Device and method of monitoring steel rail temperature stress in real time based on laser ultrasonic method

A technology of laser ultrasound and temperature stress, which is applied in the measurement, transportation and packaging of the material by measuring the change of its optical properties when it is stressed, and the railway vehicle shape measuring device, etc., can solve the problem of coupling agent, high surface requirements, and high efficiency. Low-level problems, to achieve the effect of fast detection speed and low surface requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

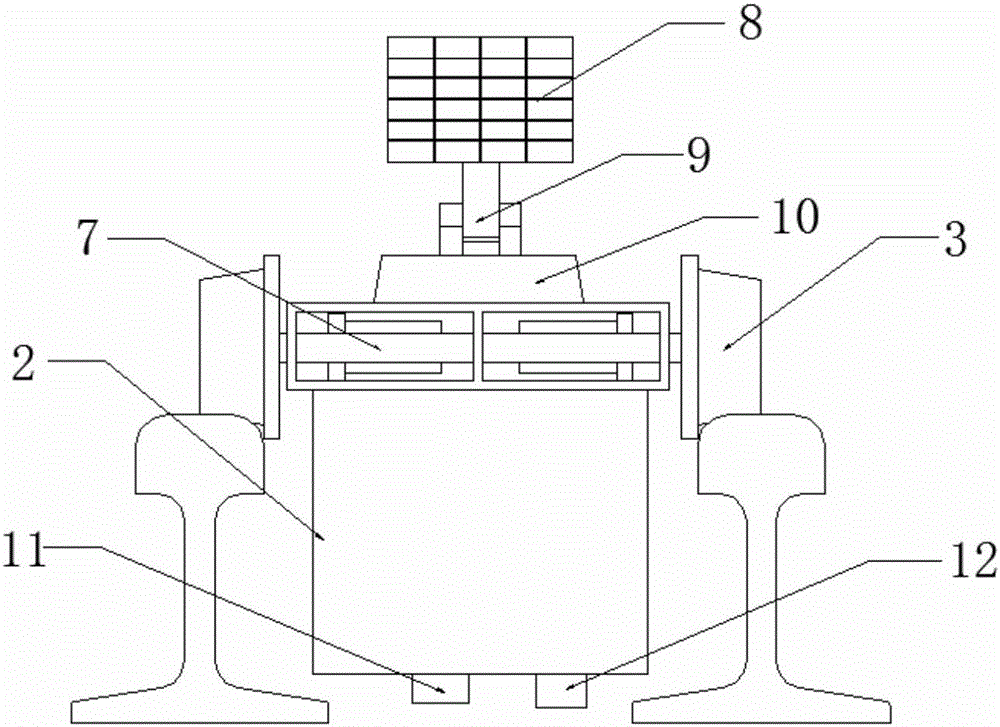

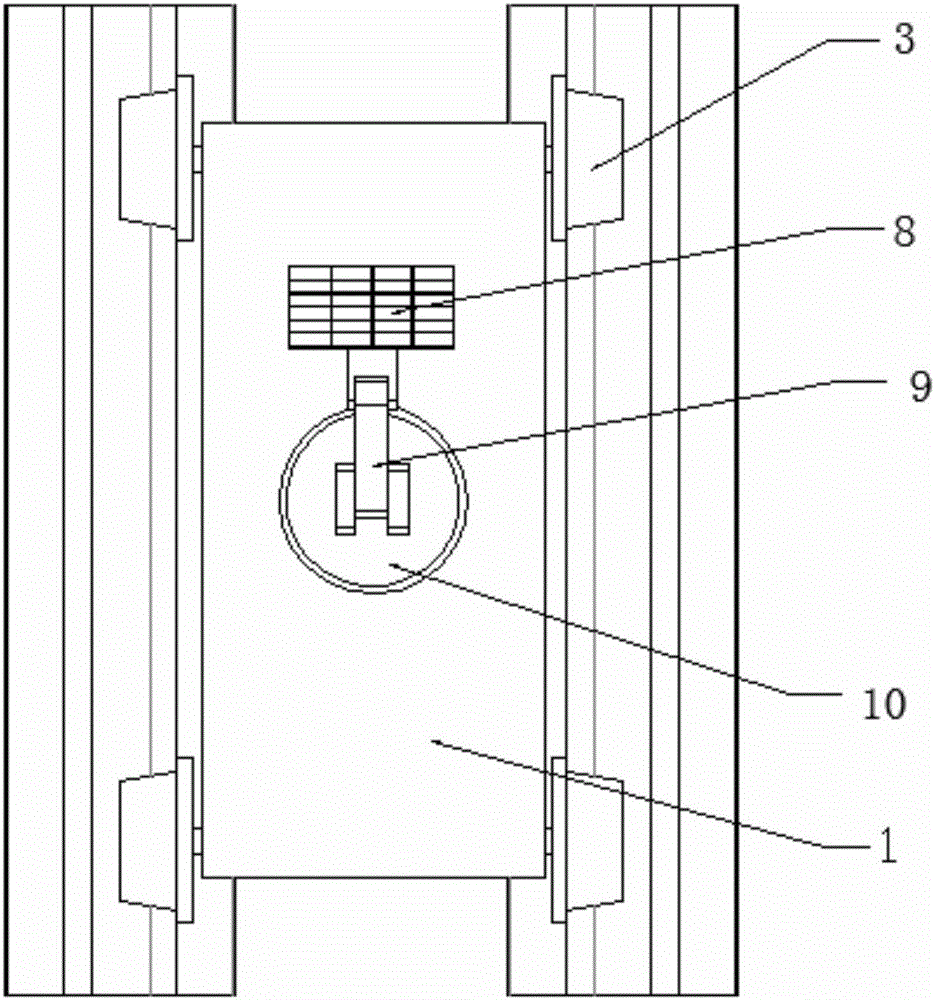

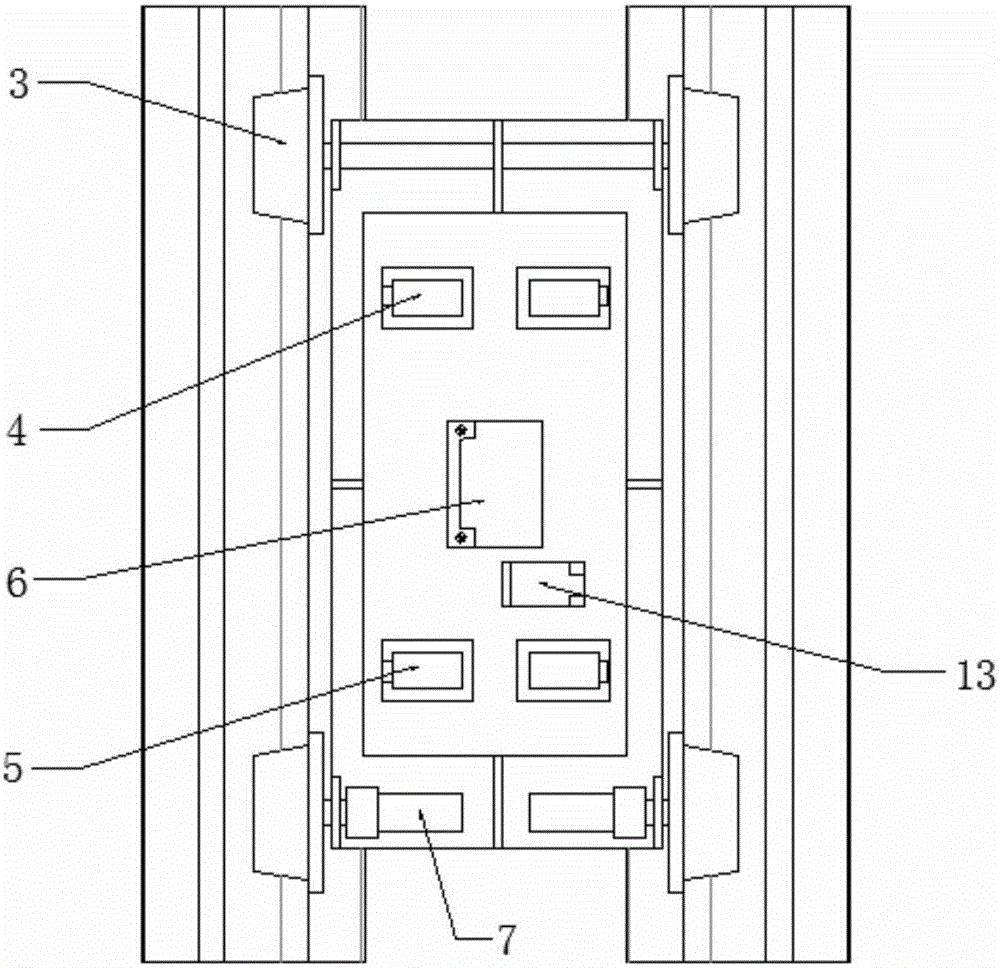

[0028] Such as Figure 1~4 As shown, the device for real-time monitoring of rail temperature stress based on the laser ultrasonic method includes a monitoring car and a power supply group. The monitoring car includes the upper body 1, the lower body 2, the wheels 3, the positioner 11 and the temperature measuring instrument 12, and the upper body 1 is connected to the lower body Body 2, wheels 3 are installed on both sides of the upper body 1 through axles, and the positioner 11 and temperature measuring instrument 12 are installed on the bottom of the lower body 2; the power supply group includes solar panels 8, solar support frames 9, turntables 10, and solar controllers 13 and battery 6, solar panel 8, solar support frame 9, turntable 10 are installed on the top of upper body 1, solar controller 13 and battery 6 are placed in lower body 2, solar panel 8 is connected to solar controller 13, solar controller 13 is connected to the battery 6; a motor 7 is installed in the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com