Apparatus and method for measuring gas mass-transfer diffusivity of film material

A diffusion coefficient and thin-film material technology, applied in the field of thin-film material measurement devices, can solve the problems of accelerating gas transmission rate, impossibility, inaccurate measurement data, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

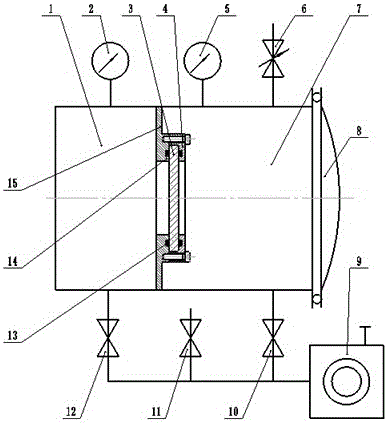

[0049] The present invention will be described in detail below in conjunction with the embodiments shown in the accompanying drawings.

[0050] In the figure: 1-measurement chamber, 2-vacuum gauge in the measurement chamber, 3-flange blind plate or test sample, 4-flange gland, 5-inflatable chamber pressure gauge, 6-pressure control regulating valve, 7-inflatable Chamber, 8-inflatable chamber door, 9-vacuum pump, 10-inflatable chamber valve, 11-deflation valve, 12-measurement chamber valve, 13-sealing ring, 14-sealing flange, 15-middle partition.

[0051] The device of the present invention is made up of following parts: two parallel vacuum chambers---measuring chamber 1 and air-filling chamber 7 that have measured background air leakage rate, are separated by a vacuum chamber body and utilize middle partition 15 to form, middle partition A round hole is set on the plate as an air extraction channel and a sealing flange 14 is provided. The sealing flange 14 faces the side of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com