Method for manufacturing dry-mixed mortar anti-segregation silo

A dry-mixed mortar and anti-segregation technology, which is applied in the direction of containers, packaging, transportation and packaging, etc., can solve the problems of dry-mixed mortar segregation, etc., and achieve the effects of reducing segregation, smooth discharge, and avoiding segregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0016] The present invention will be further described below with reference to the accompanying drawings and embodiments.

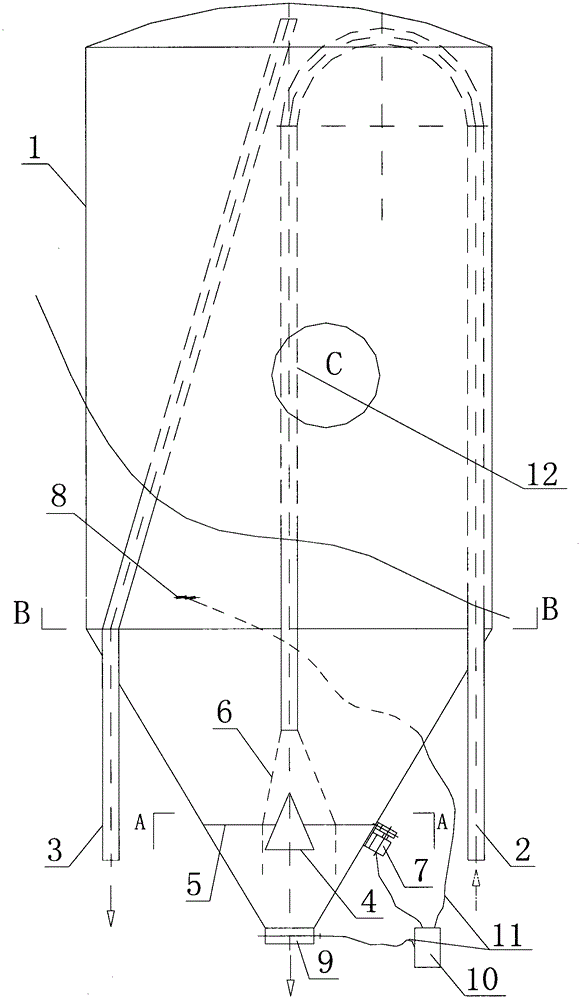

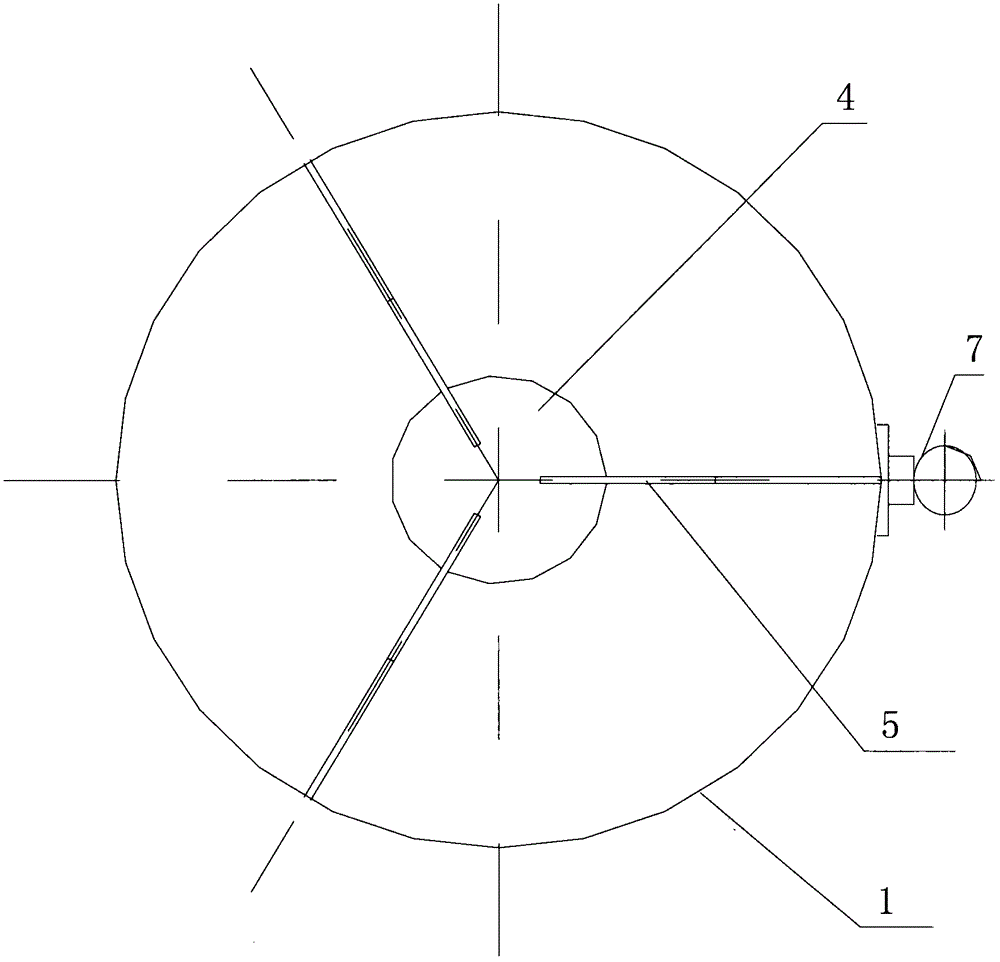

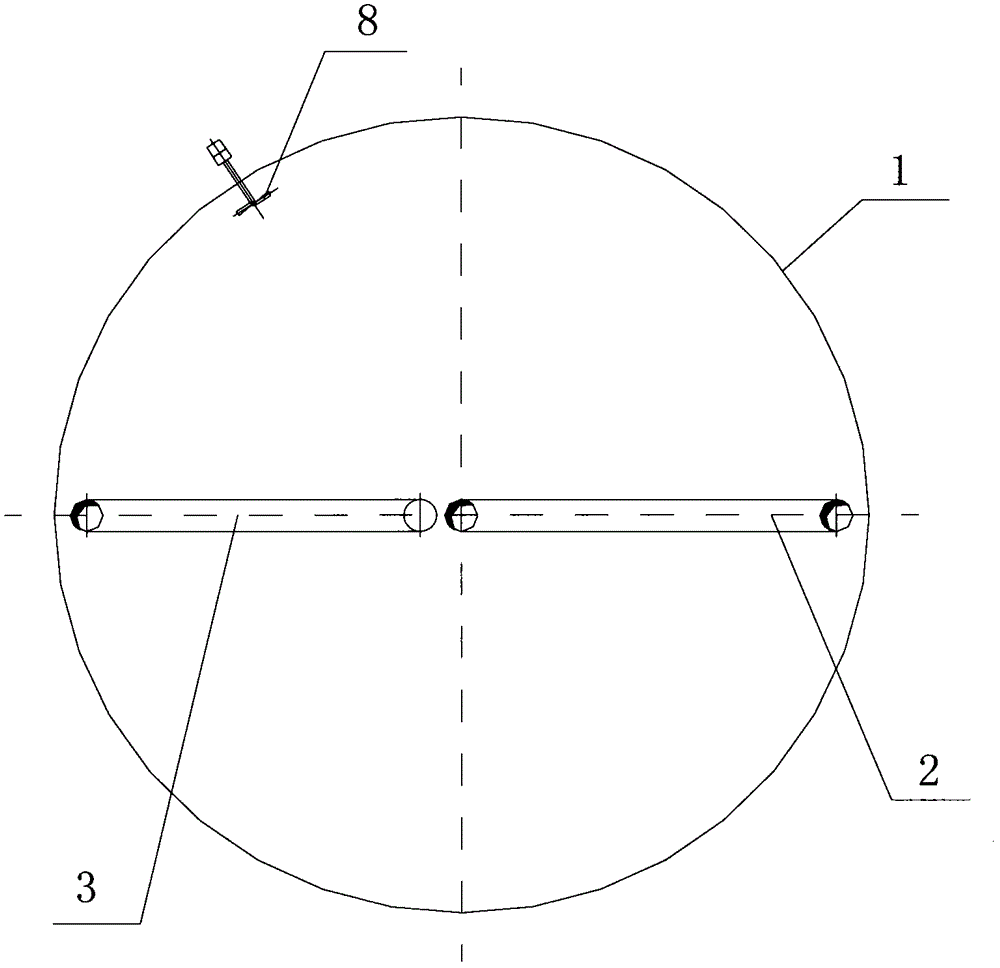

[0017] A method for manufacturing a dry-mixed mortar anti-segregation silo according to the present invention is as follows: the dry-mixed mortar anti-segregation silo is composed of a silo body (1), a feeding pipe (2), an air outlet pipe (3), and a broken arch. Cone (4), arch breaking cone bracket (5), arch breaking chain (6), rapper (7), material level gauge (8), discharge port (9), control system (10) and wires (11) ), the silo silo body (1) is a metal tank body with a cylinder body in the upper middle part and a cone in the lower part; the feed pipe (2) is in an inverted U shape in the tank body, and its inlet is located in the silo silo body ( 1) Outside the side of the lower cone, the outlet is located in the center of the inner lower part of the silo body (1). , while a plurality of openings (12) are evenly distributed on the pipe wall of the desc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com