Copper/aluminum ultrasonic liquid-phase diffusion brazing process and brazing device

A technology of liquid phase diffusion and brazing technology, which is applied in auxiliary devices, metal processing, manufacturing tools, etc., can solve problems such as ultrasonic brazing difficulties, and achieve the effects of simple structure, ingenious design, and low brazing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

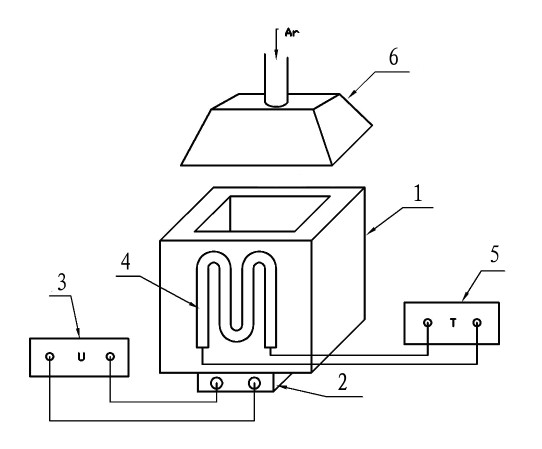

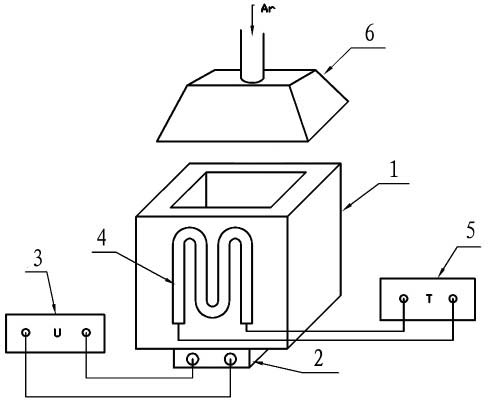

[0017] In order to clearly illustrate the technical characteristics of this solution, the following describes the solution through a specific implementation.

[0018] As shown in the figure, an ultrasonic liquid phase diffusion brazing process for copper / aluminum joints is characterized in that the aluminum wire is cleaned first, the outer paint layer of the aluminum wire is polished with a polyester wheel, and the aluminum wire is wiped clean with acetone; Dip the cleaned aluminum wire into the molten Sn-9Zn eutectic solder, and coat the surface of the aluminum wire with a layer of solder under the action of ultrasonic wave; crimp the solder-coated part of the aluminum wire on the copper terminal; Finally, immerse the part to be welded into the molten Sn-9Zn eutectic solder for ultrasonic liquid phase diffusion brazing. The welding time is maintained for 2-5 seconds. During the welding process, the solder and the workpiece are both in argon gas flow. Air cooling. Wherein, the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com