A V-shaped Diesel Engine Constant Pressure Sequential Supercharging System

A technology of successive supercharging and diesel engines, applied in mechanical equipment, engine components, combustion engines, etc., can solve the problems of large intake pipeline layout space, increased throttling loss, and many auxiliary devices, etc., to promote work stability, The effect of stabilizing gas pressure and improving compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

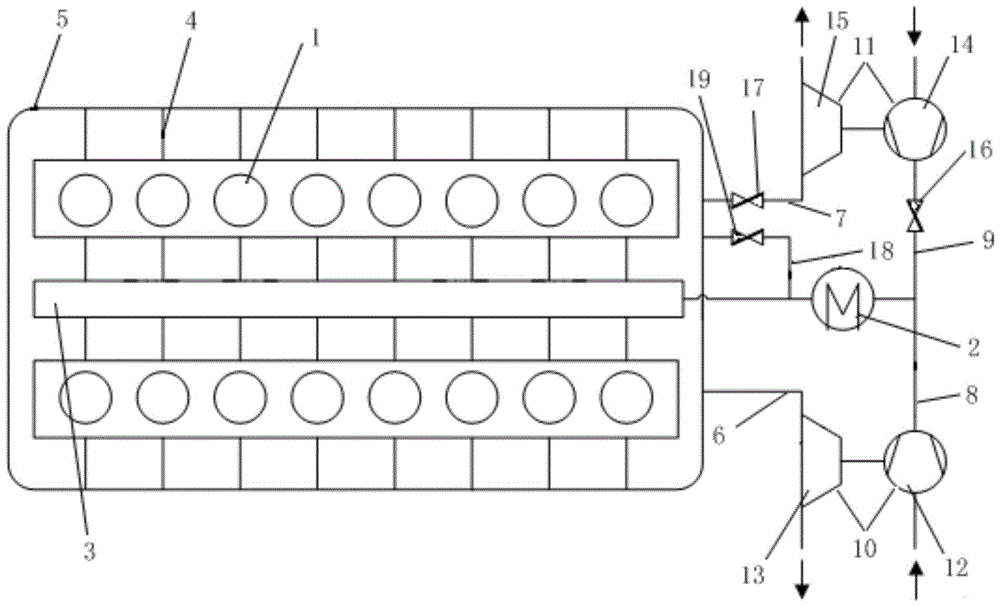

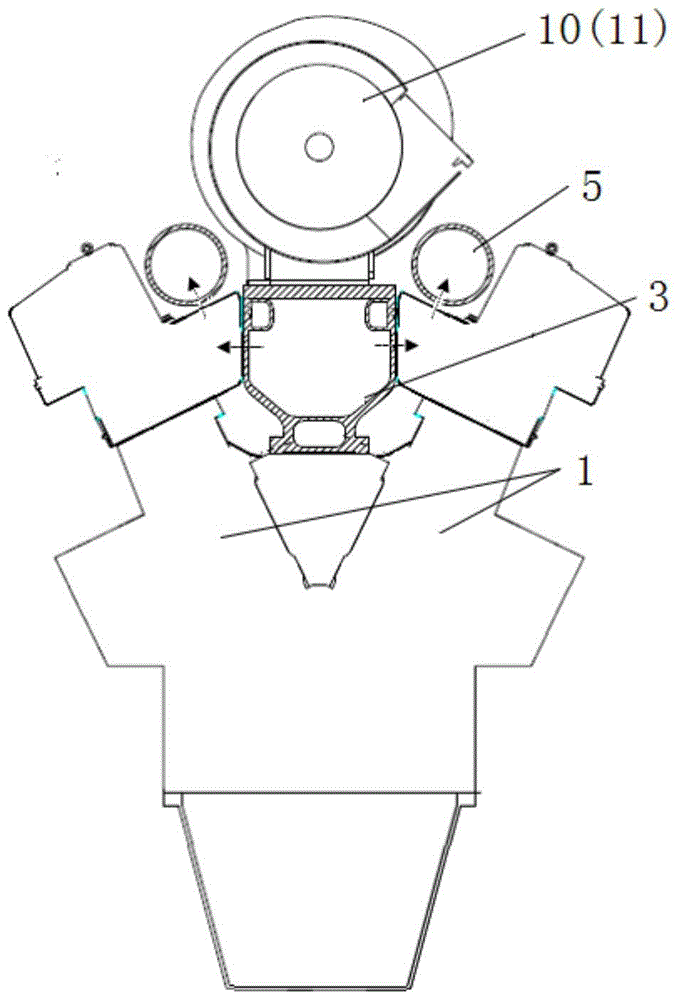

[0034] Such as figure 1 As shown, a preferred embodiment of the V-type diesel engine constant pressure sequential supercharging system of the present invention includes: two rows of cylinders composed of a plurality of cylinders 1, an air cooler 2, a common air intake box 3, exhaust branch pipes 4, constant pressure Exhaust manifold 5, first rear exhaust pipe 6, second rear exhaust pipe 7, first intake pipe 8, second intake pipe 9, first turbocharger 10, second turbocharger 11; wherein , the first turbocharger 10 includes a first compressor 12 arranged in the first intake pipe 8 and a first turbine 13 arranged in the first rear exhaust pipe 6, and the second turbocharger 11 includes a The second compressor 14 in the second intake pipe 9 and the second turbine 15 arranged in the second rear exhaust pipe 7; in addition, the second intake pipe 9 is also provided with an intake cut-off valve 16, the second rear row An exhaust cut-off valve 17 is also arranged in the air pipe 7 . ...

Embodiment 2

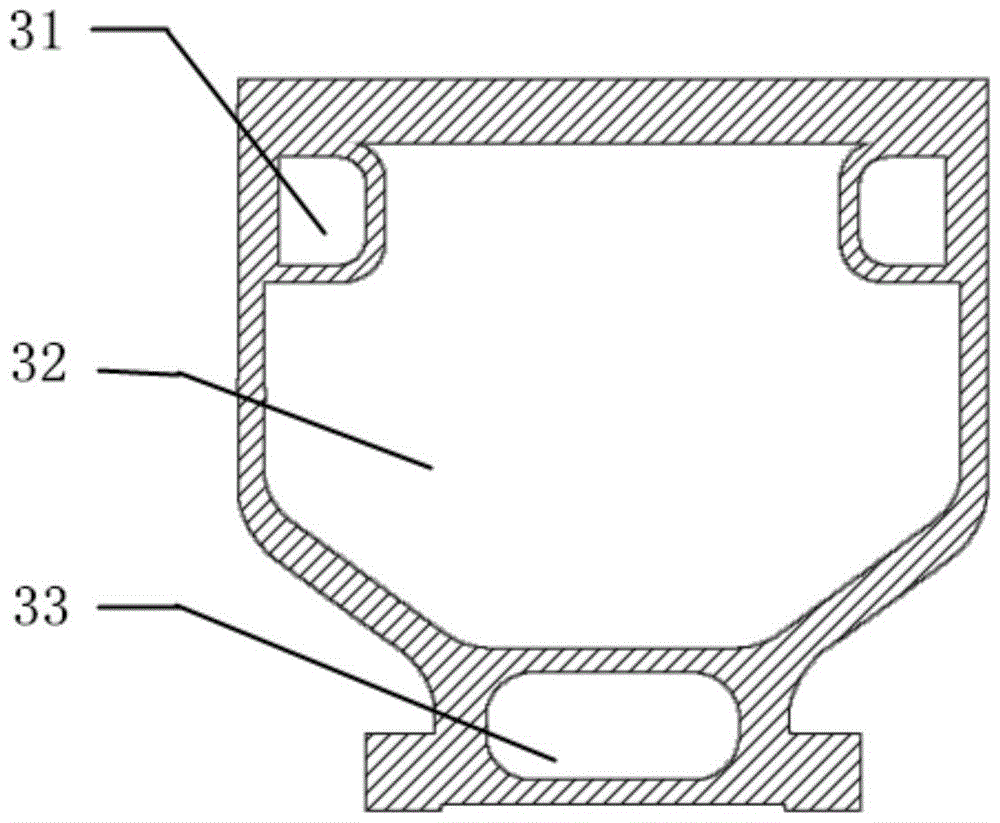

[0039] Such as image 3 As shown, the common air intake box 3 of the present embodiment is specially designed: the top of the common air intake box 3 is a plane, and the two sides of the lower part along the axial direction (air flow direction) are inclined planes, and a foot seat is also included; After cooling, it enters the common air intake chamber 32. In addition, it also integrates the cylinder head high-temperature water drainage main pipe 31 and the cylinder head high-temperature water inlet main pipe 33. The cylinder head high-temperature water drainage main pipe 31 is divided into left and right two, corresponding to the left and right Two banks of cylinders. This design can improve the compactness of the diesel engine layout, and the cylinder head high-temperature water drainage main pipe 31, the common air intake chamber 32 after the intercooler and the cylinder head high-temperature water inlet main pipe 33 have a unified installation plane with the cylinder head,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com