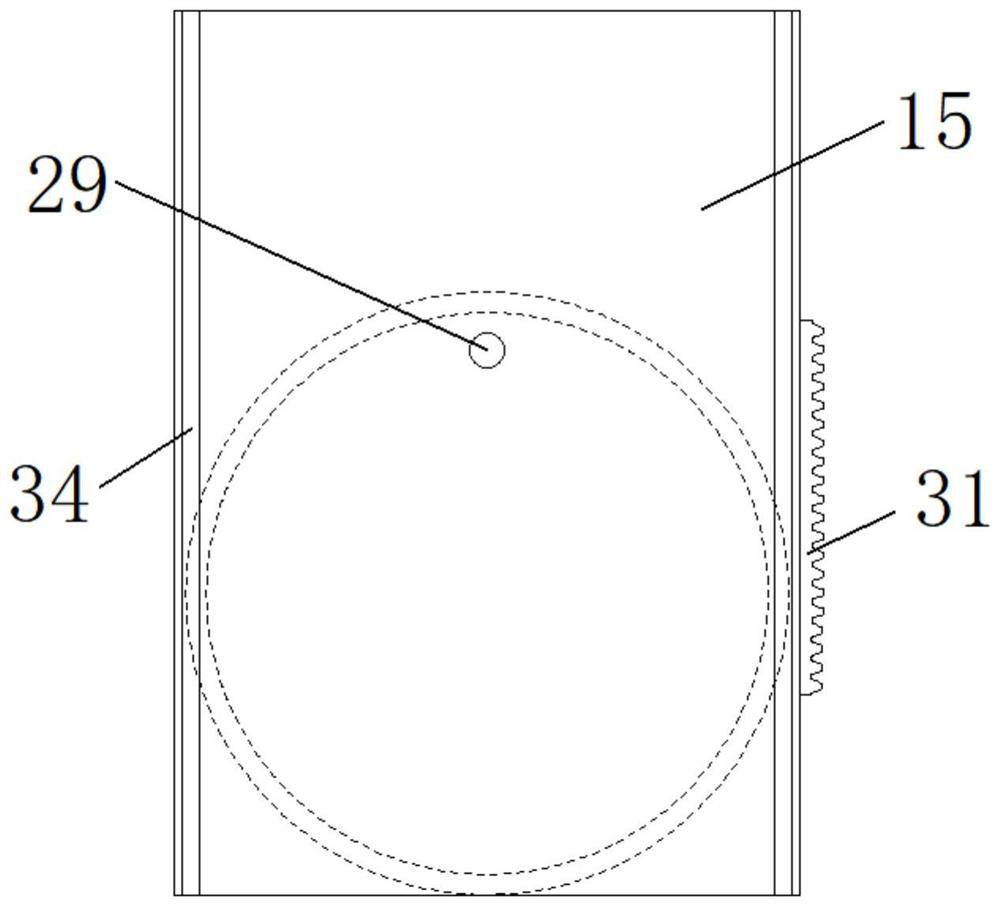

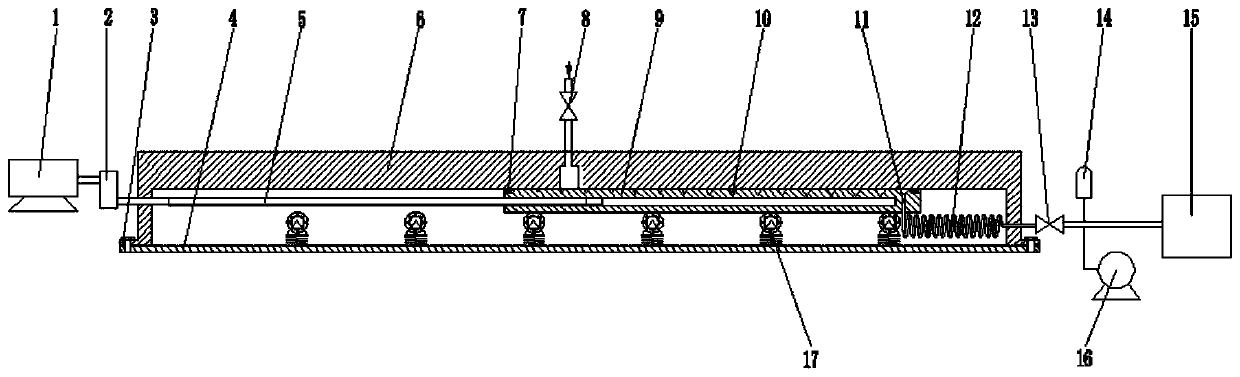

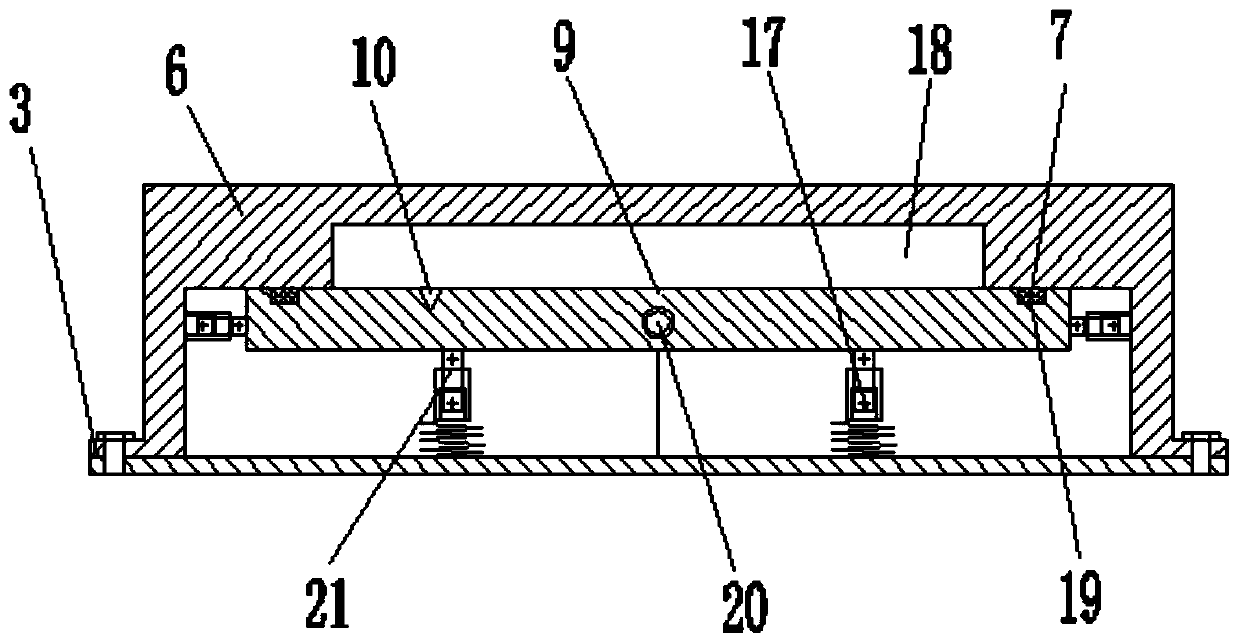

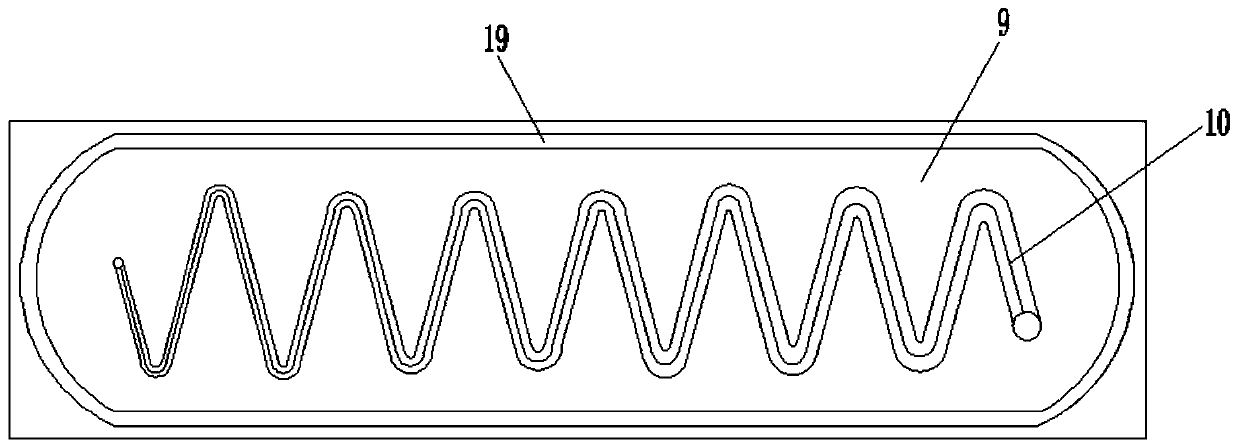

Serpentine mass spectrometer continuous variable-pressure sampling device and method

ActiveCN110071031ARealize online continuous sampling functionOvercoming the Insufficiency of Intermittent SamplingSamples introduction/extractionInlet valveDrive motor

The invention discloses a serpentine mass spectrometer continuous variable-pressure sampling device which comprises a shell and a mass spectrum system, wherein an inner plate with a serpentine grooveon the upper surface is slidably mounted in the shell, the cross-sectional area of the serpentine groove is gradually increased from an air inlet end to an air outlet end, an air outlet of the serpentine groove penetrates through the side wall of the shell through a connecting pipeline to be connected with the mass spectrum system, the lower surface of the inner plate is supported by a spring anda bearing, the upper surface of the inner plate is tightly attached to the surface of the inner upper wall of the shell with a vent groove, an air inlet of the vent groove penetrates through the upperwall of the shell to be connected with an air inlet pipeline and an air inlet valve, and a driving motor drives the inner plate to slide in the shell through a screw mechanism; the invention has compact structure and good air tightness, and has continuous online sampling capability for analyzed gas; and by a serpentine arrangement and the inner plate sliding within the shell, the length and cross-sectional area of the gas path of the serpentine groove can be changed, thereby having the capability of high-precision sampling analysis of large-range variable-pressure gas.

Owner:NORTHEASTERN UNIV LIAONING

Hydraulic gas storage cylinder

The hydraulic gas storage cylinder is one stable gas storing and supplying apparatus with stable gas pressure and high fuel gas purity. It consists of gas storing cavity, water pressure cavity, and water or solution. There are partition board set between the gas storing cavity and water pressure cavity, gas inlet pipe, gas outlet pipe and by-pass pipe in the top of the gas storing cavity, water inlet pipe and overflow pipe in the top of the water pressure cavity, and water draining pipe in the lower part of the water pressure cavity.

Owner:冯义华

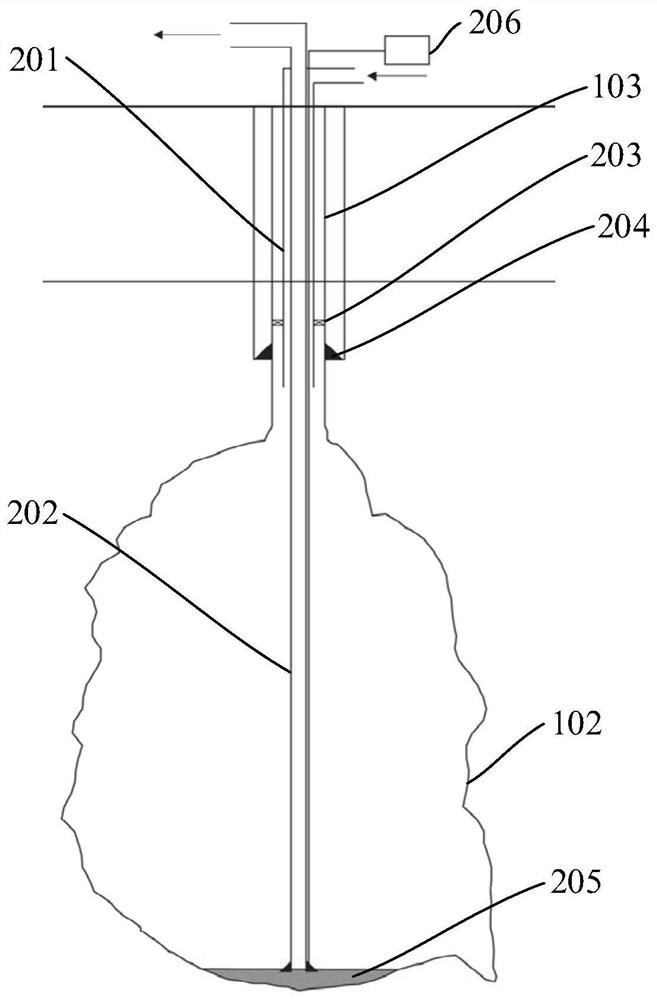

Continuous cyclic drilling process applicable to air drilling

ActiveCN103046883BEffective control of equivalent circulation densityEquivalent circulating density smooth and normalConstructionsFlushingWell drillingCheck valve

The invention discloses a continuous cyclic drilling process applicable to air drilling. The process includes the steps: a valve plate A (7) of a center check valve (2) is provided with a sealing portion A, a valve body A (6) is provided with a sealing match portion A, a valve plate B (12) of a lateral vertical check valve (3) is provided with a sealing portion B, and a valve body B (11) is provided with a sealing match portion B. During normal drilling operation, a pipeline A is connected with the center check valve (2) to supply air to a drill stem; and when the drill stem needs to be demounted, a pipeline B is connected to the lateral vertical check valve (3) to supply air to the drill stem. The continuous cyclic drilling process applicable to air drilling has the advantages that equivalent cycling density of circulation air of a well can be effectively controlled, and stability in well pressure can be effectively maintained. Drilling time is shortened, and the continuous cyclic drilling process applicable to air drilling is significant to reduction of drilling cost.

Owner:SICHUAN OUXUN ENERGY ENG TECH

A V-shaped Diesel Engine Constant Pressure Sequential Supercharging System

ActiveCN104141529BImprove compactnessReduced exhaust flow lossesInternal combustion piston enginesExhaust apparatusSingle stageTurbocharger

The invention discloses a constant pressure sequential turbo-charging system of a V-shaped diesel engine. The constant pressure sequential turbo-charging system comprises two columns of air cylinders composed of multiple air cylinders, multiple air exhaust branches corresponding to the multiple air cylinders, a constant pressure exhaust manifold, a shared air inlet box, a first turbocharger, a second turbocharger, an air cooler, an air inlet stop valve and an exhaust stop valve. The constant pressure sequential turbo-charging system is characterized in that the two columns of air cylinders share the same shared air inlet box; the constant pressure exhaust manifold is connected with the air exhaust branches corresponding to the air cylinders to form a loop. In addition, the invention further provides the design of the shared air inlet box. The shared air inlet box comprises a shared air inlet cavity, cylinder cover high-temperature water discharge header pipes and a cylinder cover high-temperature water inlet header pipe. The constant pressure sequential turbo-charging system can improve the performance of full working conditions of the single-stage high-pressure-ratio diesel engine and is compact in structure, so that the overall size of the diesel engine is controlled.

Owner:中国船舶集团有限公司第七一一研究所

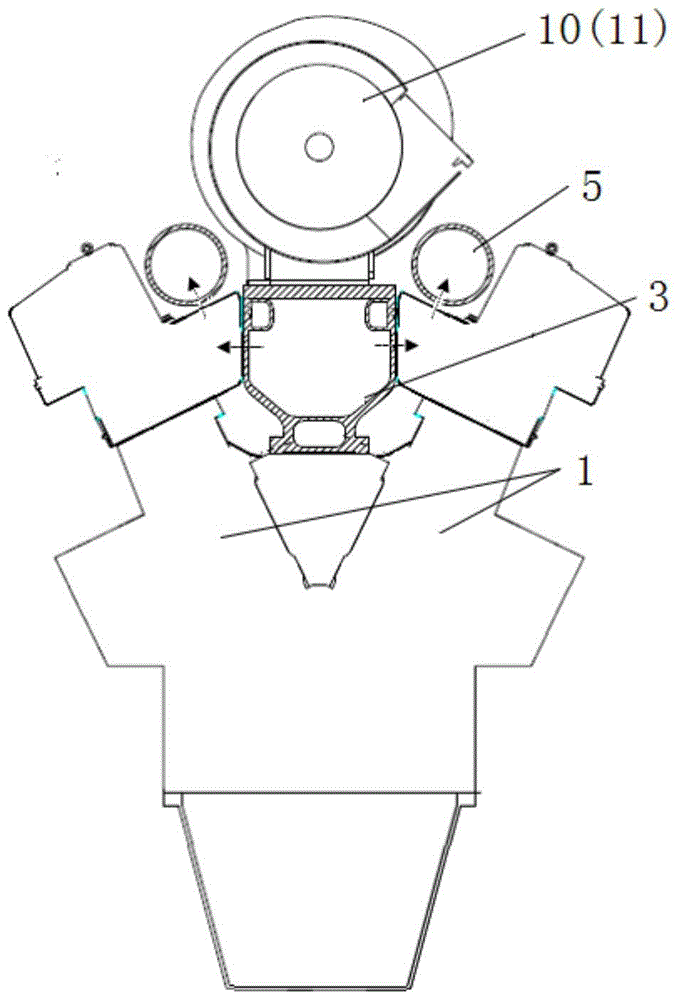

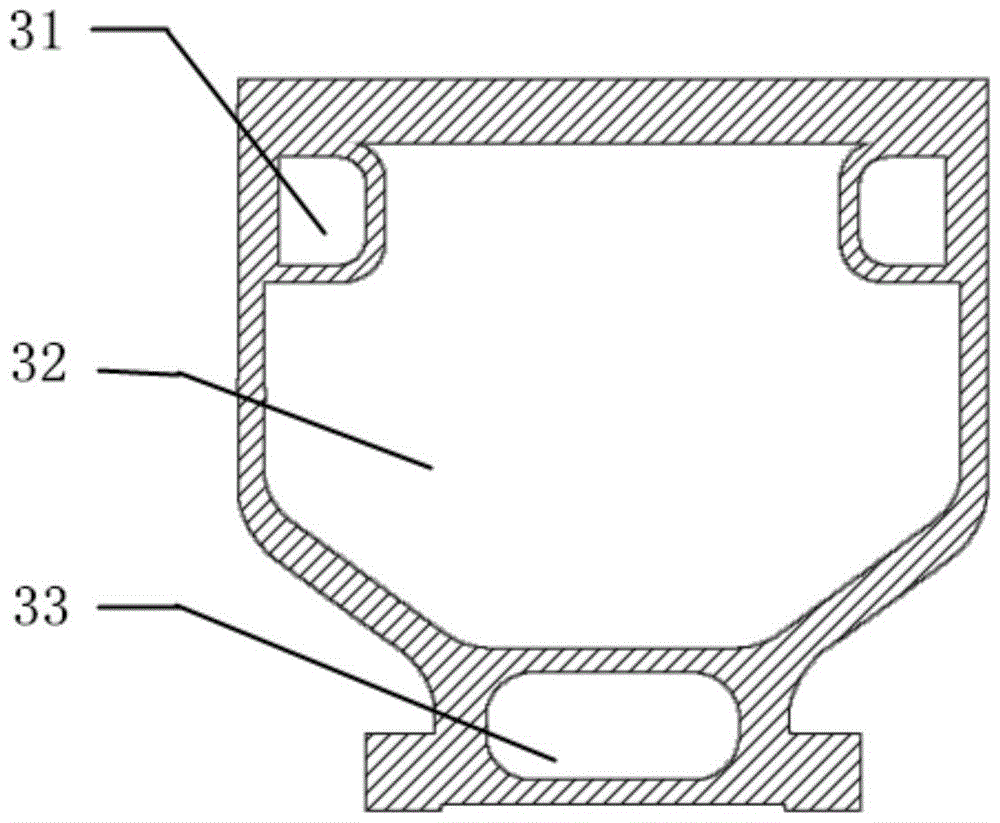

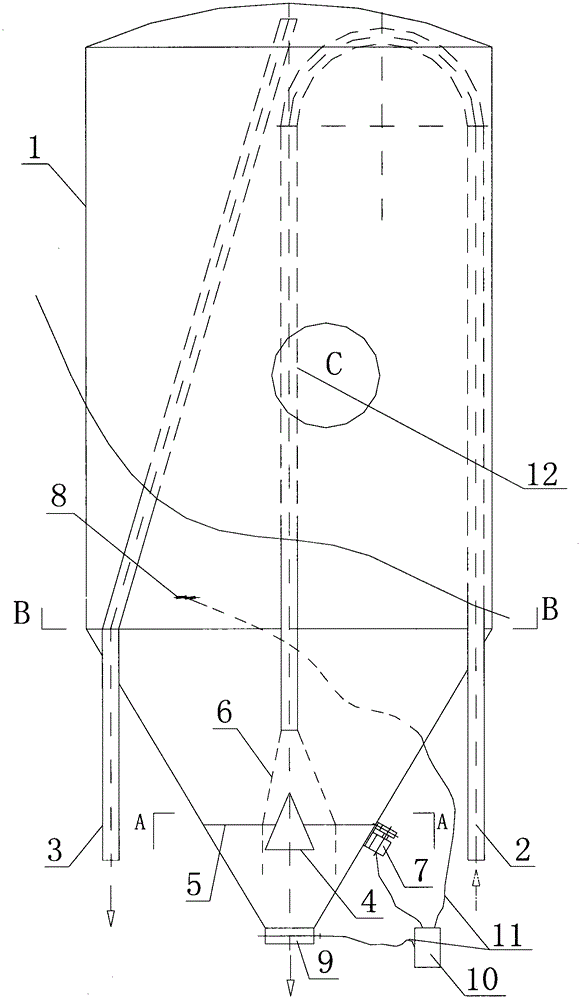

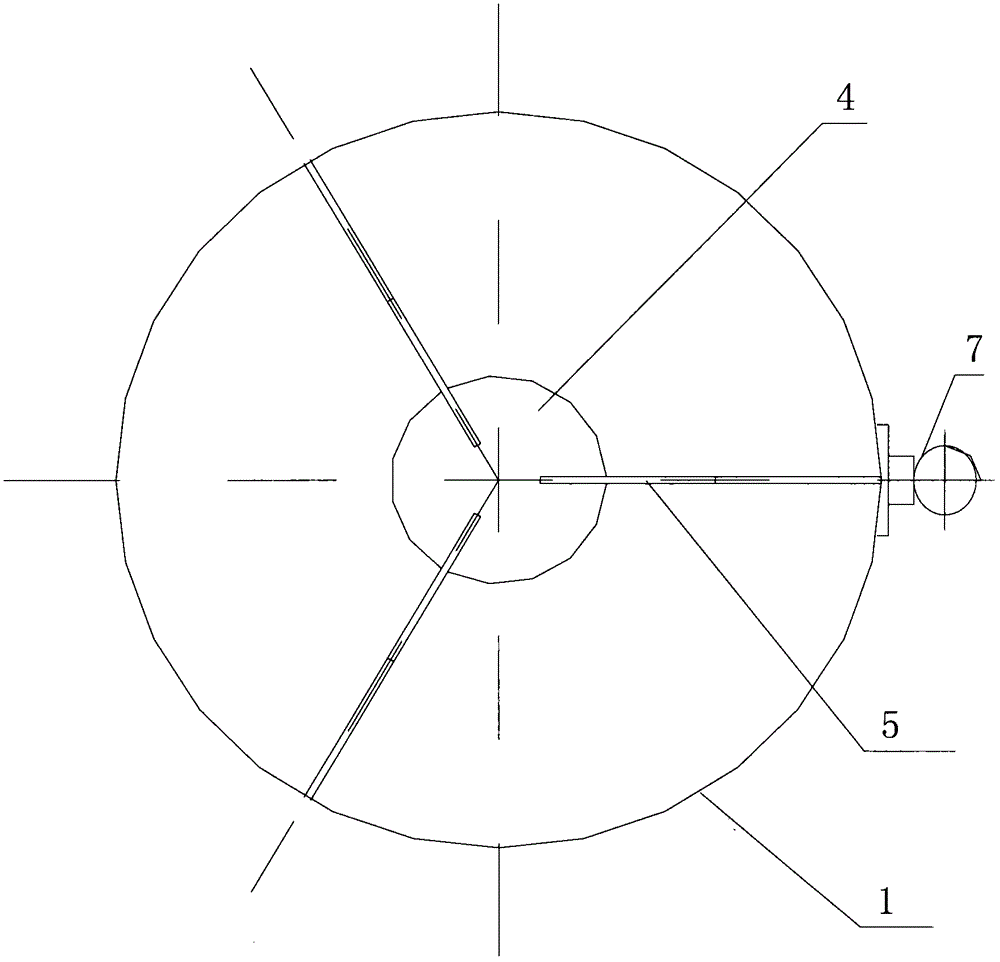

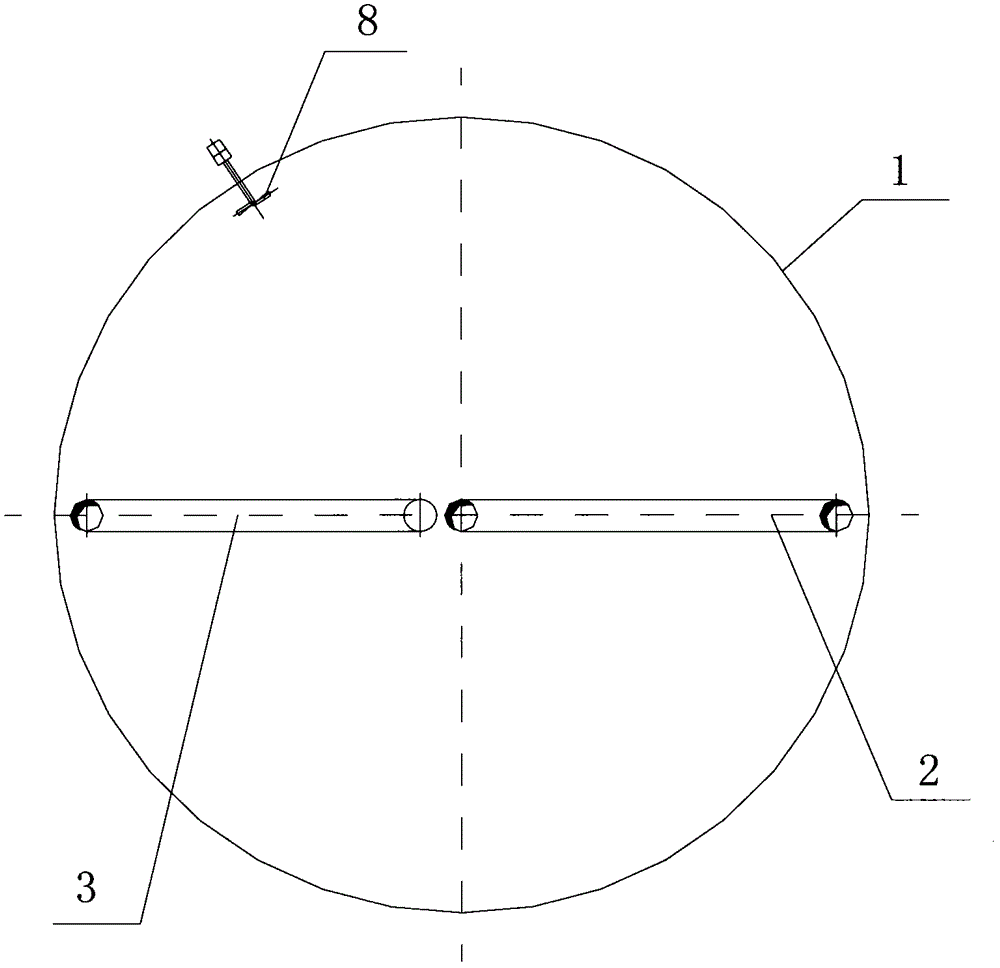

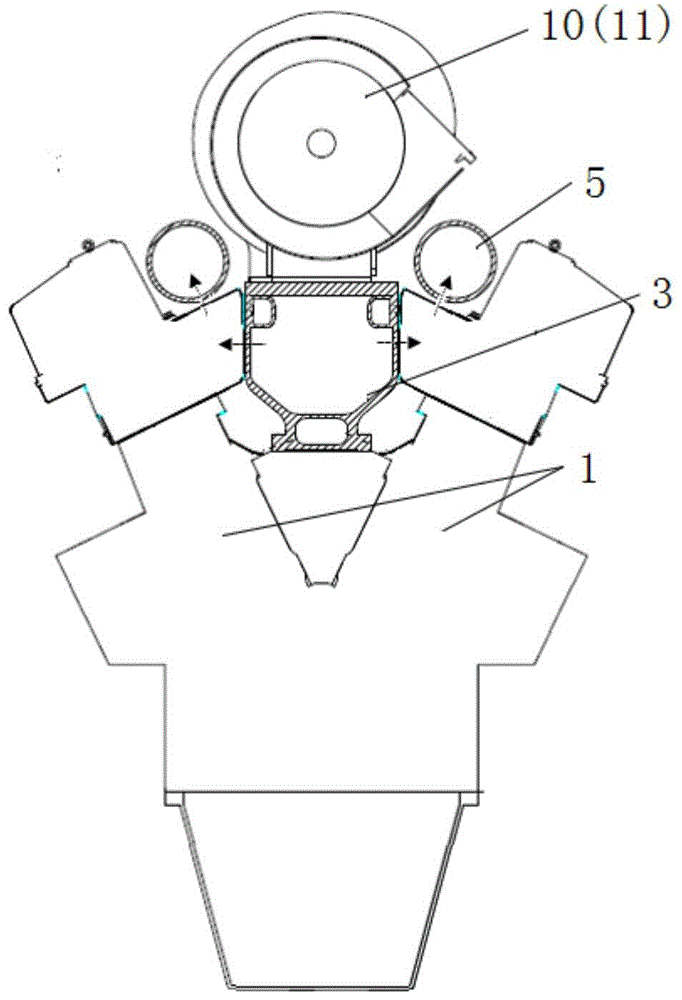

Method for manufacturing dry-mixed mortar anti-segregation silo

The invention provides a method for manufacturing a dry-mixed mortar anti-segregation silo. The dry-mixed mortar anti-segregation silo is composed of a silo body (1), a feed pipe (2), an air outlet pipe (3), an arch breaking cone (4), an arch breaking cone support (5), an arch breaking chain (6), a vibrator (7), a level meter (8), a discharge port (9), a control system (10) and wires ((11). The feed pipe (2) of the silo is arranged in a tank body in an inverted-U shape. A plurality of openings (12) are evenly distributed in the pipe wall of a descending section of the feed pipe (2). The arch breaking cone (4) is arranged below the bottom end of the descending section of the feed pipe. The arch breaking cone (4) is fixed into the silo body (1) through the arch breaking cone support (5). The upper end of the arch breaking chain (6) is fixed to the outer side of the bottom end of the descending section of the feed pipe (2). The lower end of the arch breaking chain (6) penetrates through the middle position of the arch breaking cone support (5) and is freely suspended. The air outlet pipe (3) is obliquely arranged in the silo body. The level meter (8) is mounted in the position, close to a cone, of the outer side of the silo body (1) and connected with the control system (10) and the discharge port (9) through the wires ((11). By adopting the dry-mixed mortar anti-segregation silo, the segregation phenomenon happening to dry-mixed mortar can be effectively avoided.

Owner:BEIJING BUILDING MATERIALS ACADEMY OF SCI RES

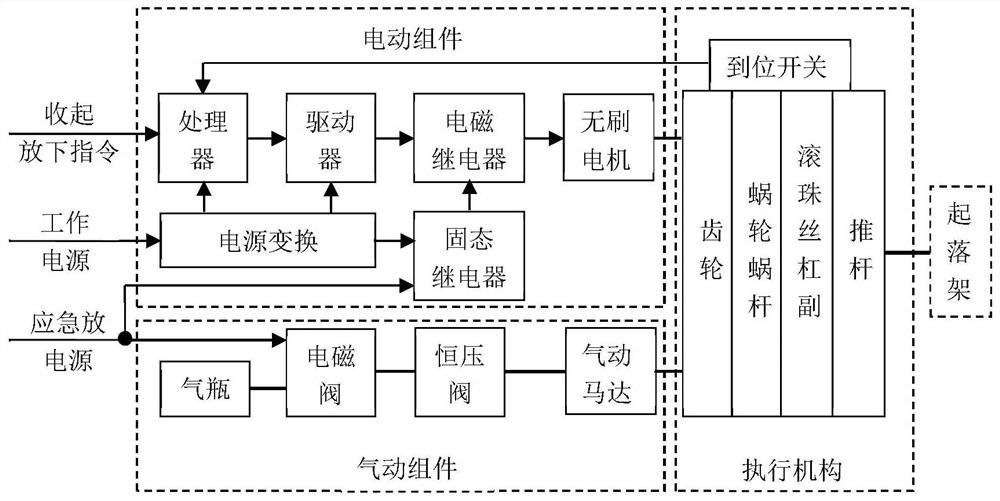

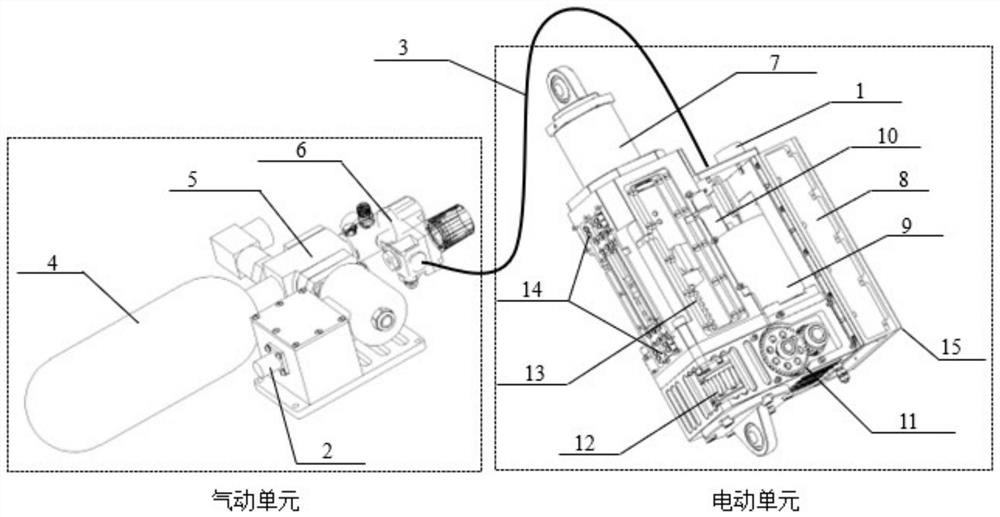

Electric and gas heterogeneous redundant unmanned aerial vehicle undercarriage folding and unfolding actuator cylinder and working method

The invention discloses an electric and gas heterogeneous redundant unmanned aerial vehicle undercarriage folding and unfolding actuator cylinder and a working method, belongs to the technical field of aircraft undercarriages. The actuator cylinder takes an electric unit as a main working channel and a pneumatic unit as an emergency auxiliary channel. Under the normal working condition, a controller controls a motor to rotate after receiving an instruction, the motor drives a push rod to move in the direction required by the instruction through a transmission assembly so as to drive an undercarriage to move till the undercarriage reaches the target position, the motor is controlled to stop rotating, and the undercarriage is locked in place. When the electric unit breaks down, a flying pipe computer starts an emergency discharge source, an electromagnetic valve opens a gas cylinder to output high-pressure gas, a pneumatic motor starts to work, a pneumatic motor drives the push rod to move through the transmission assembly, and then the undercarriage is driven to move. According to the device, when the electric unit breaks down, the pneumatic unit drives the undercarriage to move, and the problems that a hydraulic actuator cylinder is large in size, low in efficiency and poor in maintainability, and an electric actuator cylinder is low in reliability are effectively solved.

Owner:XIAN MICROELECTRONICS TECH INST

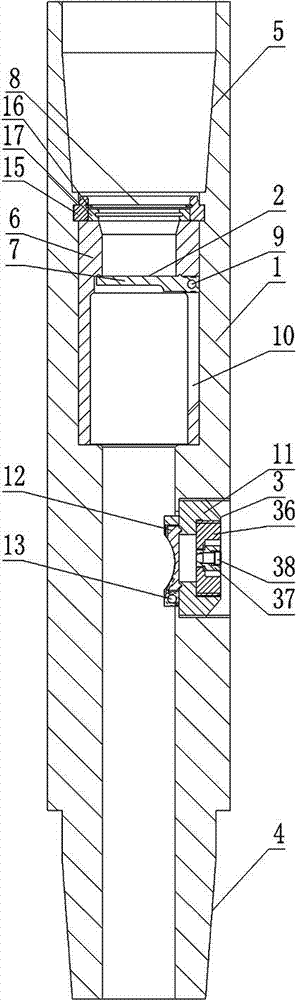

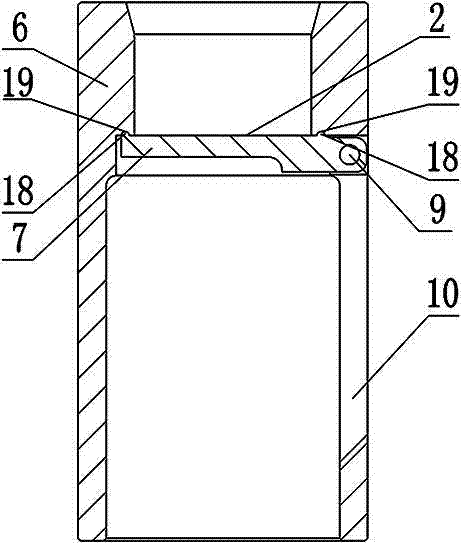

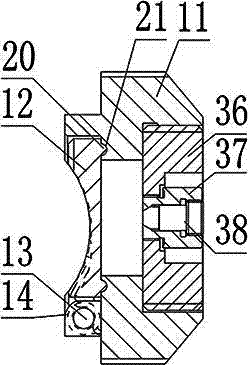

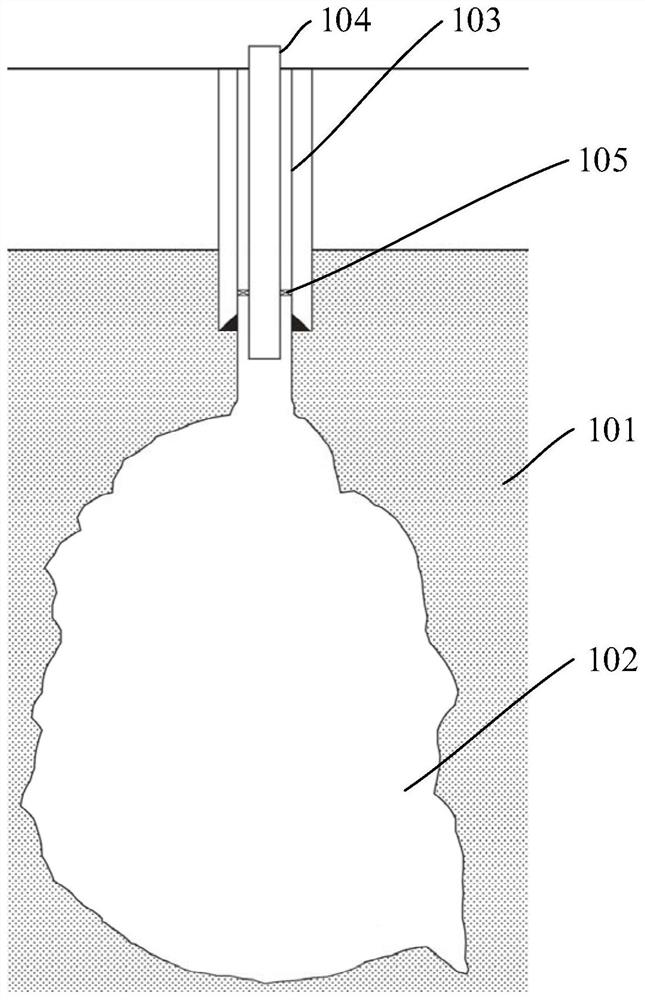

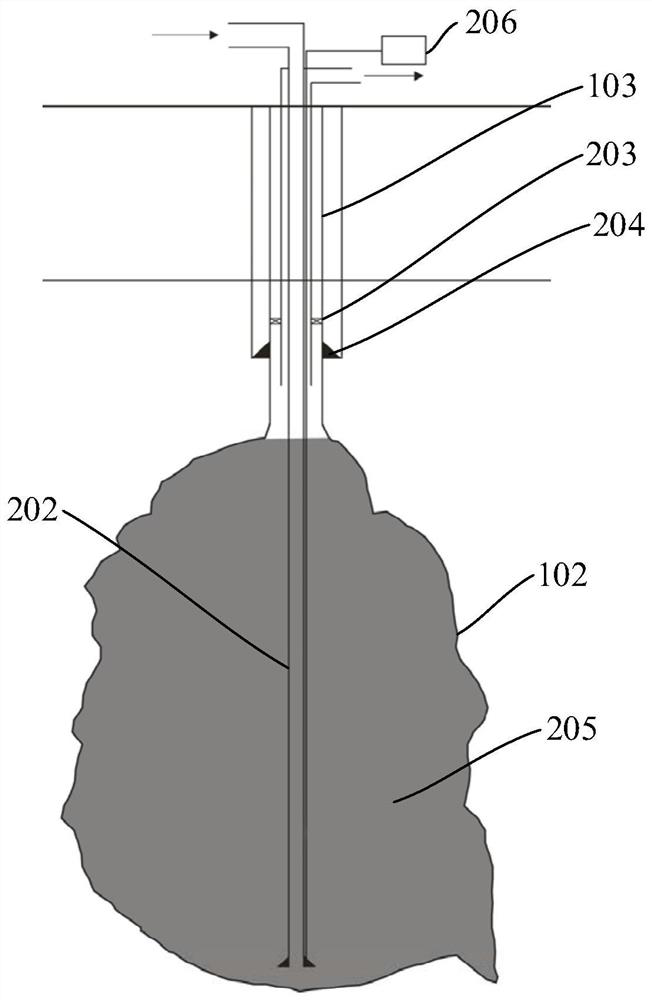

Gas injection and production device and gas injection and production method for salt-cavern gas storage

PendingCN114856507AStable gas pressureGas space reductionFluid removalNatural gas storagePetroleum engineering

The invention provides a gas injection and production device and a gas injection and production method for a salt-cavern gas storage, and belongs to the technical field of natural gas storage. The gas injection and production device of the salt-cavern gas storage comprises a gas injection and production pipe column and a brine injection and production pipe column, the upper ends of the gas injection and production pipe column and the brine injection and production pipe column are positioned on the ground; the lower ends of the gas injection and production pipe column and the brine injection and production pipe column extend into a salt cavity of the salt cavern gas storage; the salt cavity is communicated with the ground through the gas injection and production pipe column and the brine injection and production pipe column; the lower end of the gas injection and production pipe column is higher than the lower end of the brine injection and production pipe column in the vertical direction; when gas is injected into the salt cavern gas storage, the gas injection and production pipe column injects gas into the salt cavern, so that liquid in the salt cavern flows to the ground through the brine injection and production pipe column; when gas is produced from the salt cavern gas storage, the brine injection and production pipe column injects liquid into the salt cavern, so that the gas in the salt cavern flows to the ground through the gas injection and production pipe column. According to the scheme, the gas production efficiency of the salt-cavern gas storage can be improved.

Owner:PETROCHINA CO LTD

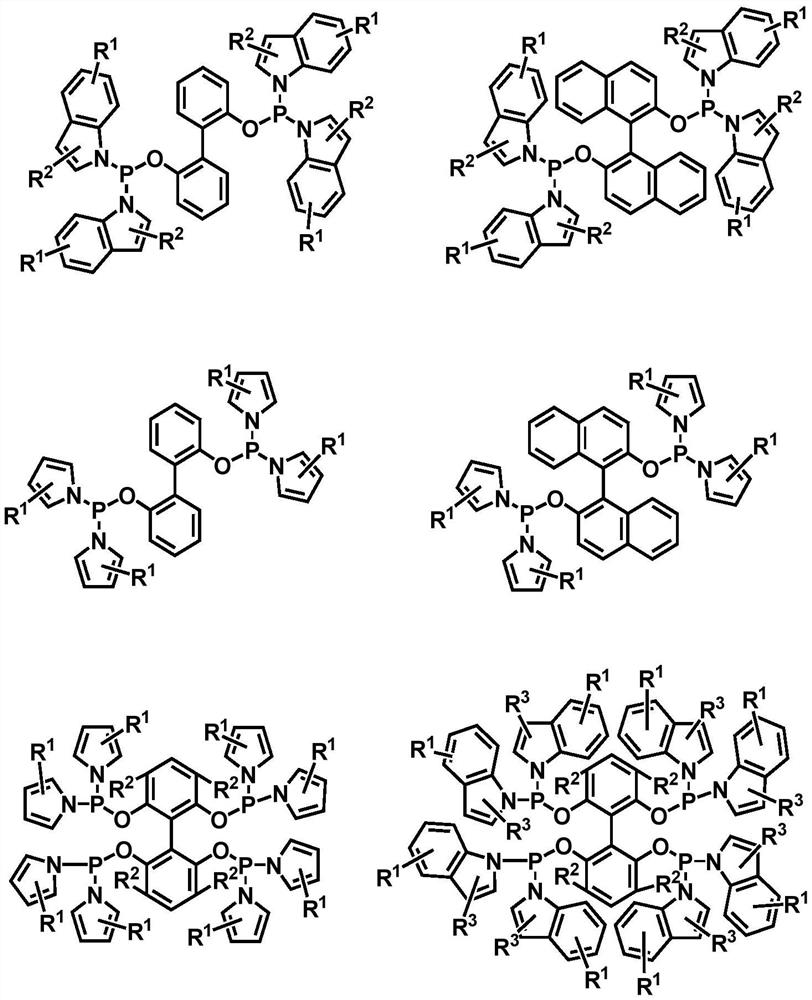

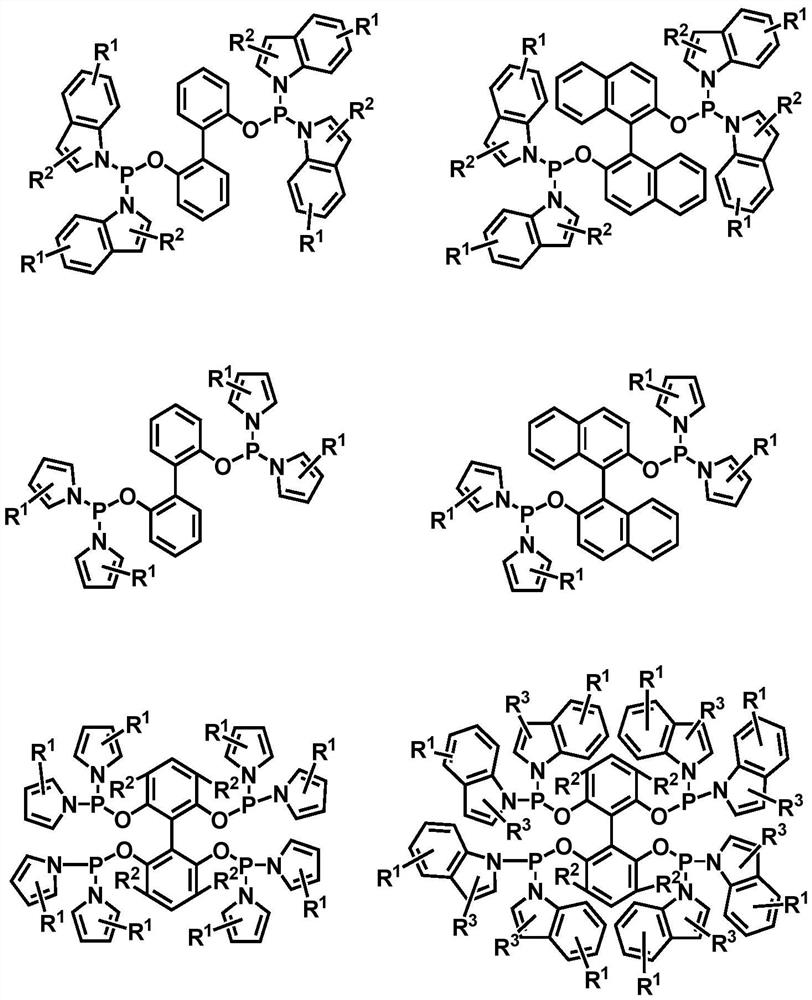

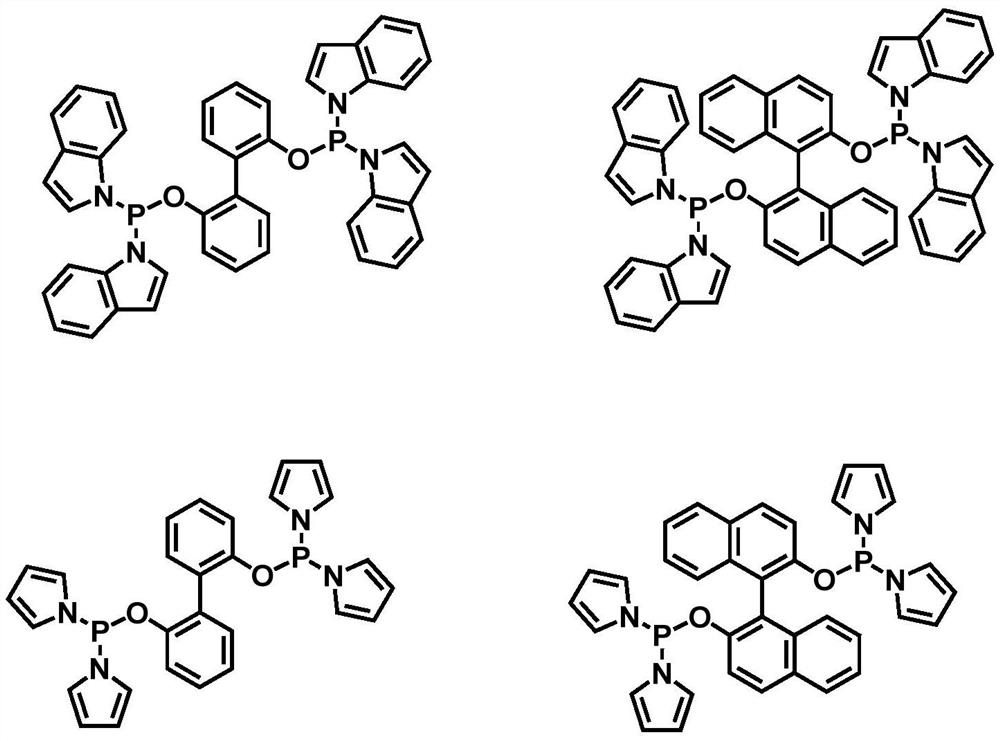

Method for preparing aldehyde by catalyzing internal olefin based on phosphoramidite phosphine ligand

ActiveCN112898140AHighly selective generationReduce dosageOrganic-compounds/hydrides/coordination-complexes catalystsCatalytic reactionsPtru catalystOrganosolv

The invention discloses a method for preparing aldehyde by catalyzing internal olefin based on a phosphoramidite phosphine ligand, which comprises the following steps: performing homogeneous reaction on the internal olefin, an organic solvent, a rhodium complex and the phosphine ligand in synthesis gas, thereby efficiently and highly selectively converting the internal olefin into the aldehyde through homogeneous hydroformylation. For example, straight-chain aldehyde can be generated from common internal olefin in a high-selectivity manner, dialdehyde can be generated from cyclic diene in a high-selectivity manner, the whole reaction system is mild in condition, fewer hydrogenation products are generated, the catalyst can be recycled, the production cost is reduced, and the production safety is improved.

Owner:SICHUAN UNIV +1

Pressure adjuster

InactiveCN110686109AStable gas pressureStable pressureOperating means/releasing devices for valvesEqualizing valvesPhysicsEngineering

The invention discloses a pressure adjuster. An adjusting handle is arranged at the top of an upper cavity of a valve body; a second-stage voltage stabilizing module is arranged under the adjusting handle; an upper spring base, an adjusting spring C and a lower spring base are arranged between the adjusting handle and the second-stage voltage stabilizing module in sequence; a pressing block in abutting fit with a valve rod at the upper end of the second-stage voltage stabilizing module is arranged in the lower end center of the lower spring base; a first-stage voltage stabilizing module and asafety valve module are assembled in cavities on the two sides of the valve body, and communicate through a communicating channel A; an intake nut is assembled in a cavity at the lower part of the valve body through threaded fit; an intake mouth is assembled in the center in the intake nut, and communicates with the communicating channel A; the first-stage voltage stabilizing module and the second-stage voltage stabilizing module communicate through a communicating channel B; and an exhaust port of the second-stage voltage stabilizing module communicates with an exhaust port on the surface ofthe valve body through an exhaust channel. The adjuster is simple in structure, excellent in voltage stabilization performance, convenient to install and maintain, small in size, low in weight and convenient to carry.

Owner:徐州鸿业仪器仪表有限公司

Pipe gas pressure stabilizing regulation system

The invention provides a pipeline gas pressure stabilization regulating system including a pressure monitoring system and a pressure regulating system, the pressure regulating system includes a fuel tank, a first pressure release valve and solenoid switch connected in turn, the solenoid switch connects to a first buffer vessel set, the other end of the first buffer vessel set connects to a regulating valve set by a second buffer vessel set, then connected to a combustor on the one hand; on the other hand the other end of the first buffer vessel set separately connects a secure boot flame and an igniter by a general pressure reducer; a gas pressure sensor in the pressure monitoring system is arranged on the top of the first buffer vessel set and the second buffer vessel set. The inventive system can reduce gas pressure wave motion for maintaining stabilization of the pipeline gas pressure.

Owner:THE QUARTERMASTER EQUIPMENT RESEARCH INSTITUTE OF THE GENERAL LOGISITIC DEPARTME

Piercing device for gas bottle, magazine and pistol comprising the same

A piercing device is provided, which comprises a housing movable with respect to a gas bottle holder having a gas bottle held therein; a piercing element received in the housing and configured for piercing into a sealing membrane of the gas bottle; and a stressing element, received in the housing; the piercing element being fixed on one end of the stressing element that is close to the gas bottle; the stressing element being capable of synchronously rotating along with the housing for being inserted into the gas bottle, or individually rotating and moving with respect to the housing for pushing the piercing element to pierce into the sealing membrane or releasing gas inside the gas bottle.

Owner:YU FUNG WAN CONNIE

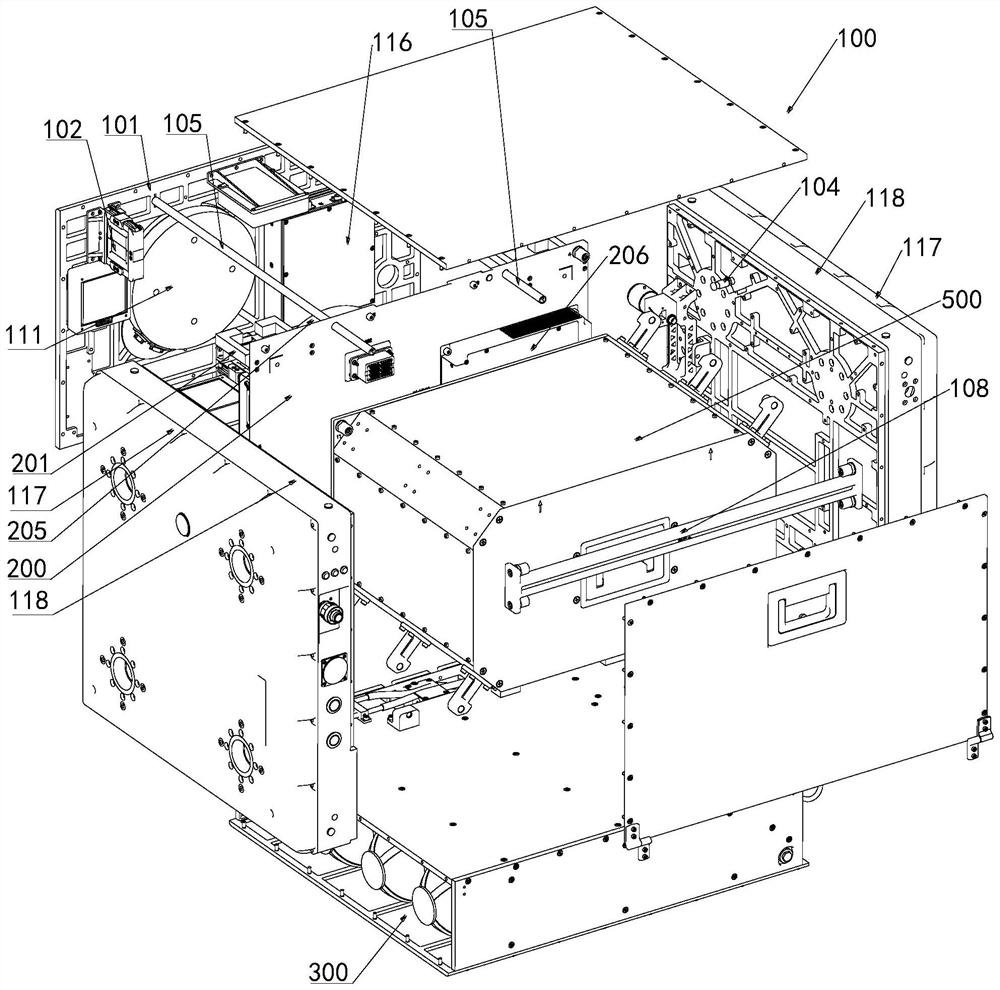

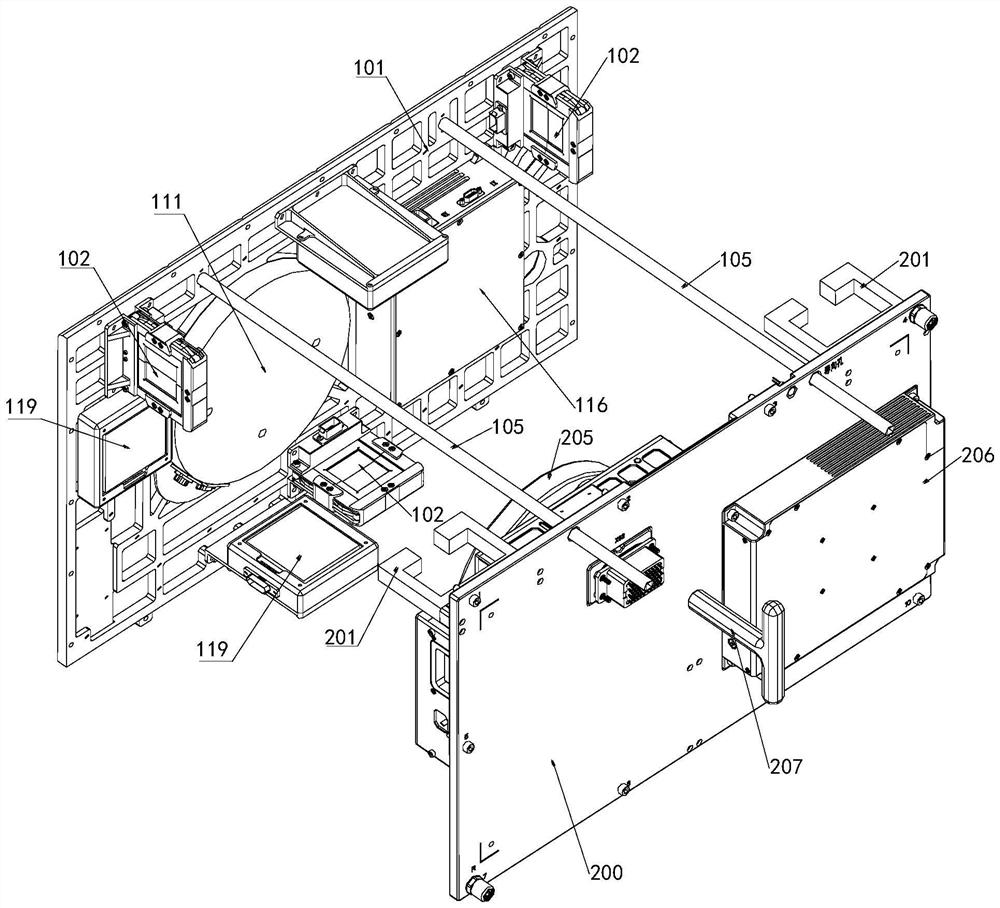

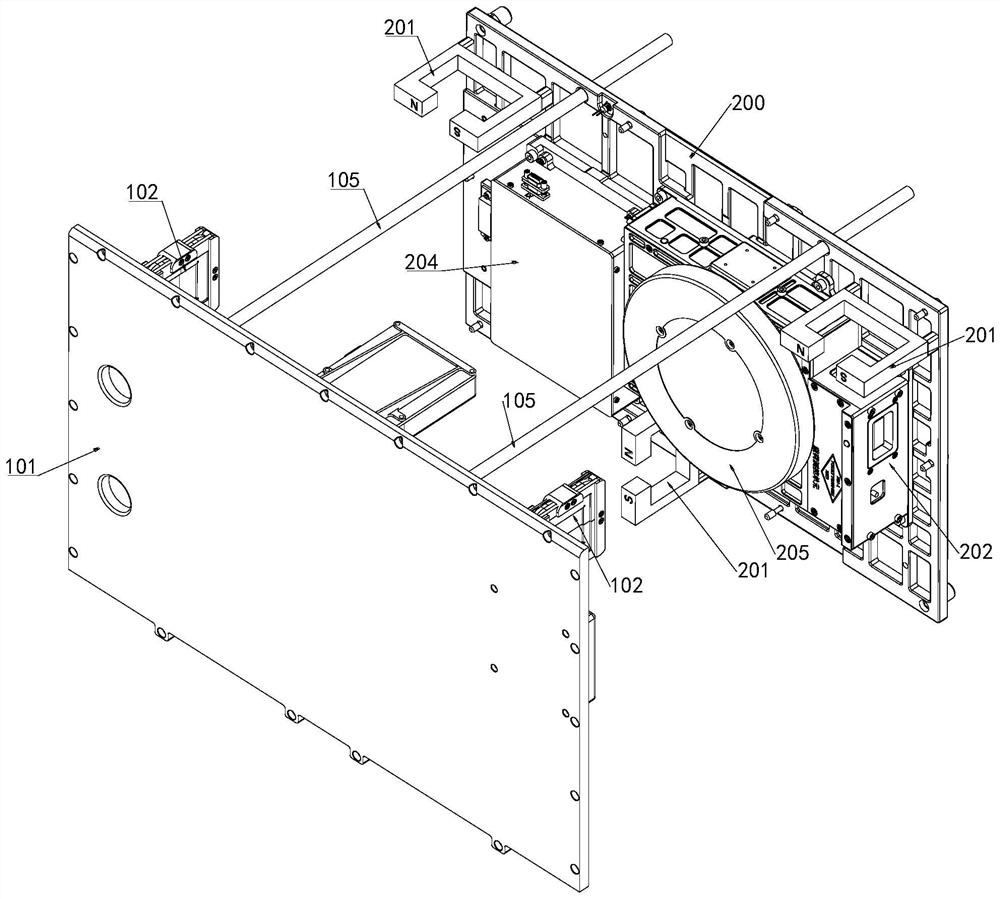

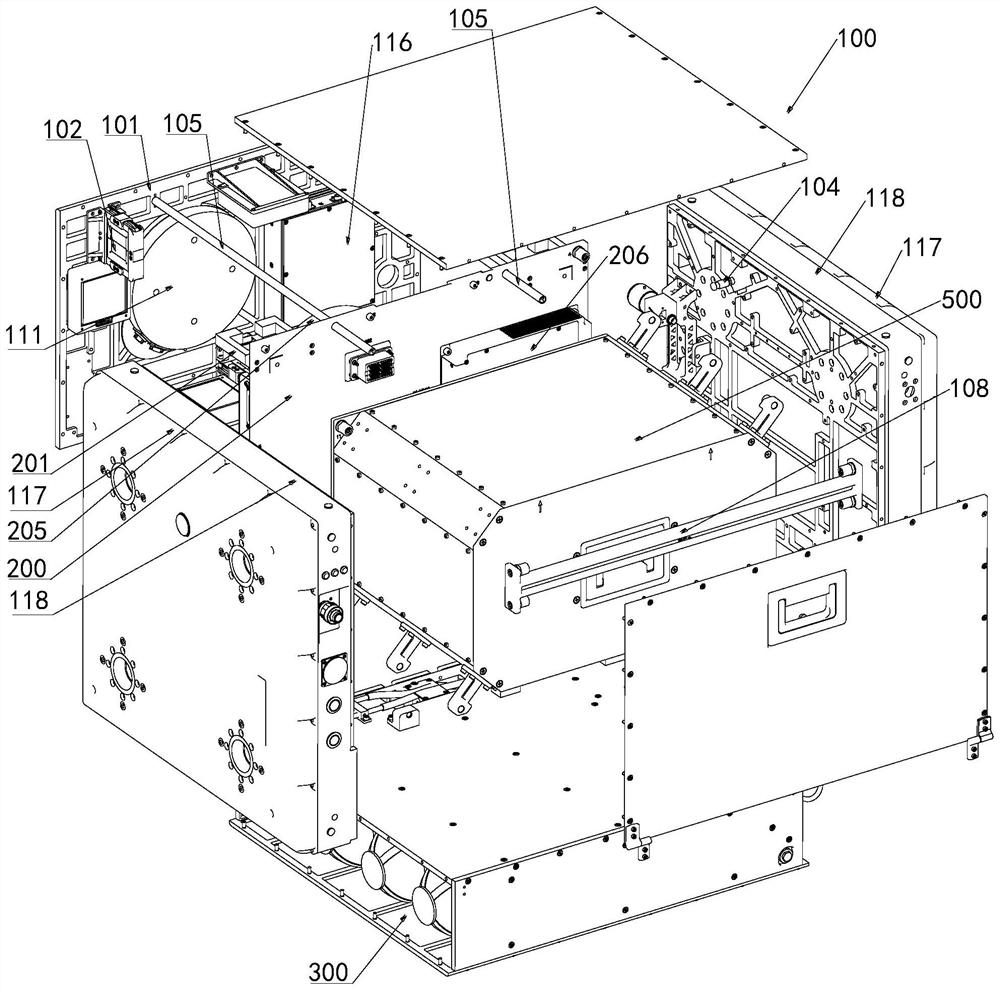

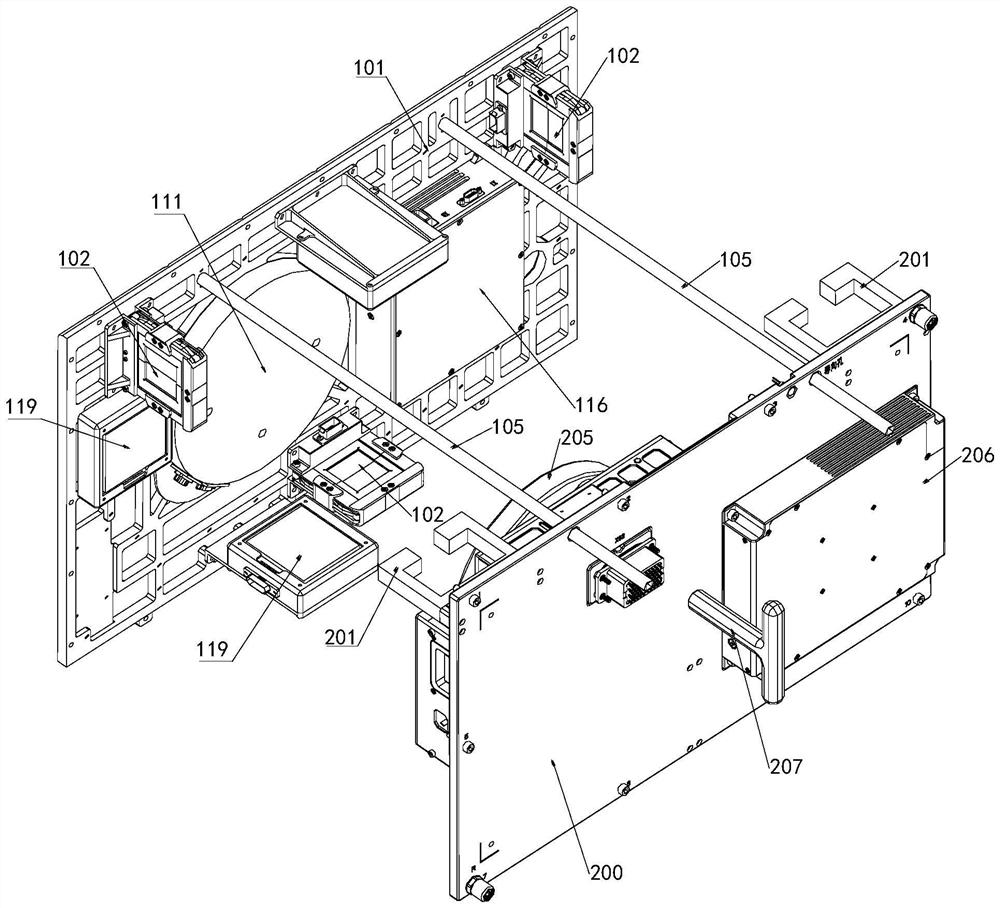

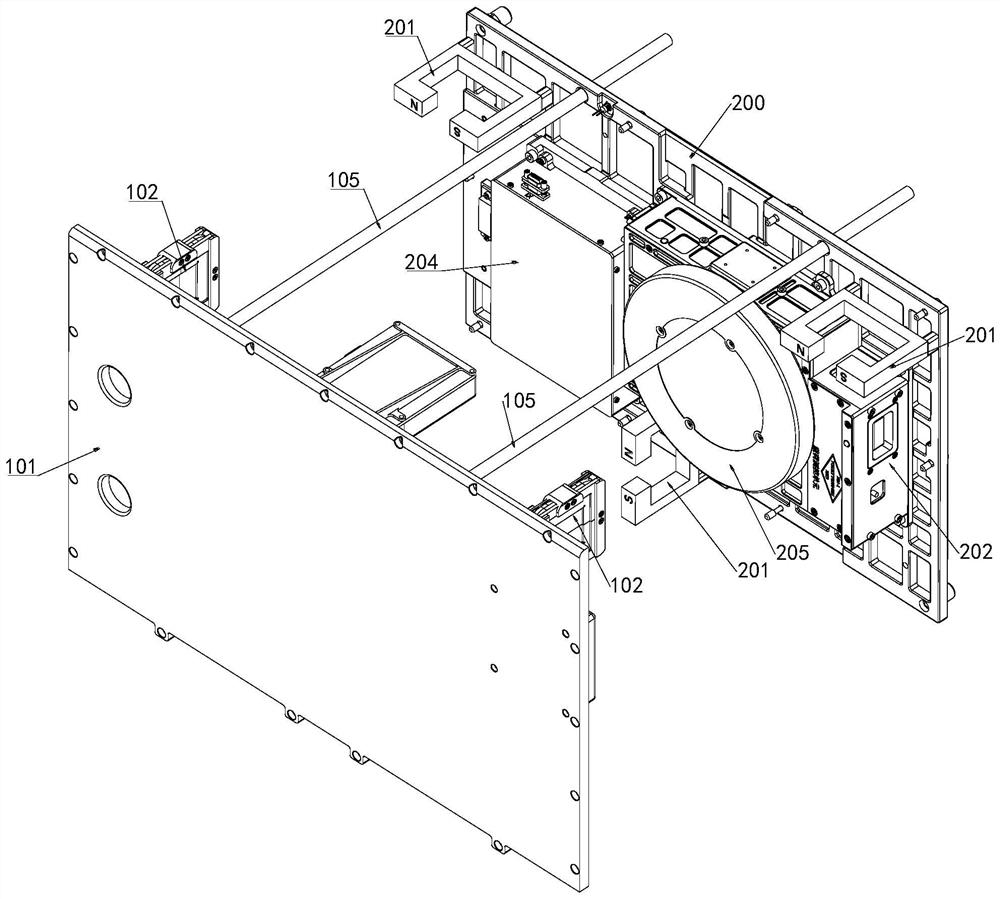

Space microgravity double-layer suspension vibration isolation device, scientific experiment cabinet and suspension method

ActiveCN114132537ASupport refactoringWith wireless communication functionCosmonautic condition simulationsEngineeringMicro gravity

The invention relates to a space microgravity double-layer suspension vibration isolation device, a scientific experiment cabinet and a suspension method.The space microgravity double-layer suspension vibration isolation device comprises a jet suspension experiment table (outer body for short) and a magnetic suspension experiment table (inner body for short), the inner body is provided with a magnet, the outer body is provided with an electromagnetic coil, the inner body is embedded into the outer body, and the magnet and the electromagnetic coil are arranged correspondingly; the inner body is controlled to suspend relative to the outer body by the acting force generated by the electrified coil in the magnetic field; a thruster is arranged on the outer body, and the thruster is used for jetting airflow to generate thrust to control the outer body to suspend. According to the invention, the double-layer non-contact movement of the outer body following the inner body is realized from the hardware level, and the disturbance of the basic environment is isolated, so that the high microgravity level is realized.

Owner:TECH & ENG CENT FOR SPACE UTILIZATION CHINESE ACAD OF SCI

Sample cracking voltage stabilizer

ActiveCN102778375BReduce pollutionReduce instabilityPreparing sample for investigationSulfurNitrogen

The invention discloses a sample cracking voltage stabilizer, comprising a high-temperature cracking furnace and a blind extension-type quartz tube, wherein an argon inlet and an oxygen inlet of the quartz tube are respectively connected with a mass flow meter, a gas buffer device composed of a cylinder, a piston and a stepping motor is arranged at the exit of the quartz tube, the exit of the cylinder is connected with a mass flow meter, a gas pressure detector is arranged in the cylinder, and all the flow meter, the detector and the stepping motor are connected with a control panel of a computer. The sample cracking voltage stabilizer can be applied in relative analytical instruments to detect the content of sulfur and nitrogen, so that the sample reaction is sufficient, air pressure and flow are stable, and therefore, the detection precision is improved, and repeatability deviation is reduced.

Owner:泰州市中环分析仪器有限公司

A common air intake box for a diesel engine

ActiveCN104265520BImprove compactnessReduced exhaust flow lossesInternal combustion piston enginesExhaust apparatusPulp and paper industryDiesel engine

The invention discloses a common inlet box of a diesel engine. The common inlet box is characterized by providing air to all cylinders of the diesel engine, and the effective airflow cross sectional area is (cylinder diameter 2 / 4*stroke) / cylinder center distance*A, wherein A is a correction coefficient; and the common inlet box comprises a common inlet cavity, a cylinder cover high-temperature water inlet main pipe and a cylinder cover high-temperature water exhaust main pipe. The common inlet box is arranged in a V angle of the diesel engine so as to improve the arrangement compactness of the diesel engine; and in addition, the cylinder cover high-temperature water inlet main pipe and the cylinder cover high-temperature water exhaust main pipe are integrated, so that the arrange compactness of the diesel engine can be further improved through the design.

Owner:中国船舶集团有限公司第七一一研究所

Device and method for measuring gas diffusion coefficient of low-strength, low-permeability coating material

ActiveCN106092826BIncrease transfer rateEffective shape measurementDiffusion analysisEngineeringGas flux

The invention provides an apparatus and a method for determining gas diffusion coefficient of a low-intensity low-permeability coating material, which relates to the coating material coefficient determination apparatus and the method thereof. The apparatus comprises two paralleled vacuum chambers of a measuring chamber and an aeration chamber which are connected through an air exhaust channel with a seal flange, the seal flange faces to one side of the aeration chamber, a disk shaped blank flange or a test sample is fixed in a sealing mode by using a flange gland and a sealing ring; an operable aeration chamber door is arranged in the aeration chamber, which is used for arranging or dismounting the blank flange or the test sample; an aeration chamber pressure gauge, an aeration pipeline having a pressure adjusting control valve and an air exhaust pipeline having an aeration chamber valve are arranged in the aeration chamber; the measuring chamber pressure gauge and the air exhaust pipeline having a measuring chamber valve are arranged in the measuring chamber, and the background leakage rate of the measuring chamber is relatively stationary. The apparatus can use a thin coating material for measurement, for the low-permeability coating material, data for stabilization of gas pressure and gas flux can be rapidly acquired, and the measurement result is accurate.

Owner:辽宁博仕创业服务中心管理有限公司

Continuous pressure variable sampling device and method for Archimedes spiral mass spectrometer

ActiveCN110057630BRealize online continuous sampling functionOvercoming the Insufficiency of Intermittent SamplingSamples introduction/extractionWithdrawing sample devicesElectric machineTransformer

Owner:NORTHEASTERN UNIV LIAONING

Gas generating agent of fire-extinguishing device and preparation method thereof

ActiveCN107445782AStable gas pressureStrong persistenceChemical industryExplosivesAdhesivePotassium nitrate

The invention provides a gas generating agent of a fire-extinguishing device and a preparation method thereof and relates to the technical field of fire fighting and fire extinguishing. The gas generating agent comprises a main component and auxiliary components, wherein the main component is prepared by the following materials in percent by weight: 60-70% of potassium nitrate, 10-20% of melamine and no less than 5% of foaming agent; and the auxiliary components comprise the following materials in percent by weight: 6-12% of adhesive and no more than 5%. The gas generating agent provided by the invention has the advantages that the components are simple, the cost is low, the generated gas is stable in pressure and strong in continuity, and the gas generation amount is large, so that the fire extinguishing efficiency of the fire-extinguishing device is high and the like.

Owner:陕西远成消防工程设备有限公司

Liquefied fuel gas system for oven

The invention relates to a liquefied fuel gas system. One end of a fuel gas main pipeline is connected with liquefied fuel gasification devices. The other end of the gas main pipeline is connected with a diffusion pipeline, and gas branch pipelines are arranged on the fuel gas main pipeline. One or more sets of liquefied fuel gasification devices are connected in parallel. Each set of liquefied fuel gasification device comprises an annular pipeline, wherein at least two liquefied fuel bottles connected through a hose are arranged on the annular pipeline, an outlet of the annular pipeline is connected with gasification equipment through a pipeline, a fuel main ball valve is arranged on a pipeline of the outlet of the annular pipeline, and a fuel gas pressure regulating valve and a pressure gauge are sequentially arranged on an outlet pipeline of the gasification equipment. A diffusion ball valve and a diffusion cap are arranged on the diffusion pipeline. The number of the fuel gas branch pipelines is the same as that of flame paths of a pot-type furnace, and the tail ends of the fuel gas branch pipelines are connected with burners. The liquefied fuel gas system has the advantages that the system can maintain stable gas pressure, the heating rate can be conveniently and accurately controlled, and meanwhile the safety performance is reliable.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

Continuous pressure variable sampling device and method for serpentine mass spectrometer

ActiveCN110071031BRealize online continuous sampling functionOvercoming the Insufficiency of Intermittent SamplingSamples introduction/extractionTransformerElectric machine

The invention discloses a continuous pressure-variable sampling device for a serpentine mass spectrometer, which includes a housing and a mass spectrometer system. An inner plate with a serpentine groove on the upper surface is slidably installed inside the housing. The serpentine line The cross-sectional area of the groove gradually increases from the inlet end to the outlet end. The gas outlet of the serpentine groove penetrates the side wall of the shell through the connecting pipeline and connects with the mass spectrometer system. The lower surface of the inner plate is supported by springs and bearings. The upper surface of the inner plate is closely attached to the inner upper wall surface of the outer shell with ventilation grooves. The air inlet of the air groove penetrates through the upper wall of the outer shell and is connected with the air inlet pipeline and the air inlet valve. The driving motor is driven by the screw mechanism. The inner plate slides in the shell; the invention has compact structure, good airtightness, and has the ability of continuous online sampling of the gas to be analyzed; through the serpentine layout and the sliding of the inner plate in the shell, the gas path of the serpentine line groove can be changed Length and cross-sectional area, so that it has the ability to sample and analyze a wide range of variable pressure gases with high precision.

Owner:NORTHEASTERN UNIV LIAONING

Space microgravity double-layer suspension vibration isolation device, scientific experiment cabinet and suspension method

ActiveCN114132537BEasy to assembleStable gas pressureCosmonautic condition simulationsMicro gravityVibration isolation

The invention relates to a space microgravity double-layer suspension vibration isolation device, a scientific experiment cabinet and a suspension method. The space microgravity double-layer suspension vibration isolation device includes an air-jet suspension test bench (abbreviated as an outer body), a magnetic levitation test bench (abbreviated as an inner body), and an inner body The body is provided with a magnet, the outer body is provided with an electromagnetic coil, the inner body is embedded in the outer body, the magnet and the electromagnetic coil are arranged correspondingly, and the force generated by the energized coil in the magnetic field is used to control the suspension of the inner body relative to the outer body; The thruster utilizes the jet stream of the thruster to generate thrust to control the suspension of the outer body. The invention realizes the double-layer non-contact movement of the outer body following the inner body from the hardware level, and isolates the disturbance of the basic environment, thereby realizing a high microgravity level.

Owner:TECH & ENG CENT FOR SPACE UTILIZATION CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com