Hydraulic gas storage cylinder

A gas storage tank, water pressure technology, applied in the field of biomass energy applications, can solve the problems of pool strength lamps, unfavorable stable combustion of stoves, inability to solve short-term peak gas consumption, loss of fermentation liquid between discharges, etc., to achieve gas Stable pressure, simple structure, stable gas storage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

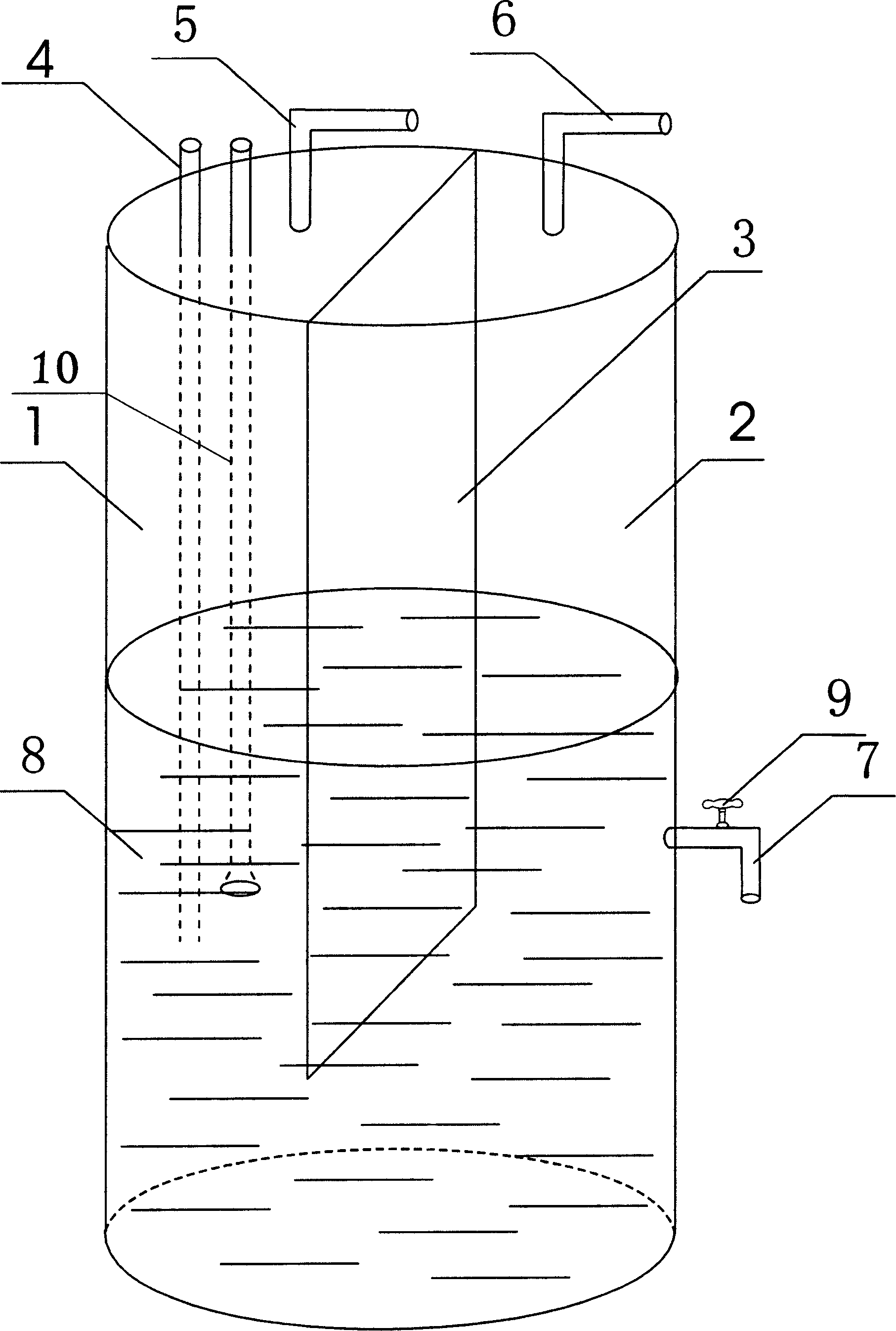

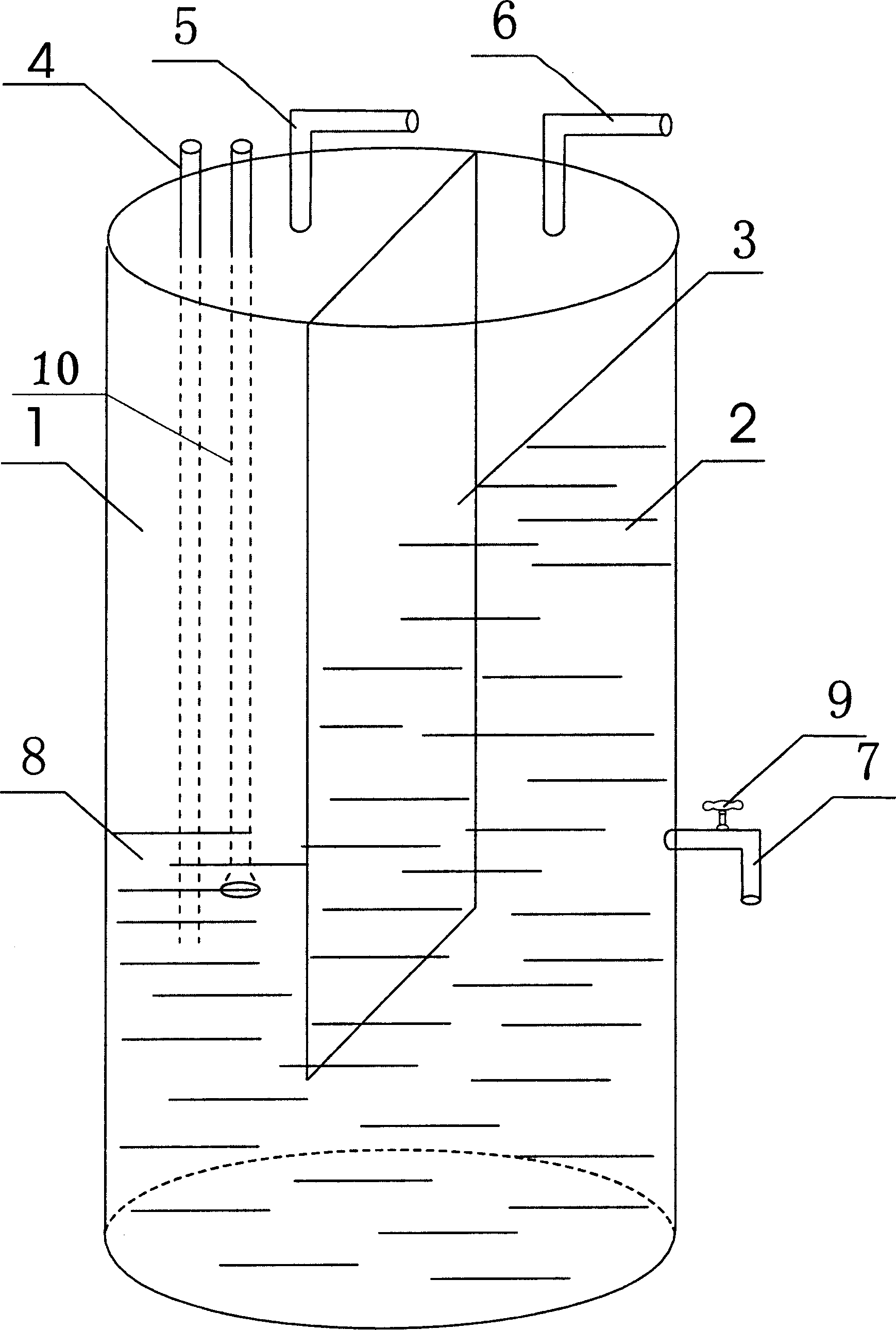

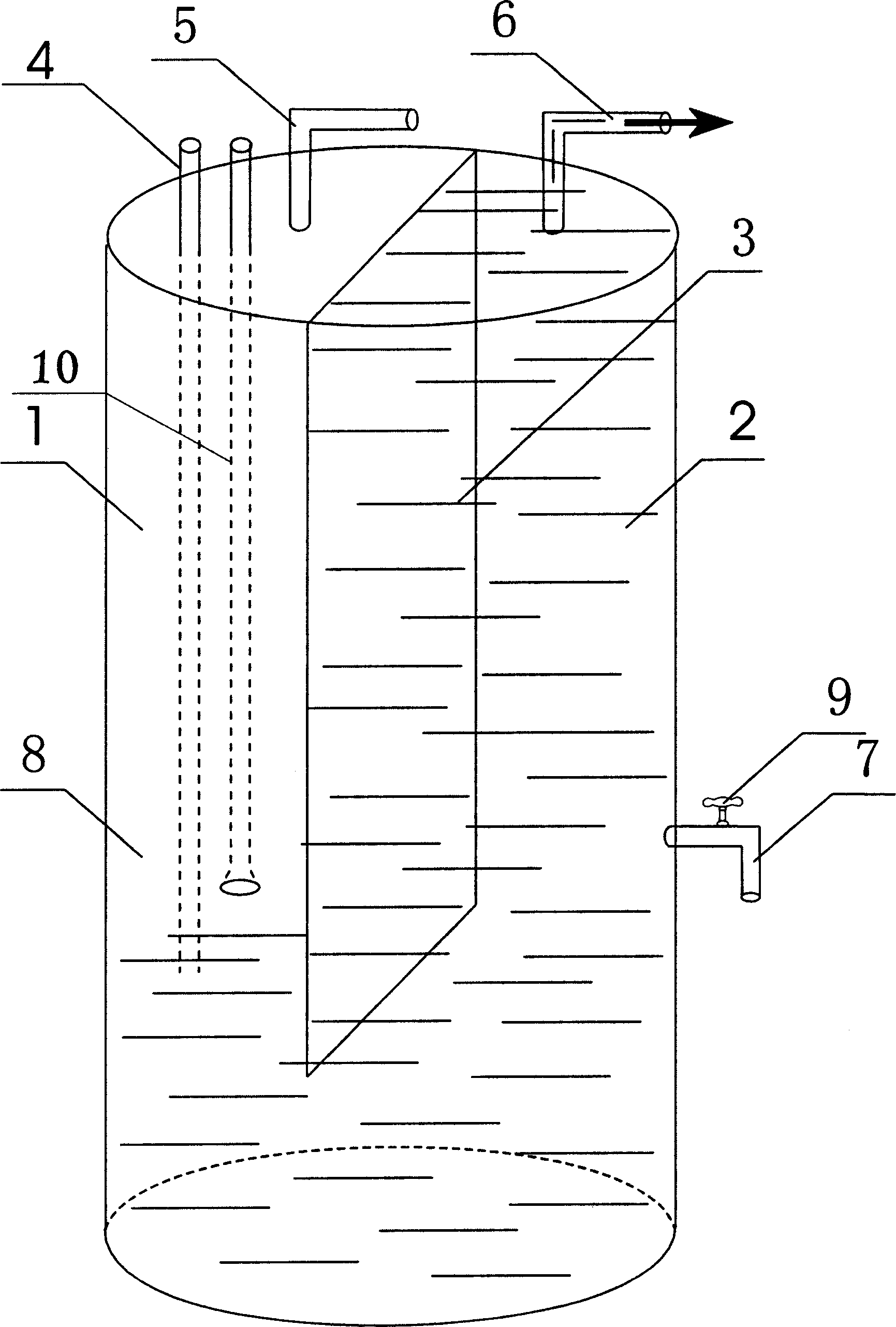

[0018] Such as figure 1 Among them, a partition 3 is provided between the air storage chamber 1 and the water pressure chamber 2, the lower end of the partition 3 is higher than the bottom surface of the tank body, and the top of the water pressure chamber 2 is provided with a water inlet and overflow pipe 6, from which the water inlet overflow pipe Water or solution 8 is injected into 6, and water or solution 8 flows into the air storage chamber 1 from the hydraulic chamber 2 through the lower end of the partition plate 3. Under normal pressure, the water levels in the air storage chamber 1 and the hydraulic chamber 2 are on the same level. When the gas outlet pipe 5 is closed and the shunt pipe 10 extends under the liquid surface, after the fermentation raw materials are decomposed or the stalk is gasified to produce gas, the gas will graduall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com