Laser polishing and laser shock peening manufacturing methods for welded or additively repaired areas

A technology of laser shock strengthening and laser polishing, which is applied in the fields of welding or additive repair of metal materials, surface treatment and strengthening after welding or repair, and can solve problems such as difficult to achieve high-quality manufacturing, so as to improve the surface quality of workpieces and reduce roughness , the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

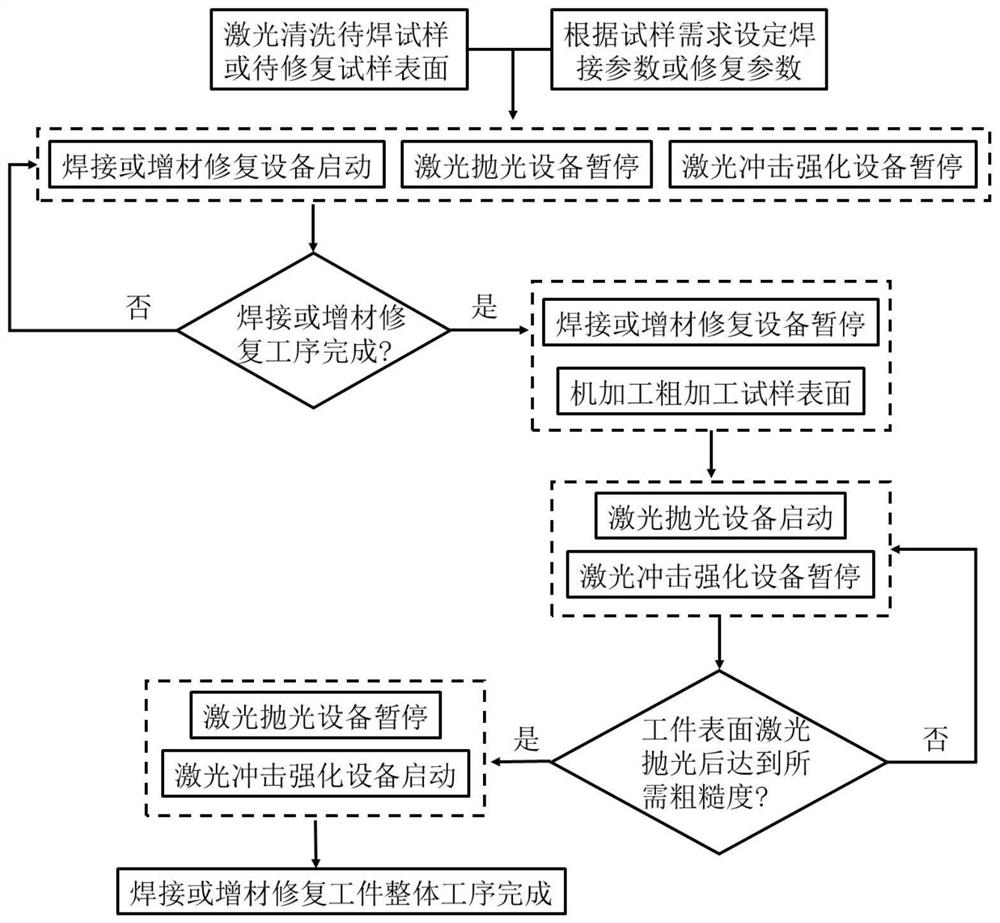

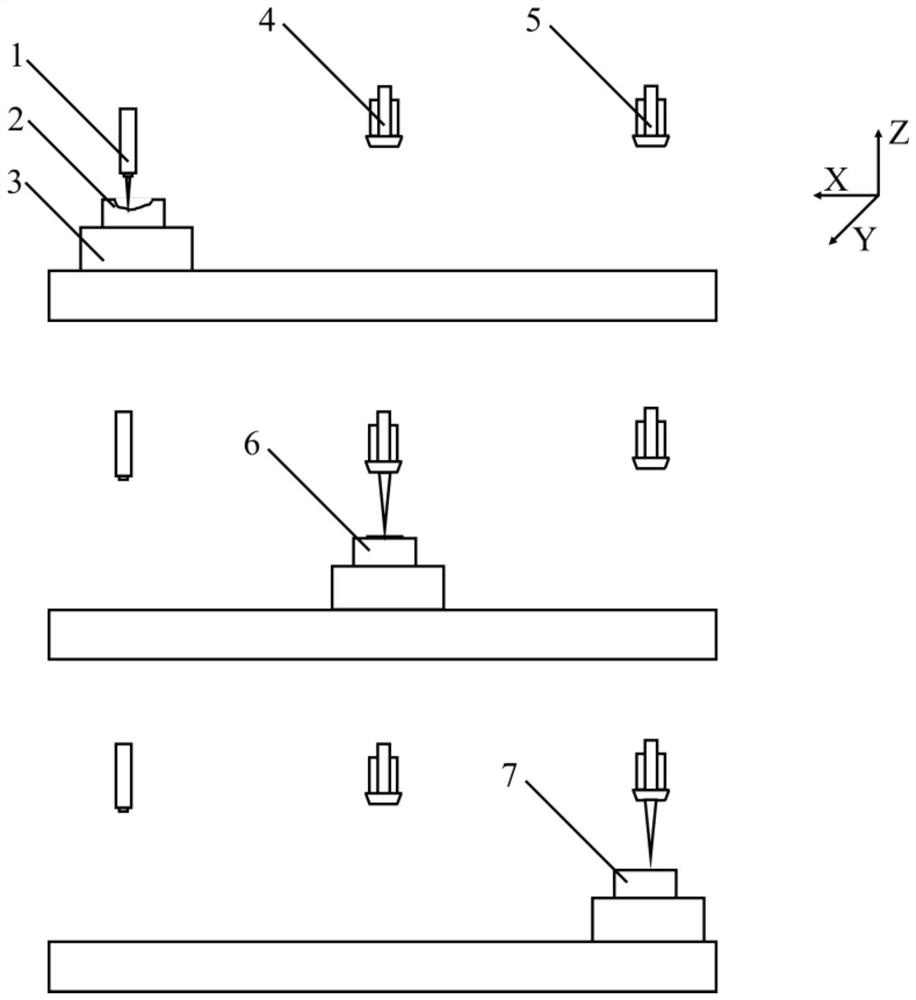

[0026] The embodiment of the present invention takes the realization of arc additive repairing of the overall blisk (taking the GE90 engine compressor as an example, the material used: TC17 titanium alloy) as an example, combining arc additive technology, laser polishing technology and laser shock strengthening. The method flow is as follows figure 1 As shown, the specific steps are as follows:

[0027] Step 1: Use 200-mesh, 400-mesh, 800-mesh, 1500-mesh and 2500-mesh sandpaper in sequence to polish the workpiece 2 to be repaired by additives, then place it in acetone for ultrasonic cleaning to remove impurities and oil on the surface of the workpiece, and then place it in a 120°C oven Dry in medium for 1 hour; place the cleaned workpiece to be repaired on the CNC workbench 3 for positioning and clamping.

[0028] Step 2, according to the size of the workpiece to be repaired, import the 3D model of the additive repair into the equipment; set the parameters of the arc additive...

Embodiment 2

[0036] In the embodiment of the present invention, taking the realization of arc additive repairing of aircraft engine turbine blades (the material used: TC17 titanium alloy) as an example, the arc additive technology, laser polishing technology and laser shock strengthening are combined. The method flow is as follows figure 1 As shown, the specific steps are as follows:

[0037] Step 1: Use 200-mesh, 400-mesh, 800-mesh, 1500-mesh and 2500-mesh sandpaper in sequence to polish the workpiece 2 to be repaired by additives, then place it in acetone for ultrasonic cleaning to remove impurities and oil on the surface of the workpiece, and then place it in a 120°C oven Dry in medium for 1 hour; place the cleaned workpiece to be repaired on the CNC workbench 3 for positioning and clamping.

[0038] Step 2, according to the size of the workpiece to be repaired, import the 3D model of the additive repair into the equipment; set the parameters of the arc additive equipment: welding current...

Embodiment 3

[0043] In the embodiment of the present invention, taking electric arc additive repairing of automobile pedals (the material used: carbon steel) as an example, the arc additive technology, laser polishing technology and laser shock strengthening are combined, and the method flow is as follows figure 1 As shown, the specific steps are as follows:

[0044] Step 1: Use 200-mesh, 400-mesh, 800-mesh, 1500-mesh and 2500-mesh sandpaper in sequence to polish the workpiece 2 to be repaired by additives, then place it in acetone for ultrasonic cleaning to remove impurities and oil on the surface of the workpiece, and then place it in a 120°C oven Dry in medium for 1 hour; place the cleaned workpiece to be repaired on the CNC workbench 3 for positioning and clamping.

[0045] Step 2. According to the size of the workpiece to be repaired, set the parameters of the arc additive equipment: welding current 120A, welding speed 150mm / min, wire feeding speed 1500mm / min, wire diameter 1.6mm, fro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com