Sample cracking voltage stabilizer

A voltage stabilizing device and sample technology, applied in the preparation of test samples, analysis materials, instruments, etc., can solve the problems of non-linearity of test results, unstable gas pressure, insufficient reaction time, etc., and achieve signal value fluctuation factors drop, stable gas pressure, and the effect of solving the problem of carbon deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

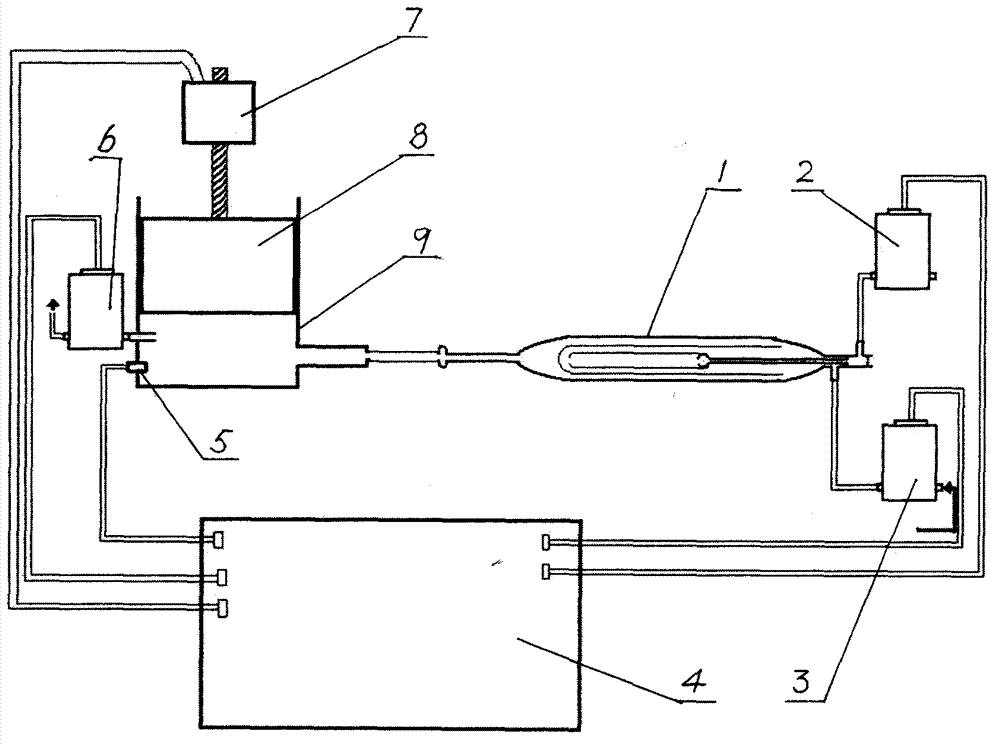

[0008] Referring to the accompanying drawings, the sample cracking and voltage stabilizing device used for element content detection includes a high-temperature cracking furnace (not shown in the figure) and a quartz tube, wherein the quartz tube 1 is a blind sleeve type quartz tube, and its argon inlet and oxygen inlet are connected respectively. There are mass flow meters 2 and 3, the sample gas outlet of the quartz tube is provided with a gas buffer device consisting of a cylinder 9, a piston 8 and a stepping motor 7 connected to the piston, the outlet of the cylinder is connected to the mass flow meter 6, and the inside of the cylinder is close to the outlet There is a gas pressure detector 5, and the mass flowmeters 2, 3 and 6, the gas pressure detector 5, and the stepper motor 7 are all connected to the computer control board 4. In this embodiment, the pressures of mass flowmeters 2 and 3 are controlled by computer to be 0.2MPa, and argon and oxygen are input into the qua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com