Gas pressure control system and method

A gas pressure and control system technology, applied in the field of automobile manufacturing, can solve the problems of easily damaged diaphragms, affecting the reaction efficiency of fuel cells, and difficult sealing of stacks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

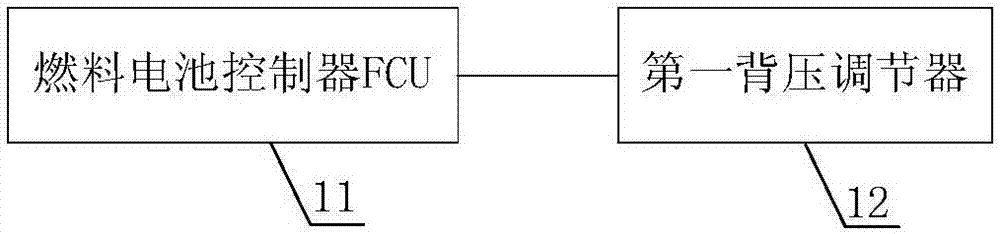

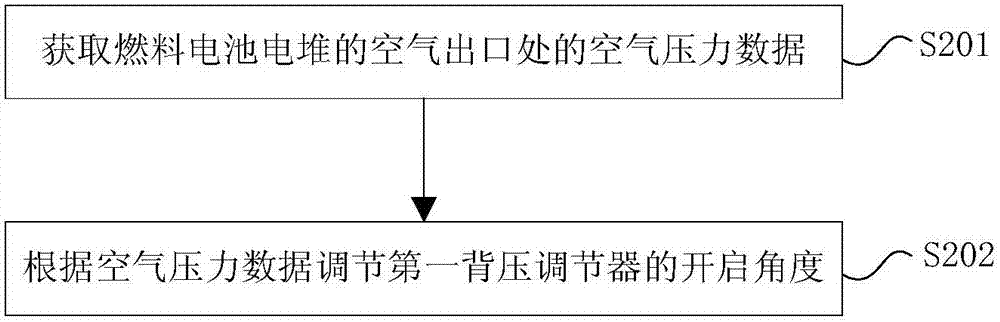

[0033] This embodiment provides a gas pressure control system, figure 1 is a structural block diagram of a gas pressure control system according to an embodiment of the present invention, such as figure 1 As shown, it includes a fuel cell controller FCU11 and a first back pressure regulator 12, wherein the first back pressure regulator 12 is connected to the FCU11, the first back pressure regulator 12 is installed at the air outlet of the fuel cell stack, and the FCU11 It is used to obtain the air pressure data at the air outlet of the fuel cell stack, and adjust the opening angle of the first back pressure regulator 12 according to the air pressure data. For example, in a hydrogen fuel cell, a first back pressure regulator 12 is installed at the outlet of the air channel of the stack. When the output power of the fuel cell decreases, the air input flow decreases, resulting in the air pressure at the outlet of the fuel cell stack. The data decreases. When the air pressure dat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com