Early-warning system capable of preventing magnetic material cracks

An early warning system, magnetic material technology, applied in the direction of material magnetic variables, etc., can solve the problems of ferromagnetic materials that are prone to cracks, potential safety hazards, and limited

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

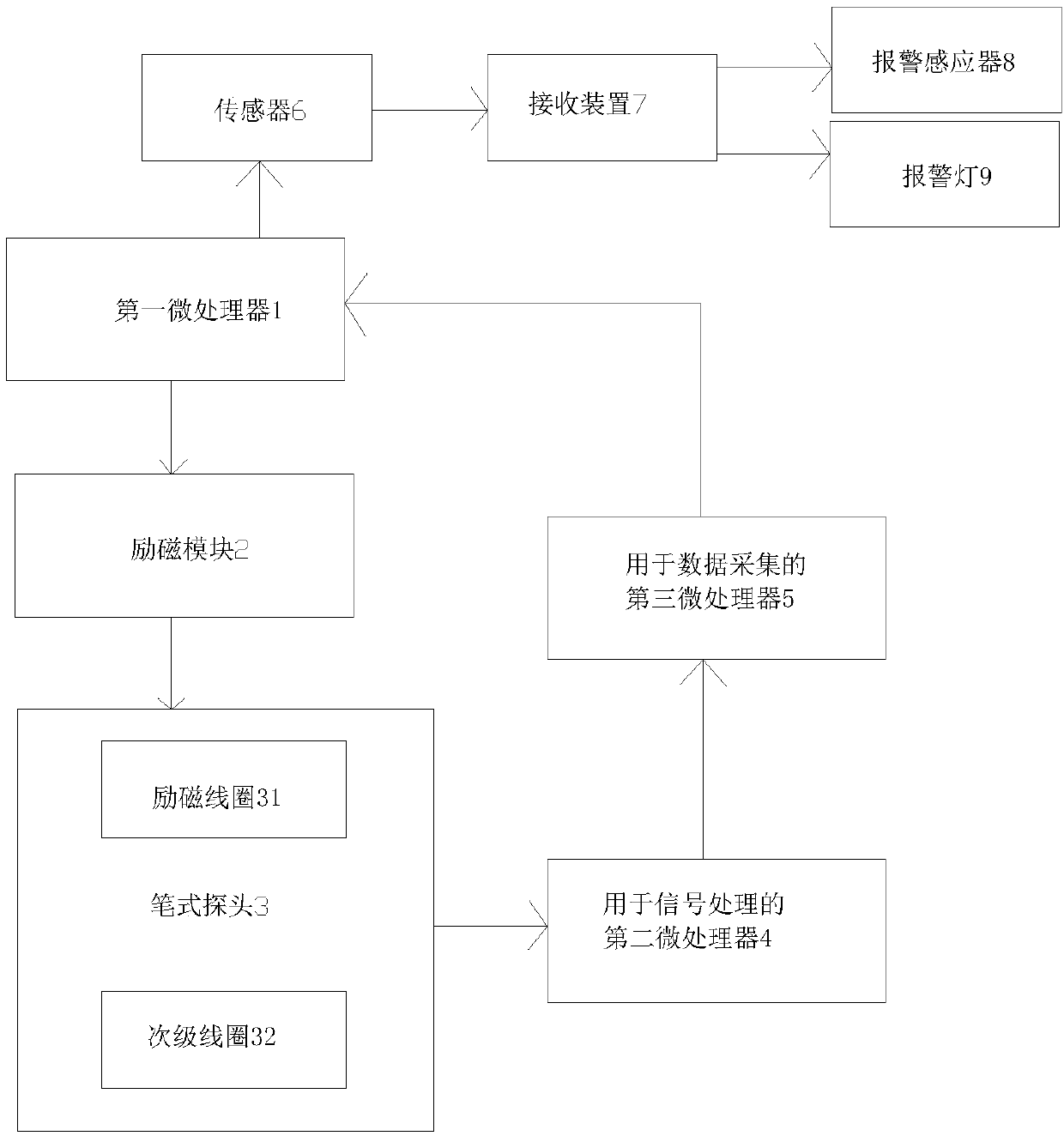

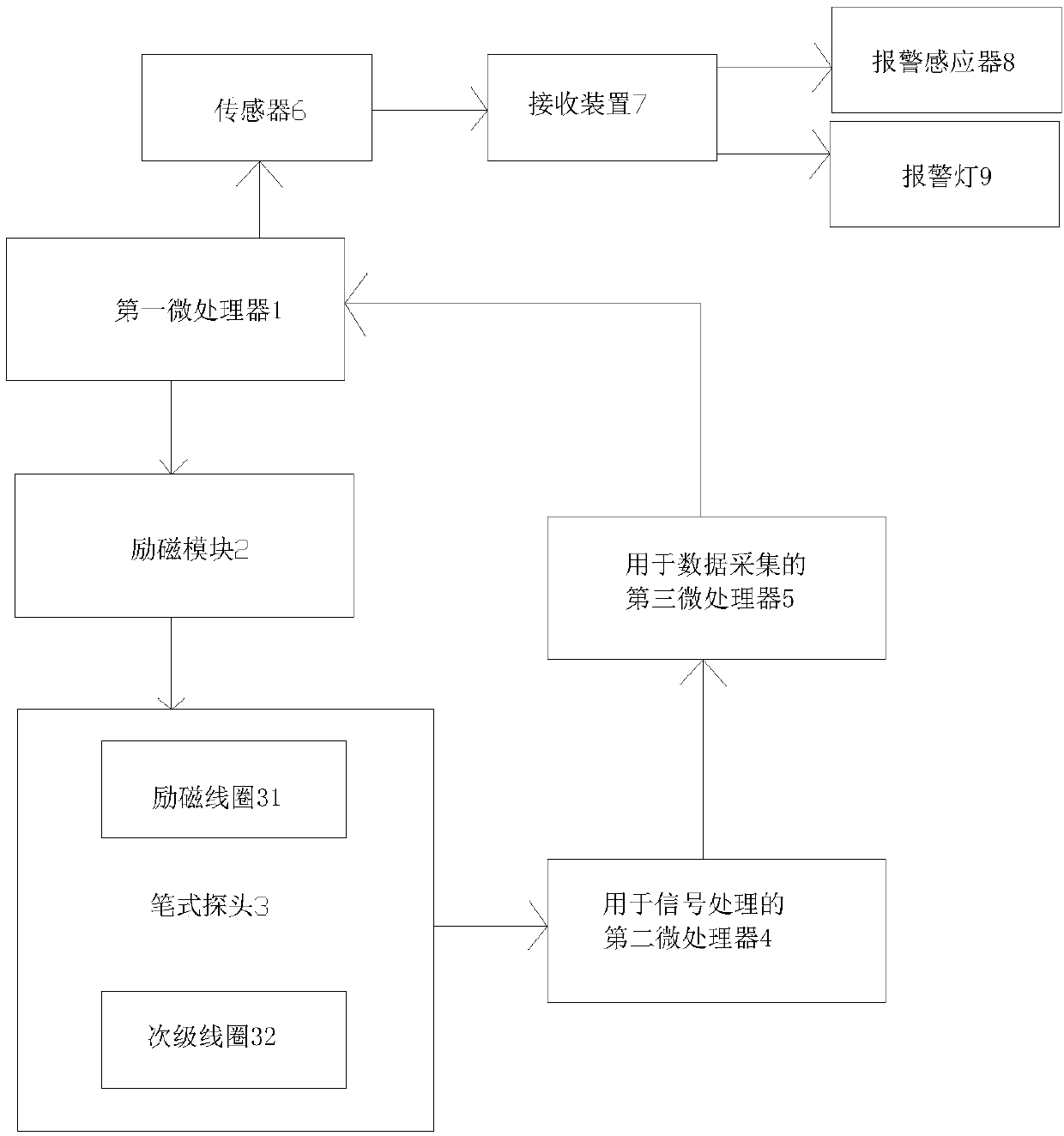

[0014] As shown in the figure, it includes a first microprocessor 1, an excitation module 2, a pen probe 3, a second microprocessor 4 for signal processing and a third microprocessor 5 for data acquisition;

[0015] The output end of the first microprocessor 1 is connected to the input end of the excitation module 2, the output end of the excitation module 2 is connected to the input end of the pen probe 3, and the output end of the pen probe 3 is connected for signal processing The input end of the second microprocessor 4, the output end of the second microprocessor 4 for signal processing is connected to the input end of the third microprocessor 5 for data acquisition, and the input end for data acquisition The output end of the third microprocessor 5 is connected to the input end of the first microprocessor 1;

[0016] The input end of described first microprocessor 1 is also connected with automatic early warning device, and described automatic early warning device compris...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com